High-performance vehicles

Automotive engineering

Safety

Effectiveness

HTML

CSS

성능 브레이크 키트: 뛰어난 제동력

포괄적인 가이드

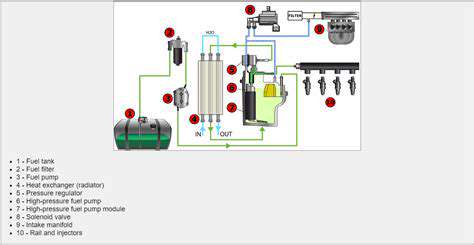

성능 브레이크 시스템 소개

Read more about 성능 브레이크 키트: 뛰어난 제동력

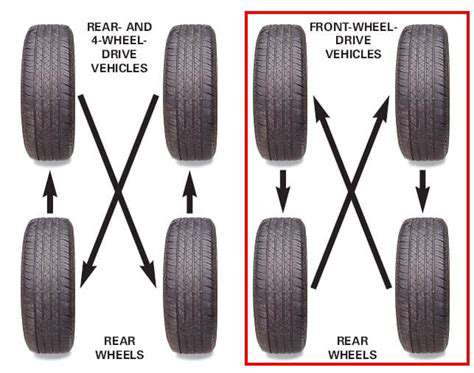

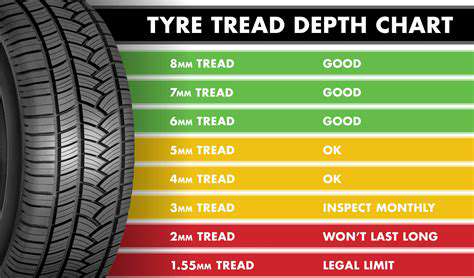

최적의 차량 성능을 위한 타이어 회전의 중요성 메타 설명: 정기적인 타이어 회전이 자동차의 내구성, 안전성 및 연료 효율성에 왜 중요한지 알아보세요. 타이어 마모 패턴, 경제적 장점, 타이어를 회전시키는 방법이 성능과 도로에서의 편안함에 어떻게 도움이 되는지 알아보세요. 콘텐츠 요약: 정기적인 타이어 회전은 차량 건강을 유지하는 데 필수적입니다. 다양한 타이어 마모 패턴을 이해하면 잠재적인 문제를 식별하고 적시에 회전을 계획하는 데 도움이 됩니다. 불균형한 마모는 차량의 성능과 안전성을 위협할 수 있으므로 정기적인 유지 관리가 매우 중요합니다. 타이어를 주기적으로 회전시킴으로써 수명을 연장하고 연료 효율성을 개선하며 전반적인 주행 안전성을 높일 수 있습니다. 잘 유지된 타이어는 접지력 손실과 제동 거리를 줄여 보다 부드럽고 안전한 주행을 제공합니다. 정기적인 회전은 교체 비용을 절감할 수 있는 경제적인 투자일 뿐만 아니라 제조업체 보증 조건을 준수할 수 있도록 보장합니다. 이 포괄적인 가이드에서는 타이어 회전의 이점에 대해 살펴보겠습니다. - 타이어 마모 패턴 이해하기 - 정기적인 회전의 경제적 장점 - 적절한 유지 관리를 통한 안전성 및 편안함 향상 - 타이어 회전이 차량 성능 및 내구성에 미치는 영향 타이어를 최상의 상태로 유지하여 경제적 및 생태적 이점을 누리는 방법을 알아보세요.

Nov 19, 2024

중요성, 이점 및 유지 관리.

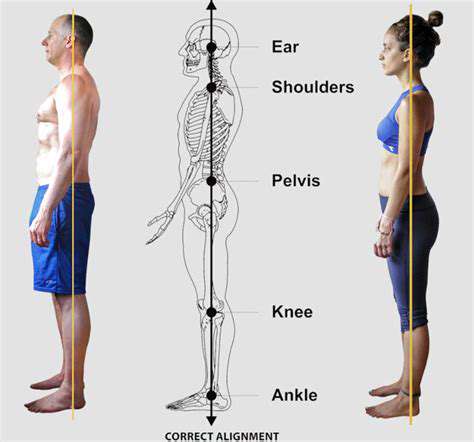

타이어 정렬은 차량 성능, 안전성 및 내구성에 필수적입니다. 이 웹페이지는 올바른 타이어 정렬을 유지하는 것의 중요성과 이것이 타이어 수명, 연료 효율성 및 전반적인 주행 안전성에 미치는 영향을 강조합니다. 차량이 정렬이 필요할 때의 징후를 알아보고 정기적인 정렬 점검의 비용 효과성을 확인하세요. 전방 및 추진 정렬을 포함한 다양한 유형의 정렬을 탐색하고 캐스터, 캠버 및 턴과 같은 요소들이 여러분의 주행 경험에 어떤 영향을 미치는지 이해하세요. 잘못된 정렬 징후를 인식하는 것을 포함하여 정기적인 유지 관리는 타이어의 수명을 크게 연장하고 보다 부드러운 주행을 보장할 수 있습니다.

비용이 많이 드는 수리를 피하고 주행 편안함을 높이기 위해 전문 서비스 및 정기 점검을 통해 차량 정렬을 우선시하세요. 이 페이지는 타이어 정렬과 차량 유지 관리에서의 중요 역할을 이해하는 포괄적인 가이드입니다.

Mar 05, 2025