Maintenance essentials for ensuring effective brake calipers

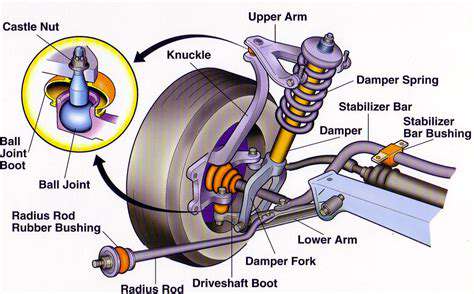

Visual Inspection: A Quick Check

When assessing your brake pads' condition, start with a thorough visual examination. This initial check often reveals critical issues before they escalate. Focus on the pad surfaces, looking for uneven wear, deep grooves, or unusual discoloration. These visual cues can indicate potential problems that might require immediate attention.

Don't overlook the brake rotors during this inspection. Metal shavings or deep scoring on the rotor surface often signal underlying issues with the braking system. Catching these problems early can prevent expensive repairs down the road and maintain your vehicle's stopping power.

Measuring Pad Thickness: Ensuring Safety

While visual checks provide valuable information, precise measurements tell the complete story. Use a dedicated brake pad gauge to determine the exact remaining material thickness. Most manufacturers specify minimum thickness levels for safe operation - falling below these limits dramatically reduces braking effectiveness.

Regular thickness measurements form the foundation of proactive brake maintenance. This simple practice helps you anticipate replacement needs before performance suffers, keeping you safe on the road.

Examining Brake Rotor Condition: Important Considerations

Brake rotors work in tandem with pads, so their condition directly impacts stopping performance. Look for warping, deep grooves, or excessive wear on the rotor surfaces. These issues can cause vibration during braking and reduce your vehicle's stopping power.

Understanding Wear Patterns: Identifying Issues

Uneven pad wear often reveals hidden problems. Consistent wear on one side might indicate alignment issues, while erratic patterns could point to caliper problems. Learning to interpret these patterns helps diagnose underlying issues before they cause major damage.

Regular wear pattern analysis serves as an early warning system for your braking system. This practice can extend component life and prevent sudden failures.

Considering Driving Habits: Impact on Brake Pad Life

Your driving style significantly affects brake wear. Frequent hard stops, aggressive driving, and towing heavy loads all accelerate pad deterioration. Recognizing these factors helps you adjust maintenance schedules accordingly.

Professional Inspection: When to Seek Help

While DIY checks are valuable, some situations demand professional expertise. Complex issues or uncertainty about your findings warrant a mechanic's trained eye. Their comprehensive evaluation can identify problems you might miss and ensure your braking system operates at peak performance.

Cleaning Brake Calipers for Pristine Functionality

Preparing the Workspace

Begin by setting up in a well-ventilated area, as brake dust contains harmful particles. Gather all necessary supplies - soapy water, brushes, cleaning solutions, and protective gear. Proper preparation makes the cleaning process safer and more effective.

Disassembling the Brake Calipers

Carefully remove calipers according to your vehicle's service manual. Pay close attention to brake line connections and mounting hardware. Accurate disassembly prevents damage and ensures proper reassembly.

Cleaning the Brake Pads

Thoroughly scrub pads with a stiff brush and soapy water, removing all accumulated dust and debris. Clean contact surfaces are essential for optimal braking performance and pad longevity.

Cleaning the Brake Caliper Components

Use specialized brake cleaner on all caliper parts, focusing on pistons and mounting brackets. Allow cleaner to penetrate before scrubbing stubborn deposits, then rinse completely to remove all residue.

Inspecting for Damage

Examine all components for cracks, corrosion, or excessive wear. Never reinstalled damaged parts - they compromise safety and braking effectiveness. Replace any questionable components immediately.

Reassembling and Final Checks

Reinstall all components carefully, following torque specifications. After reassembly, test brakes thoroughly before regular driving. Any unusual noises or sensations warrant immediate professional inspection.

Lubricating Brake Calipers and Associated Components: Ensuring Smooth Operation

Lubrication Importance

Proper caliper lubrication prevents sticking and ensures responsive braking. Without adequate lubrication, components seize, reducing braking effectiveness and creating safety hazards. Regular lubrication extends the life of your entire braking system.

Identifying the Right Lubricant

Always use lubricants specifically designed for brake systems. Incorrect products can damage components or fail under high temperatures, potentially causing brake failure. Consult your manual or mechanic for product recommendations.

Proper Lubrication Technique

Apply lubricant sparingly to sliding surfaces and pivot points. Excess lubricant attracts dirt and can contaminate brake pads, reducing their effectiveness. Clean components thoroughly before application for best results.

Calipers and Rotors

Well-lubricated calipers allow rotors to function optimally. This synergy ensures smooth, vibration-free braking and prevents premature wear on both components.

Maintaining Brake Pads

Regular pad inspection complements lubrication efforts. Worn pads increase stress on calipers, making proper lubrication even more critical for system longevity.

Safety Considerations

Always secure the vehicle properly before working on brakes. Use jack stands for support - never rely solely on a jack. Wear protective gear to shield against chemicals and dust.

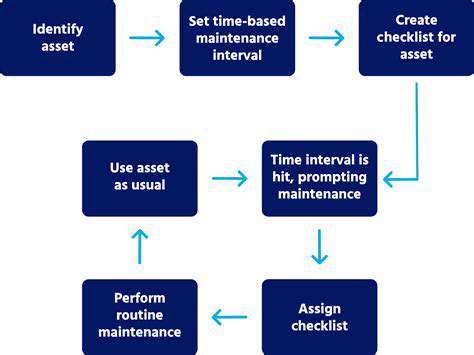

Frequency of Maintenance

Lubrication intervals vary by driving conditions. Severe service (towing, mountain driving) requires more frequent attention than normal commuting. Follow manufacturer recommendations for your specific vehicle.

Routine Maintenance and Professional Inspections: Proactive Safety Measures

Preventive Measures

Consistent maintenance prevents most braking system failures. Establish a regular schedule for inspections, cleaning, and lubrication. This proactive approach saves money and ensures reliable performance when you need it most.

Professional Expertise

Complex brake issues require trained technicians. Their specialized tools and knowledge identify problems DIYers often miss, preventing minor issues from becoming major repairs.

Tools and Techniques

Proper tools make maintenance easier and safer. Invest in quality equipment or visit a professional shop for comprehensive service. Correct techniques prevent damage during maintenance procedures.

Impact on Efficiency

Well-maintained brakes stop more effectively with less pedal effort. This efficiency translates to better fuel economy and reduced wear on related components throughout your vehicle.