Pojazdy z ogniwami paliwowymi na wodór: Alternatywa

Membrana elektrolityczna jest kluczowym elementem ogniwa paliwowego, działając jako selektywna bariera. Pozwala na przechodzenie protonów, jednocześnie uniemożliwiając przepływ elektronów, utrzymując niezbędną separację elektryczną dla generowania prądu elektrycznego. Istnieją różne rodzaje membran elektrolitycznych,

Wyzwania i kwestie do rozważenia w zakresie wdrażania ogniw paliwowych na wodór

Rozwój infrastruktury

Jednym z głównych przeszkód w szerokim wdrożeniu ogniw paliwowych na wodór jest brak rozbudowanej i łatwo dostępnej infrastruktury wodorkowej. Obecnie sieci produkcji, magazynowania i dystrybucji wodoru są

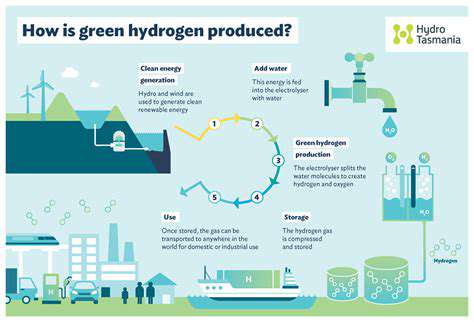

Metody produkcji wodoru i ich wpływ na środowisko

Elektroliza

Elektroliza to powszechnie znana metoda produkcji wodoru, wykorzystująca elektrolizę

Perspektywy przyszłości: Pojazdy z ogniwami paliwowymi wodorowymi w zmieniającym się krajobrazie motoryzacji

Rosnące zapotrzebowanie na zrównoważone transporty

Globalne dążenie do zrównoważonych rozwiązań transportowych przyspiesza, z wyraźnym naciskiem na redukcję emisji dwutlenku węgla. Ten trend napędza znaczne