Bore Scope: Inspecting Hard to Reach Areas

Maintenance and Troubleshooting Bore Scopes

Preparing for Maintenance

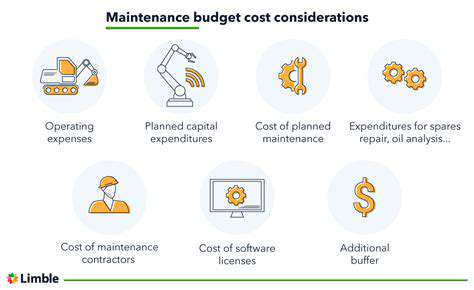

Before beginning any maintenance or troubleshooting procedures on a bore scope, meticulous preparation is key. This involves gathering necessary tools and supplies, such as cleaning solutions appropriate for the specific material the bore scope will be used on, protective gear like gloves and safety glasses, and a well-lit workspace. A thorough understanding of the bore scope's operational characteristics, including its power source and limitations, is also crucial. Improper handling or lack of preparation can lead to damage to the equipment or even personal injury.

Properly storing the bore scope is equally important. Storing it in a dry, cool environment, away from direct sunlight and extreme temperatures, will prolong the lifespan of the equipment. Ensuring the lens and other optical components are free from dust and debris is also a vital part of the preparation process. This proactive approach to maintenance significantly reduces the likelihood of encountering problems during operation.

Troubleshooting Common Issues

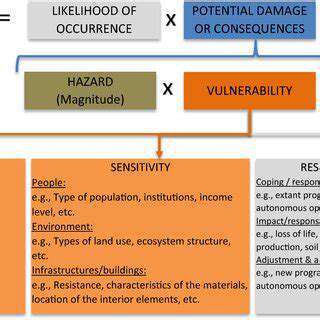

One of the most frequent challenges encountered during bore scope operation is image distortion. This can stem from various factors, including debris obstructing the lens, improper focusing, or even issues with the bore scope's internal components. Careful examination of the lens and focusing mechanism is necessary to identify the source of the problem. Addressing these issues through cleaning, recalibration, or replacement parts can restore clear and accurate imagery.

Another common problem is a lack of illumination. Insufficient light can obscure crucial details within the inspected area. Troubleshooting this issue involves verifying the power source and ensuring the light source is functioning correctly. If the light source itself is the problem, a replacement light source or a different lighting technique may be necessary to gain a clearer view of the area of interest. Using a variety of lighting techniques can greatly improve the quality of the inspection.

Cleaning and Disassembling the Bore Scope

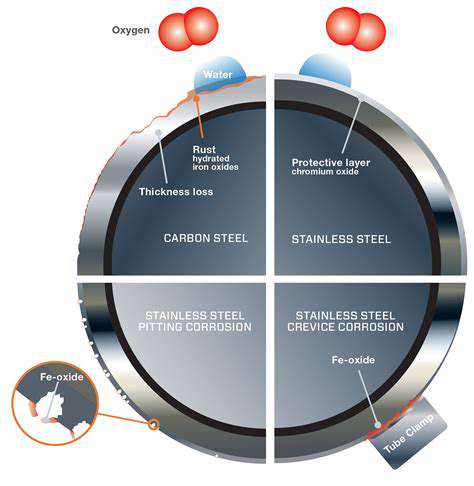

Regular cleaning is essential for maintaining the bore scope's functionality and longevity. This involves gently removing any debris or contaminants from the lens and other optical components. Use only appropriate cleaning solutions, avoiding harsh chemicals that could damage the delicate components. Thorough rinsing and drying are also essential steps to prevent residue build-up and ensure optimal performance.

Disassembling the bore scope for a more in-depth cleaning should only be performed by trained professionals. Improper disassembly can lead to damage to internal components and negatively affect the bore scope's overall performance and accuracy. Following the manufacturer's instructions precisely and seeking professional help when necessary is vital to maintaining the bore scope's integrity and extending its operational lifespan.

Maintaining Proper Functionality

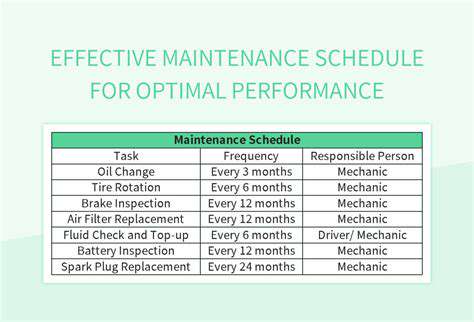

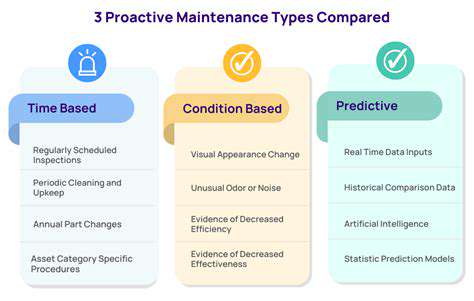

Maintaining proper functionality of a bore scope requires consistent monitoring of its performance. Regular checks of the bore scope's power source, lens clarity, and illumination are essential. This proactive approach can prevent minor issues from escalating into more significant problems. Keeping detailed records of maintenance activities and any observed anomalies can be invaluable for troubleshooting future issues.

Calibration is another crucial aspect of maintaining the bore scope's accuracy. Regular calibration, preferably by a qualified technician, ensures that the bore scope's measurements and images remain reliable and accurate. Investing in preventative maintenance and calibration can save time and money in the long run, preventing costly repairs and ensuring the bore scope remains a valuable tool for inspections.