Grasa dieléctrica: Protegiendo las conexiones eléctricas

Maintaining Electrical Connections with Dielectric Grease

Understanding the Importance of Dielectric Grease

Dielectric grease plays a crucial role in maintaining electrical connections, ensuring their reliability and longevity. It acts as an insulator, preventing electrical arcing and breakdown, especially in high-voltage applications. Proper application of dielectric grease significantly reduces the risk of short circuits and other electrical failures, leading to improved safety and operational efficiency. This insulation also protects the equipment from environmental factors such as moisture, dust, and temperature fluctuations.

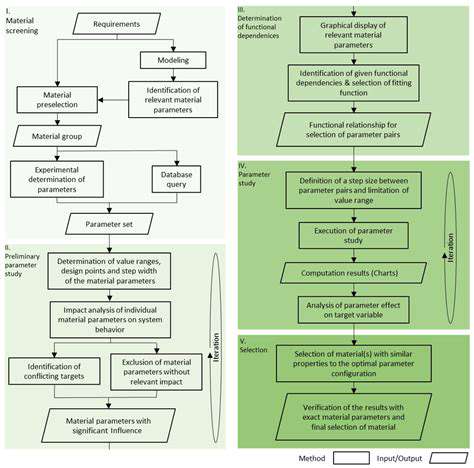

Types of Dielectric Greases and Their Applications

Various types of dielectric grease are available, each tailored for specific applications. Some are formulated for high-voltage environments, while others are designed for lower-voltage situations. The choice of grease depends heavily on the operating temperature, voltage levels, and the materials being insulated. Understanding the specific requirements of the application is essential to selecting the appropriate grease for optimal performance and safety.

Different types of electrical connections also require different types of dielectric grease. For example, high-frequency applications might call for a different formulation than those found in low-frequency systems.

Application Techniques for Effective Insulation

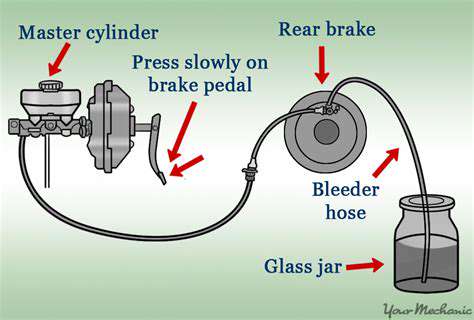

Proper application is key to achieving the intended benefits of dielectric grease. Apply a thin layer of grease, ensuring complete coverage of the connection points without creating excessive buildup. Avoid over-application, as this can lead to issues with heat dissipation and potentially affect the electrical properties of the grease. Using proper tools, like a grease applicator or a brush, is crucial for precise application.

Thorough cleaning of the connection points before applying the grease is equally important. This ensures good contact and prevents contaminants from interfering with the effectiveness of the grease.

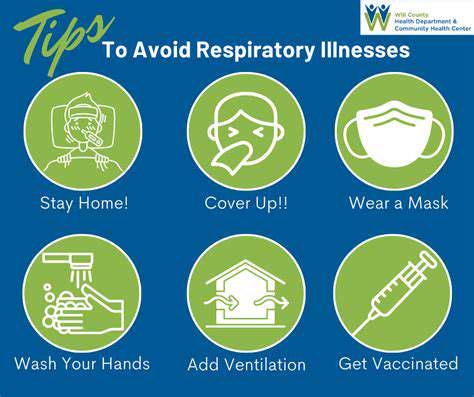

Protecting Against Environmental Factors

Dielectric grease acts as a barrier against environmental factors, such as moisture, humidity, and dust, which can negatively impact electrical connections. By forming a protective layer, it shields the connection points from corrosion and degradation. This is particularly important in environments with high humidity or exposure to harsh weather conditions.

The protection offered by dielectric grease is essential in preventing the formation of conductive pathways that could lead to electrical failures. In extreme conditions, this protection can be the difference between a reliable system and a catastrophic failure.

Troubleshooting Electrical Connections with Grease

If electrical connections are experiencing issues, such as arcing or overheating, carefully inspect the dielectric grease application. Check for any signs of damage, deterioration, or insufficient coverage. If necessary, remove the old grease and reapply a fresh layer following the recommended application procedures. Regular maintenance and inspections are vital to identify potential problems before they escalate into significant failures.

The Role of Dielectric Grease in Equipment Longevity

By effectively insulating electrical connections, dielectric grease contributes significantly to the longevity of the connected equipment. It protects components from corrosion, oxidation, and electrical breakdown, ultimately extending the lifespan of the equipment and reducing the need for costly repairs or replacements. The longevity aspect of using dielectric grease in electrical connections makes it a crucial part of proactive maintenance strategies.

Proper use and maintenance of dielectric grease can significantly extend the lifespan of electrical equipment, leading to substantial cost savings in the long run.