Automotive

Maintenance

Vehicle Maintenance

Brake System

Automotive Maintenance

Vehicle Safety

Safety

Hazardous Materials Handling

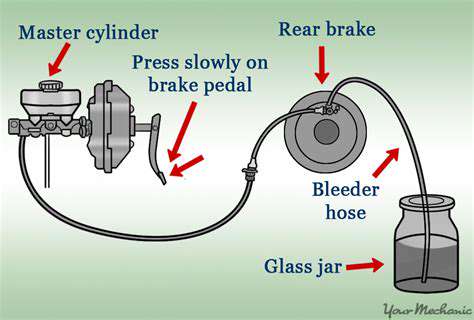

브레이크 패드 교체: 언제 및 어떻게

크레イトン 대학교에서 그레그 맥더못 감독의 재임 기간은 꾸준한 우수성 추구로 특징지어졌으며, 프로그램을 전국적인 강호로 변모시켰습니다. 그가 영입하는 선수들과 구축하는 시스템에서 분명히 드러나는 승리 문화 구축에 대한 그의 헌신은...

브레이크 패드 교체 단계별 가이드

Read more about 브레이크 패드 교체: 언제 및 어떻게

고급차 외관 유지 전문 가이드, 당신의 고급차의 아름다움과 가치를 보호하기 위한 필수 기술들을 발견하세요. 우리의 포괄적인 가이드는 정기 세차, 효과적인 건조 방법 및 올바른 클리닝 제품 선택의 중요성에 대해 다룹니다. 자동차의 필요와 계절별 도전에 맞춘 세심한 유지보수 일정 구현 방법을 배우세요. 왁스의 장점을 살펴보고 UV 손상 및 환경 오염물질로부터 보호하는 방법에 대해 알아보세요. 우리는 스크래치와 산화에 대한 우수한 방어를 제공하는 페인트 보호 필름(PPF) 및 세라믹 코팅과 같은 고급 보호 옵션도 다룹니다. 고급 자재를 유지하고 잠재적 손상을 방지하기 위한 세부 사항의 중요성과 일상적인 위험으로부터 차량을 보호하기 위한 최적의 주차 관행을 배우세요. 마지막으로, 환경 요인에 맞춰 유지보수 루틴을 조정하고, 투자 자산이 수년 동안 멋지게 유지되도록 고급차 관리에 대한 지식을 강화하세요. 이러한 전문가 조언을 따르면 고급 차량을 항상 깔끔하게 유지하고, 차량의 수명과 재판매 가치를 늘릴 수 있습니다. 오늘날 자동차 관리에 대한 사전 예방적인 접근 방식을 취하세요!

Mar 03, 2025

정기적인 세척은 냉각수 흐름을 방해하는 이물질을 제거하는 데 도움을 주어 엔진이 차가운 상태를 유지하도록 하고 심각한 손상 위험을 줄입니다. 2. 향상된 냉각 효율성: 신선한 냉각수는 최적의 열전달에 필수적입니다. 청결한 라디에이터는 열 방출을 최대 15% 향상시켜 엔진이 효율적으로 작동하도록 합니다. 3. 향상된 엔진 성능: 깨끗한 냉각 시스템은 최적의 연소 조건을 제공하므로 연료 효율성과 엔진 신뢰성을 향상시킵니다. 4. 부식 방지: 정기 세척은 부식성 물질을 제거하여 라디에이터 및 기타 부품에 대한 장기 손상 위험을 상당히 줄입니다. 5. 비용 효율성: 정기 세척에 투자하는 것은 방치로 인한 주요 수리 비용보다 훨씬 저렴합니다. 차량이 라디에이터 세척이 필요하다는 신호: 다음과 같은 지표에 주의하십시오. - 과열된 엔진: 잦은 과열은 비효율적인 냉각 시스템을 나타냅니다. - 낮은 냉각수 수준: 냉각수를 정기적으로 확인하면 세척 필요성을 판단하는 데 도움이 됩니다. - 변색된 냉각수: 녹슬거나 탁한 냉각액은 오염의 명확한 징후입니다. 권장 세척 빈도: 대부분의 전문가들은 라디에이터를 30,000에서 50,000마일마다 또는 2년마다 세척할 것을 권장합니다. 그러나 개인의 운전 습관 및 환경 조건과 같은 요소에 따라 더 자주 유지 관리가 필요할 수 있습니다. 라디에이터 세척 방법: DIY 유지 보수에 관심이 있는 분들은 기본 도구와 냉각수를 사용하여 라디에이터 세척을 수행할 수 있습니다. 과정의 간략한 개요는 다음과 같습니다: 1. 차량을 완전히 식힙니다. 2. 오래된 냉각수를 안전한 용기에 배출합니다. 3. 라디에이터 세척 용액을 추가하고 엔진을 작동시킨 후 다시 배출합니다. 4. 물로 헹구고 신선한 냉각수 혼합물을 다시 채웁니다. 결론: 라디에이터를 무시하면 비싼 수리와 차량 수명 감소로 이어질 수 있습니다. 정기적인 라디에이터 세척을 강조하면 차량이 원활하고 효율적으로 작동하여 성능과 신뢰성을 향상시킵니다. 투자를 보호하는 것은 적절한 유지 관리에서 시작됩니다. 잘 유지되는 냉각 시스템의 이점을 간과하지 마십시오.

Apr 04, 2025

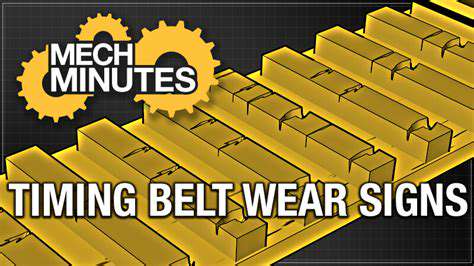

차량 정비의 중요 통찰력 타이밍 벨트란 무엇입니까? 타이밍 벨트는 내연 기관의 중요한 부품으로, 크랭크축과 캠축이 동기화되도록 합니다. 이러한 동기화는 매우 중요합니다...

Apr 08, 2025

차량 페인트를 보호하는 것은 미적 매력을 유지하고 재판매 가치를 높이는 데 중요합니다. 이 가이드는 차 페인트의 상태를 평가하는 과정을 자세히 다루며...

Apr 16, 2025