HTML Element

CSS Class

HTML

Styling

Inspection

Industrial

CSS

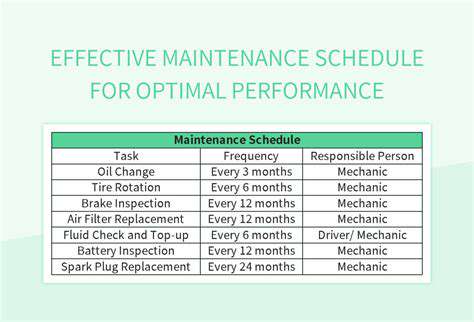

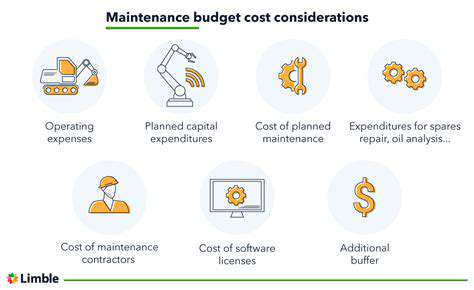

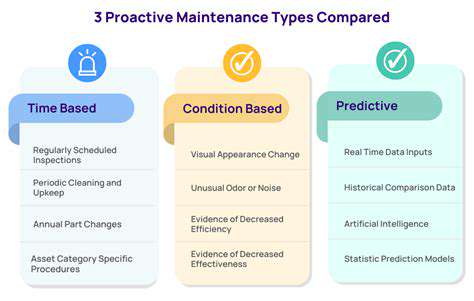

Maintenance

Troubleshooting

Endoskop: Prüfung schwer zugänglicher Bereiche

Effizienz und Sicherheit>

Wartung und Fehlerbehebung von Bohrschachtskopien

Vorbereitung der Wartung

Vor Beginn jeglicher Wartungs- oder Fehlerbehebungsmaßnahmen an einem Bohrschachtskop, ist eine sorgfältige Vorbereitung entscheidend. Dies beinhaltet das Sammeln der notwendigen Werkzeuge und

Read more about Endoskop: Prüfung schwer zugänglicher Bereiche

Sicherstellung der Verkehrssicherheit durch optimale Sicht und Wartung der WischerMeta-Beschreibung: Entdecken Sie die entscheidenden Faktoren, die die Sicht auf der Straße beeinflussen, einschließlich Wetter- und Fahrbedingungen. Erfahren Sie mehr über die entscheidende Rolle von Scheibenwischern, die verschiedenen Wischertypen, Wartungstipps und wie Sie optimale Sicht für sicherere Fahrerlebnisse unter allen Bedingungen gewährleisten können.Inhaltsübersicht: Dieser umfassende Leitfaden erklärt die Bedeutung von Sichtbarkeit auf der Straße und hebt hervor, wie Wetterbedingungen wie Regen, Nebel und Schnee die Fahrsicherheit beeinflussen. Er behandelt auch die entscheidende Rolle von Scheibenwischern für die Aufrechterhaltung einer klaren Sicht und erläutert die verschiedenen Arten von Wischern, ihre Mechanismen und die Bedeutung regelmäßiger Wartung. Gewinnen Sie Einblicke in Best Practices für die Wartung von Wischern, wie die Auswahl der richtigen Blätter, Reinigungstechniken und das Verständnis der Austauschfristen. Rüsten Sie sich mit dem Wissen aus, das Sie benötigen, um unabhängig von den Wetterbedingungen sicher zu navigieren.

Feb 25, 2025

Wartungsanforderungen für Sportwagen im Vergleich zu Familienlimousinen

Apr 29, 2025

Wichtigkeit regelmäßiger Inspektionen von Lenksystemkomponenten

May 02, 2025

Vorteile regelmäßiger Inspektionen der Antriebswellen-Ausrichtung

May 03, 2025

Warum regelmäßige Abgasanlagen-Inspektionen unerlässlich sind

May 06, 2025

Bewertung der Haltbarkeit moderner Hochleistungs-Bremsensysteme

May 11, 2025

Wie verbesserte Filterungssysteme die Luftqualität im Auto steigern

May 16, 2025

Häufige Ursachen für Überhitzung bei automatischen Getrieben

May 20, 2025

Ein umfassender Leitfaden zur essentiellen Rolle von Abgaskrümmern in Verbrennungsmotoren. Dieser Leitfaden untersucht die Grundlagen der Abgaskrümmer-Konstruktion und zeigt auf, wie diese die Effizienz steigern.

May 23, 2025

So lassen Sie die Bremsflüssigkeit Ihres Autos ab

Jul 13, 2025

Bremsflüssigkeits-Entlüftungskit: Bremsflüssigkeit entlüften

Jul 15, 2025