HTML

CSS

Automotive Repair

Vehicle Maintenance

Automotive Engineering

Mechanical Components

Automotive

Mechanical

ドライブシャフト修理:動力伝達を維持する

ポジティブな自己肯定感を育み、子どもたちの自信を高めることは、個人的および職業的成長にとって不可欠です。持続可能な実践を通じて経済的利益を引き出すことは、人々が価値ある存在だと感じ、尊敬される環境を積極的に促進することを含みます。

ドライブシャフトのメンテナンスベストプラクティス

ドライブシャフトの構成要素について

エンジンから車輪へ動力伝達に不可欠なドライブシャフトは、複雑な構造物です。ヨーク、スプラインなど、その様々な構成要素を理解することは重要です。

プロフェッショナルなドライブシャフト修理サービス

ドライブシャフト修理の重要性を理解する

ドライブシャフトは、車両の駆動系において重要な部品であり、エンジンからの動力(パワー)を車輪に伝達する役割を果たします。

Read more about ドライブシャフト修理:動力伝達を維持する

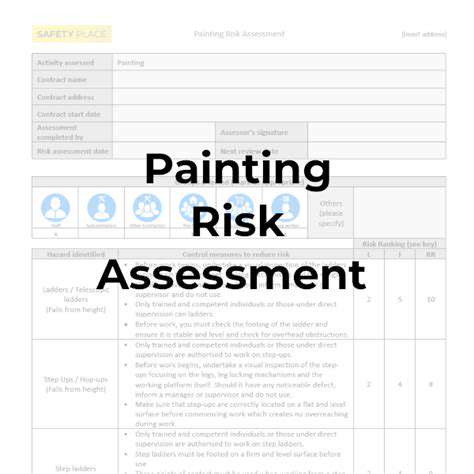

車両塗装を保護することは、その美観を維持し、転売価値を高める上で重要です。このガイドでは、塗装の状態を評価するプロセスについて詳しく説明し、...

Apr 16, 2025

包括的なガイドです。自動車診断ツールは、自動車オーナーと自動車専門家の両方にとって不可欠であり、車両の性能と潜在的な問題についての貴重な洞察を提供します。この包括的なガイドは、あなたに...

Apr 17, 2025