Substituição do Evaporador do Ar Condicionado: Arrefecimento Interno

Understanding the AC Evaporator

The AC evaporator is a crucial component within your air conditioning system, responsible for absorbing heat from the air inside your vehicle. It does this by using a refrigerant that changes state from a gas to a liquid, absorbing the heat in the process. Understanding its function is key to understanding the importance of proper replacement when necessary.

A malfunctioning evaporator can lead to a variety of issues, from reduced cooling efficiency to complete system failure. Knowing what to look for, and when, is essential for maintaining a comfortable and efficient vehicle climate control system.

Identifying the Signs of a Failing Evaporator

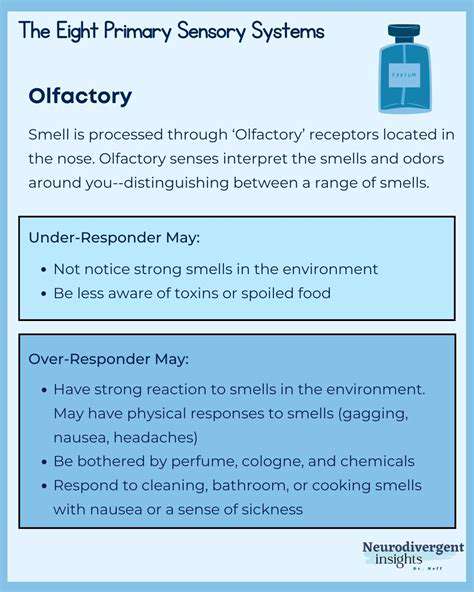

Recognizing the signs of a failing evaporator is essential for prompt action. Common symptoms include reduced airflow, a noticeable decrease in cooling power, unusual smells, or even strange noises emanating from the system. If you notice any of these, it's important to schedule a professional inspection to determine the root cause.

Gathering the Necessary Tools and Parts

Before beginning the replacement process, ensure you have the necessary tools and parts on hand. This includes the correct evaporator unit, appropriate refrigerant, specialized tools for handling refrigerants, and any necessary seals or gaskets. Having all the required parts readily available will prevent delays and ensure a smooth replacement process.

Thorough preparation and having the correct tools and parts are essential for a safe and effective replacement process.

Preparing Your Vehicle for the Replacement

Proper preparation is crucial for a safe and efficient replacement. This involves parking the vehicle on a level surface, disconnecting the battery, and ensuring the area is well-ventilated. These precautions help prevent accidents and ensure the safety of the technician and the vehicle itself.

Disconnecting and Removing the Old Evaporator

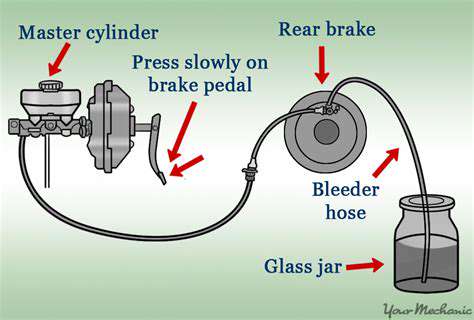

Carefully disconnect all electrical and refrigerant lines connected to the old evaporator. Follow the manufacturer's instructions carefully and take note of all connections and their locations for reassembly. Properly disconnecting and removing the old evaporator is vital to avoid damaging other components and ensuring a clean replacement.

This step is critical and should be performed with precision and care. Incorrect removal can lead to damage to other parts of the system.

Installing the New Evaporator Unit

Once the old evaporator is removed, carefully install the new unit, ensuring all connections are secure and properly sealed. Pay close attention to the orientation of the evaporator and make sure it's correctly aligned with the other components of the system. Correct installation is vital to ensure the new evaporator functions optimally.

Recharging and Testing the System

After the installation, recharge the system with the correct type and amount of refrigerant. This is a crucial step that should be performed by a trained technician to ensure the system operates safely and efficiently. Finally, thoroughly test the system to confirm that it's functioning correctly and providing the desired cooling capacity.

A professional inspection and testing after installation ensure the system operates at its peak efficiency.

Choosing the Right Replacement Evaporator Coil

Evaluating Your Needs

Before diving into the vast array of replacement EVA options available, it's crucial to assess your specific needs. Consider the intended use case for the EVA. Are you replacing a worn-out component in a specialized machine, or is this for a more general-purpose application? Understanding the context will significantly narrow down the viable choices and ensure you select a material that effectively meets your requirements.

Thorough evaluation of the existing EVA's performance and limitations is essential. Identifying weaknesses, such as susceptibility to wear, tear, or chemical degradation, will help you choose a replacement with enhanced properties. Consider factors like temperature resistance and chemical compatibility to ensure the new EVA can withstand the operating conditions.

Material Properties

Replacement EVA options vary significantly in their material properties. Understanding these differences is critical for selecting the right product. Different types of EVA exhibit varying degrees of flexibility, hardness, and resistance to various chemicals and environmental factors. Consider factors like tensile strength, elongation at break, and tear resistance when comparing options.

EVA's resistance to impact and abrasion is also a key consideration. Understanding the expected stresses and impacts on the replacement part will help you choose an EVA with the appropriate level of resilience and durability.

Cost Considerations

The cost of EVA replacement materials can range considerably depending on the specific type, quality, and quantity required. While cost is important, it should never be the sole determining factor. Balancing cost with the desired performance characteristics is crucial. A cheaper option might not provide the necessary durability or resistance to specific environmental factors, potentially leading to costly replacements in the near future.

Availability and Sourcing

Assessing the availability of the chosen EVA replacement material is critical. Reliable sourcing ensures timely procurement and minimizes disruptions to your operations. Research different suppliers and evaluate their lead times, quality control measures, and overall reputation to ensure a smooth and efficient procurement process.

Installation and Compatibility

The ease and safety of installing the replacement EVA is essential. Consider the specific installation procedures and any potential compatibility issues with existing components. Ensure the replacement EVA is compatible with the surrounding materials and will not cause any adverse reactions or degradation. Thorough research into the installation process will prevent costly errors or delays.

Environmental Impact

With growing environmental awareness, selecting a replacement EVA with a minimal ecological footprint is becoming increasingly important. Consider the material's recyclability and the overall environmental impact of its production and disposal. Choosing a sustainable EVA option can contribute to a more responsible and environmentally conscious approach to materials selection. Inquire about the supplier's commitment to sustainable practices and environmentally friendly manufacturing processes.