Rolka osłonowa spawana: Maksymalna wytrzymałość

Quality Control and Inspection Procedures

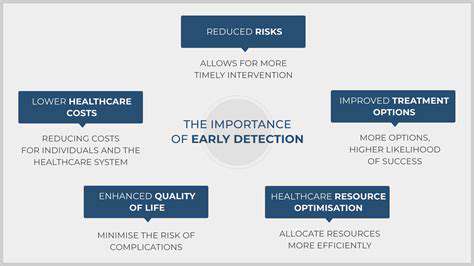

Importance of Quality Control

Quality control is a critical aspect of any manufacturing or production process. It ensures that products meet the required specifications and standards, which ultimately leads to customer satisfaction and brand loyalty. Implementing effective quality control procedures can significantly reduce defects and improve overall efficiency. This translates to lower costs associated with rework, repairs, and returns, ultimately boosting profitability.

By proactively identifying and correcting issues early in the production cycle, quality control minimizes the risk of delivering substandard products to customers. This proactive approach fosters a culture of quality, where every employee understands the importance of their role in maintaining high standards.

Inspection Techniques and Methods

Various inspection techniques are employed in quality control, depending on the specific product and industry. Visual inspections, often the initial stage, involve scrutinizing products for defects in appearance, dimensions, and overall functionality. This simple yet crucial step can prevent significant problems later in the production process.

Beyond visual inspections, more sophisticated techniques like dimensional measurements, material testing, and non-destructive testing are employed to assess the quality of materials and components. These methods provide a comprehensive evaluation of product characteristics, ensuring that they meet the specified requirements and standards.

Advanced technologies like automated optical inspection (AOI) systems are increasingly used to enhance efficiency and accuracy in identifying defects. These systems offer high-speed, precise, and consistent quality control, resulting in a significant reduction in human error and increased productivity.

Quality Control in Different Industries

Quality control principles are applicable across a wide spectrum of industries. In the automotive industry, meticulous quality control is essential to ensure the safety and reliability of vehicles. This is critical to prevent accidents and maintain consumer trust. Strict adherence to standards is paramount to minimize defects that could compromise the integrity and performance of the vehicle.

Similarly, in the food and beverage industry, quality control plays a crucial role in maintaining food safety and hygiene. Stringent inspections and testing procedures are implemented to ensure that products meet health standards and are free from contaminants. This is paramount to prevent foodborne illnesses and maintain consumer trust.

Quality control measures are also crucial in the pharmaceutical industry, where the safety and efficacy of drugs are paramount. Rigorous quality control procedures are employed throughout the production process to guarantee the purity, potency, and stability of medications.

The aerospace industry also prioritizes rigorous quality control to ensure the safety and reliability of aircraft components and systems. The consequences of defects in this industry can be severe, highlighting the vital role of quality control in ensuring airworthiness.

Implementing and Maintaining a Quality Control System

Establishing a robust quality control system involves more than just implementing inspection procedures. It requires a comprehensive approach that encompasses training, communication, and continuous improvement. Employees need to be adequately trained on the specific quality standards and inspection techniques to ensure consistent application. Effective communication channels are crucial for sharing information about defects, improvements, and best practices across all levels of the organization.

Furthermore, a quality control system requires ongoing monitoring and evaluation to identify areas for improvement. Regular audits, performance metrics, and feedback mechanisms help to identify weaknesses and optimize the system for maximum effectiveness. This continual refinement is essential to maintain a competitive edge and meet evolving industry standards.