Understanding and addressing irregular vibrations in vehicle cabins

Tire Condition and Inflation

Proper tire condition and inflation are paramount for safe and efficient vehicle operation. Tires that are worn or damaged significantly impact handling and braking, posing a significant safety hazard. Inspecting your tires regularly for tread depth, cuts, bulges, or uneven wear is crucial. Look for irregular wear patterns that could indicate an alignment issue or other underlying problems. Proper inflation is equally important; under-inflation leads to increased rolling resistance, reduced fuel efficiency, and uneven tire wear, while over-inflation can result in decreased ride comfort and reduced contact with the road surface, potentially leading to a loss of control. Always refer to your owner's manual for the recommended tire pressure for your vehicle.

Maintaining the correct tire pressure is essential to prevent tire failure and ensuring a comfortable ride. Regular checks and timely adjustments are vital to prevent accidents. Modern vehicles often have tire pressure monitoring systems (TPMS) to alert drivers to low tire pressure, offering proactive measures for maintaining tire health and safety. Taking proactive steps, such as regular tire checks, will significantly reduce the risk of accidents and maintain the lifespan of your tires.

Wheel Alignment

Proper wheel alignment ensures that your tires maintain optimal contact with the road, maximizing traction and fuel economy. Improper alignment can result in uneven tire wear, causing premature tire failure, and potentially leading to compromised handling and braking performance. It also has the potential to reduce the lifespan of the vehicle's suspension system. Therefore, regular alignment checks are essential for both safety and the longevity of your vehicle.

Misaligned wheels can lead to various issues, affecting the overall performance and efficiency of your vehicle. Significant misalignment can also impact the stability of the vehicle, especially at higher speeds. This can manifest in the steering wheel pulling to one side, vibrating or shaking during driving, or the car pulling to one side. Driving with misaligned wheels can lead to unpredictable handling, potentially increasing the risk of an accident.

Wheel Hubs and Bearings

The wheel hubs and bearings are crucial components that facilitate the smooth rotation of your wheels. A malfunctioning hub or bearing can lead to increased noise, vibration, and difficulty in steering the vehicle, impacting the vehicle's overall performance and safety.

Faulty wheel bearings can cause a significant amount of noise. This can be detected during the drive, and it is essential to address this issue promptly. Poorly maintained or damaged wheel hubs can also cause the wheels to wobble, causing an uncomfortable driving experience and potentially leading to a loss of control. Early detection and prompt maintenance are vital for maintaining safe driving conditions.

Inspecting wheel hubs and bearings for signs of damage or wear is a crucial aspect of preventative maintenance. This includes checking for abnormal noises, vibrations, or any visible damage to the hubs or surrounding components. Ignoring these signs can potentially lead to significant mechanical issues, making the repair process far more complex and costly in the long run.

Wheel Locks and Security

Wheel locks, while often overlooked, serve as a crucial security measure, deterring theft. Using appropriate wheel locks can significantly reduce the risk of your vehicle being stolen. Choosing high-quality, durable wheel locks that fit your specific vehicle type is important. Consider the locking mechanism's strength, design, and ease of use. Ensure the lock is secure and won't be easily bypassed. This will protect your investment and maintain the integrity of your vehicle.

Stealing car parts, including wheels, is a common crime in many urban areas. It is crucial to take measures to protect your vehicle. Investing in quality wheel locks can deter potential thieves and help to prevent your car from becoming a target. Adding security features to your vehicle is an important step toward ensuring the safety and security of your prized possession.

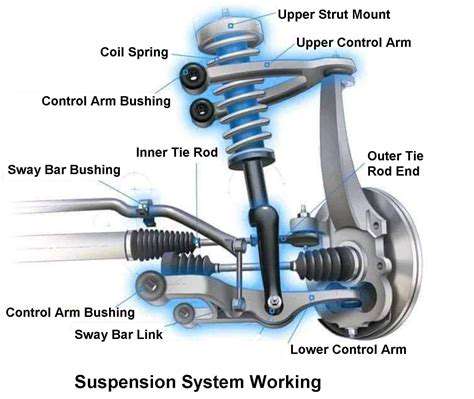

Analyzing Suspension Components

Understanding Shock Absorbers

Shock absorbers are crucial components of a vehicle's suspension system, playing a vital role in controlling the movement of the vehicle's springs and maintaining a stable ride. They absorb energy from bumps and impacts, converting kinetic energy into heat, reducing harsh jolts and vibrations felt by the occupants. This dampening effect significantly enhances passenger comfort and improves the vehicle's handling characteristics. Proper shock absorber function is essential for maintaining the integrity of the entire suspension system.

The design of shock absorbers varies depending on the vehicle's type and intended use. For example, high-performance vehicles often utilize specialized shock absorbers that are designed to offer both a smooth ride and impressive handling capabilities. Maintaining these components is equally vital as they require regular servicing to ensure optimal performance.

Inspecting Springs

Vehicle springs are critical components responsible for supporting the vehicle's weight and maintaining its ride height. They experience significant stress during normal driving, responding to road irregularities, and effectively storing and releasing energy to dampen the impact of these movements. This constant stress and strain necessitate careful inspection and maintenance to ensure their longevity and effectiveness. Spring failure can lead to catastrophic vehicle damage and a dangerous driving experience.

Different types of springs, such as coil springs, leaf springs, and torsion bars, have varying characteristics and capabilities. Recognizing these differences is critical for proper assessment and maintenance. Each type has specific stress limits and operational parameters that must be considered when conducting maintenance or replacement procedures.

Evaluating Stabilizer Links and Bushings

Stabilizer links and bushings are integral parts of the vehicle's suspension system, particularly vital for maintaining steering control and responsiveness. They connect the stabilizer bar to the vehicle frame, enabling the system to counteract the body's tendency to roll during turns or cornering. This component is essential for keeping the vehicle stable and preventing excessive body roll. The condition of these components significantly affects the vehicle's handling during high-speed maneuvers or tight turns.

Regular inspection of these components for wear and tear is crucial. Damage or excessive wear can lead to instability, reduced responsiveness, and a compromised driving experience. Maintaining these elements of the suspension system ensures stability and control in all driving conditions.

Assessing Control Arms and Ball Joints

Control arms and ball joints are fundamental components of the vehicle's steering and suspension, directly affecting the vehicle's handling and maneuverability. They connect the suspension system to the wheels, allowing the wheels to move up and down while maintaining the appropriate alignment for proper handling and steering. Any issues with these components can result in abnormal noises, steering difficulties, and poor handling.

Proper alignment and functioning of these components are paramount for a safe and controlled driving experience. Inspecting these components regularly for wear and tear or damage is crucial for maintaining overall suspension health. Ignoring these issues can escalate into significant issues, affecting the entire vehicle's stability and safety.

Considering the Role of Mechanical and Electrical Systems

Understanding the Interconnectedness

Mechanical and electrical systems are deeply intertwined in modern infrastructure, from skyscrapers to everyday appliances. Comprehending this interconnectedness is crucial to understanding their overall function and potential failure points. A malfunction in one system can cascade to the other, impacting performance and potentially leading to costly repairs and safety hazards. This interconnected nature necessitates a holistic approach to maintenance and design, ensuring both systems are considered simultaneously.

Properly integrating mechanical and electrical systems requires a deep understanding of the relationship between moving parts, power generation, and control mechanisms. For example, a faulty motor in a ventilation system not only reduces airflow but also can lead to electrical overload, causing a potential fire hazard. Recognizing these dependencies is vital for proactive maintenance and safety.

Optimizing Energy Efficiency

An essential consideration when dealing with mechanical and electrical systems is optimizing energy efficiency. Careful selection of energy-efficient motors, lighting systems, and control mechanisms can lead to substantial cost savings over time. Implementing smart technologies, such as programmable logic controllers (PLCs) and sensors, allows for real-time adjustments to energy consumption, reducing waste and improving overall operational efficiency. The use of renewable energy sources also plays an important part in optimizing the energy efficiency of these systems.

Minimizing energy consumption is paramount in modern society. Integrating sustainable practices during design and operation is key to reducing the environmental footprint of these systems. Retrofitting existing systems with more efficient components can yield significant cost and environmental benefits.

Ensuring Safety and Reliability

Safety is paramount when working with mechanical and electrical systems. Robust safety protocols, including proper grounding, circuit protection, and regular maintenance schedules, are critical to prevent accidents. Effective safety measures will mitigate potential risks that may otherwise lead to injuries or equipment damage. Identifying and mitigating potential hazards is an integral part of ensuring safe operation.

Maintaining the reliability of mechanical and electrical systems is vital for maintaining productivity and minimizing downtime. Regular preventative maintenance, including inspections and replacements of critical components, helps prevent breakdowns and ensures systems operate within their intended specifications. Robust diagnostics for early detection of potential problems also contributes to system reliability and longevity.

Addressing Maintenance and Repair

Efficient maintenance and repair strategies are critical for the long-term viability of mechanical and electrical systems. Developing comprehensive maintenance schedules that incorporate preventative measures, such as routine inspections, lubrication, and component replacements, is crucial for prolonging equipment lifespan and avoiding costly breakdowns. Proper maintenance protocols are key to minimizing downtime and preserving the integrity of these complex systems.

Implementing well-defined repair procedures minimizes the risk of causing further damage during troubleshooting. Utilizing standardized repair manuals and training technicians on proper procedures are essential components of a robust repair strategy. Proper diagnostics and documentation of repairs are necessary for tracking maintenance history and ensuring accountability. This proactive approach contributes to maintaining the structural integrity and functional viability of the entire system.

Impact on Building Design and Operation

The integration of mechanical and electrical systems significantly impacts the overall design and operation of structures. Modern building design increasingly emphasizes energy efficiency and sustainability, requiring sophisticated integration of these systems to meet these goals. Optimizing the placement and design of components is essential for effective operation, and this includes incorporating appropriate ventilation strategies and minimizing energy loss through insulation and sealing.

The management and operation of a building depend heavily on its mechanical and electrical systems. Efficient operation of HVAC systems, lighting, and security systems directly impacts occupant comfort and building performance. Understanding and managing these systems are crucial aspects of ensuring a successful and safe building operation.