HTML

Styling

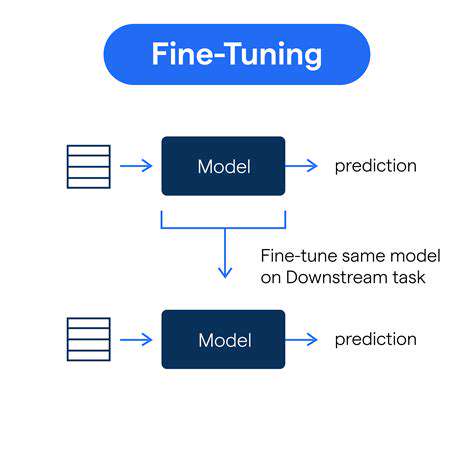

Turbocharging

Engine Performance

Turbocharger Performance

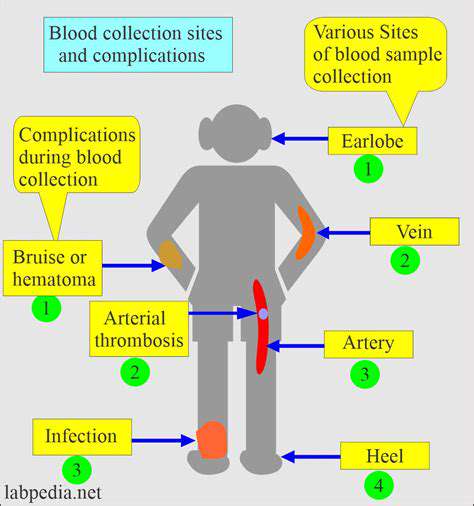

Engine Maintenance

배기 터보 샤프트 설치: 부스트 제어

단계별 웨이스트게이트 설치 가이드

필요한 도구 및 부품 준비

웨이스트게이트 설치 절차를 시작하기 전에 필요한 모든 도구를 확보하세요.

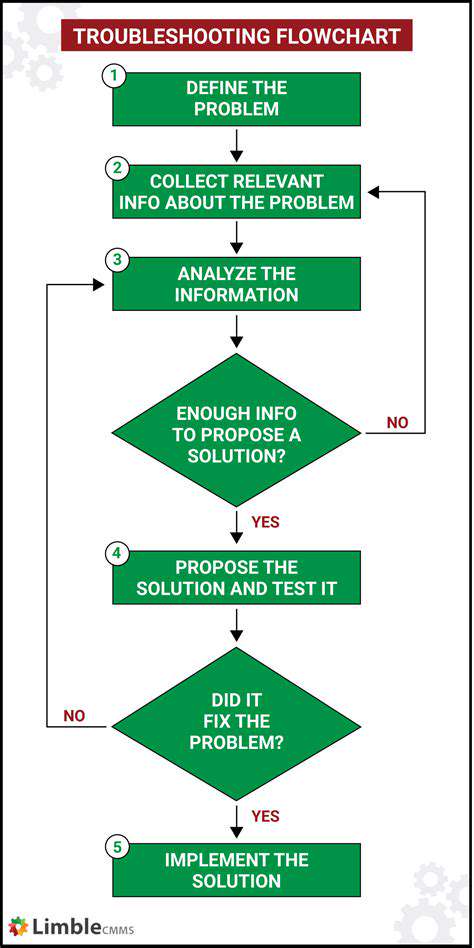

최적 성능을 위한 문제 해결 및 유지 관리

웨이스트게이트 설치 문제 및 해결책

적절한 웨이스트게이트 설치는 최적의 터보차저 성능과 엔진 수명에 중요합니다. 일반적인 문제는 웨이스트게이트의 잘못된 위치 조정을 포함합니다.