シャーシ補強:ハンドリング性能向上

車両強化のさまざまなアプローチ

トレーラー牽引安定性の向上のための専門家アドバイス。シャーシの補強は、車両性能向上の中心的な役割を果たします。さまざまな補強技術があり、それぞれが特定の車両要件に合わせて異なるメリットを提供します。

特殊な補強ソリューション

横方向支持システム

サイドマウントの補強部品は、特にボディロールの低減をターゲットにしています。これらのシステムは、ロングフレームメンバー間に強化された接続を作り、コーナーリングの安定性を大幅に向上させます。適切に設計された横方向の補強は、ボディの傾きを最大で~減少させることができます。

特殊なニーズのためのカスタム製作

工場出荷のソリューションを超えて、カスタム・ブレースは車両のダイナミクスを精密に調整することを可能にします。モータースポーツチームは、特定の重量配分とサスペンションのジオメトリを考慮したCAD設計部品を頻繁に採用しています。このレベルのカスタマイズは、測定可能なパフォーマンス向上をもたらすことがよくあります。

適切な補強ソリューションの選択

適切な補強を選択するには、複数の要因を慎重に検討する必要があります。

- 車両の重量配分パターン

- 想定される使用方法

- サスペンション構成

- パフォーマンスの期待値

サスペンション専門家への相談は、

ボディロール軽減技術

近代的な補強ソリューションは、より剛性の高い構造プラットフォームを作り出すことで、ボディロールを大幅に軽減します。この改善は、活発な運転中にすぐに実感できます。ボディの傾きが軽減されることで、より積極的なコーナリングが可能になります。シャーシの維持...

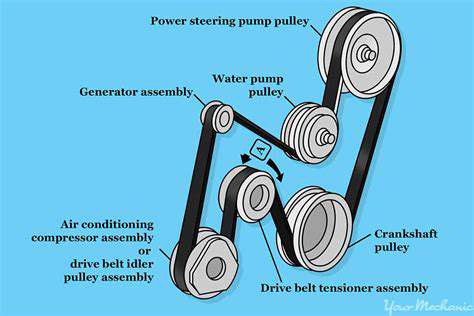

精密ステアリングの強化

補強により、ステアリング入力とホイールの反応が直接的に結び付きます。シャーシの撓みが軽減されることで、補強されていない車両にありがちなモッサリとした感触が解消され、瞬時のフィードバックが得られます。この改良は、緊急の操舵が必要な場面で、瞬時の反応が不可欠な状況で非常に価値あるものとなります。

サスペンションの相乗効果

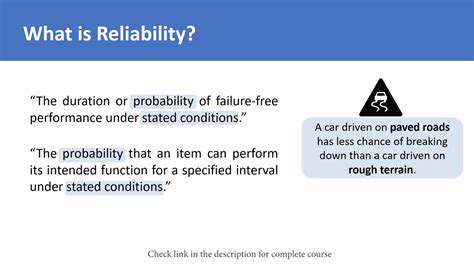

剛性の高いシャーシは、フレームの撓みに対抗することなく、サスペンション部品が設計通りに機能することを可能にします。この調和により、より一貫した減衰特性と優れた衝撃吸収性が得られます。特にオフロード車両は、この関係によって荒れた地形でも車輪の整列を維持できるため、この効果を大きく享受できます。

全体的な動的改善

適切な補強の累積効果は、車両の挙動を変えます。ドライバーは以下を経験します。

- 高速での安定性の向上

- コーナリング時の自信の向上

- より予測可能な重量移動

- 部品への機械的ストレスの軽減

騒音振動制御

性能上のメリットに加えて、補強はキャビンの騒音と振動を大幅に低減します。より剛性の高い構造により、車両内部に共振振動が伝わるのを防ぎ、より静かな室内環境を実現します。この改善は、快適性と認識される品質の両方を高めます。