The operation of air bags in air suspension systems hinges on their design and integration with onboard sensors. When weight is applied, the air bags compress, and their internal pressure adjusts accordingly. This dynamic response mechanism allows for real-time adjustments to maintain ride height and comfort. Utilizing electronic control modules, modern air suspension systems can act almost instantaneously, enhancing both performance and safety.

Moreover, these air bags often have a lifespan that varies significantly depending on usage patterns. Frequent exposure to heavy loads or extreme temperatures can lead to premature wear. Therefore, monitoring is essential for longevity and effectiveness.

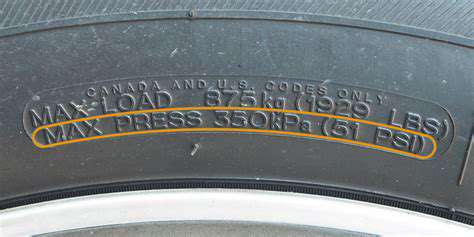

To ensure optimal performance, drivers should be aware of the specific air pressures recommended by manufacturers and routinely verify these levels. A well-maintained air suspension system can markedly improve vehicle handling, fuel efficiency, and overall comfort.

Signs of Air Bag Wear and When to Replace

- Visible cracks or tears in the air bag material

- Uneven ride height or sagging on one side of the vehicle

- Increased noise or vibration while driving

- Frequent warning lights related to suspension on the dashboard

- Oily residue around the air bags, indicating a leak

Identifying the need for Air Bag Replacement is crucial for maintaining vehicle safety and performance. Damage to air bags can manifest in various ways, including physical wear or mechanical failure. Visible signs such as cracks or uneven ride height should prompt immediate inspection.

Furthermore, the lifecycle of air bags is generally in the range of 50,000 to 100,000 miles. It's critical for vehicle owners to remain vigilant and consult their vehicle's manual for specific recommendations aimed at maximizing life expectancy.

Benefits of Air Suspension Systems with Air Bags

Switching to air suspension systems equipped with air bags can yield numerous advantages for both passenger comfort and vehicle performance. For instance, the ability to adjust ride firmness or softness based on load conditions enhances comfort during transport. Additionally, air suspension helps to significantly reduce vehicle maintenance costs over time due to better shock absorption and reduced wear on other suspension components.

Studies have shown that vehicles with air suspension have a notable improvement in handling characteristics, especially under load. According to the University of Michigan Transportation Research Institute, vehicles equipped with such systems experience a 20% increase in stability during cornering, making them invaluable for commercial applications.

In summary, the choice to utilize air suspension with air bags isn't just about comfort; it often translates into improved safety and reduced operational costs over the long haul. Therefore, for businesses or individuals that frequently transport heavy loads, the investment can be well worth it.

Signs That Your Air Bags Need Replacement

Understanding Air Bag Functionality

Air bags play a crucial role in enhancing Vehicle safety during collisions. They work in conjunction with other safety features, deploying within milliseconds upon impact to mitigate injury risk. A thorough understanding of how air bags function can help drivers recognize when there are issues that may necessitate replacement.

Modern air bags are equipped with sensors that detect sudden deceleration and impact forces. These sensors signal the air bag system to deploy, creating a protective cushion in front of passengers. The rapid deployment of the air bag is essential for effective protection, which is why maintaining their functionality should be a priority for any vehicle owner.

Warning Lights and Dashboard Indicators

One of the most immediate signs that your air bags may need replacement is the activation of warning lights on your dashboard. The air bag warning light typically indicates that there is a malfunction within the system, potentially affecting air bag deployment. Ignoring this signal can have serious implications for safety, making it imperative to investigate further.

In some vehicles, additional diagnostic codes can be accessed via an OBD-II scanner to pinpoint the specific issue. Keeping an eye on these indicators and addressing them promptly can save you time, money, and, ultimately, preserve your safety on the road.

Physical Damage to Air Bag Components

A physical inspection of the air bag components is vital for understanding their current condition. If you notice any visible signs of damage, such as tears or cracks in the air bag fabric, or corrosion on the electrical connectors, it is crucial to take action. Such physical defects can compromise the air bag's effectiveness and should not be overlooked.

Regular maintenance checks should include scrutiny of the air bag system, especially after accidents. Even minor collisions can damage components that may not be immediately apparent. Thus, if your vehicle has been in an accident, having the air bag system assessed by qualified technicians is critical to ensure your safety remains uncompromised.

Age and Expiration of Air Bags

Air bags, like many automotive components, have a lifespan that can be significantly affected by environmental factors and usage. Generally, it is recommended that air bags be inspected or potentially replaced after ten years of service. Over time, materials can degrade due to exposure to temperature extremes, humidity, and general wear.

While there is often a misconception that air bags do not expire, it is important to note that manufacturers set guidelines for replacement based on rigorous testing. Hence, even if the air bag appears to be intact, its internal mechanisms may not perform as intended due to age. To ensure maximum safety, consult your vehicle’s manual for specific recommendations regarding air bag maintenance and replacement intervals.

Professional Inspections and Recommendations

Engaging with a professional automotive technician for Regular Inspections is an effective way to ensure that your air bag system remains in optimal condition. Technicians have access to specialized diagnostic equipment that can identify potential problems that may not be visible during casual checks. Their expertise can guide you in making informed decisions regarding repairs or replacements based on industry standards.

In addition, technicians can provide valuable insights on recalls or manufacturer advisories pertaining to air bag systems. This proactive approach not only enhances safety but can also be a cost-effective measure in the long run. Following their recommendations can help prevent unforeseen incidents and ensure that your vehicle’s safety features function when you need them most.

The Air Bag Replacement Process

Understanding Air Bag Technologies

Air bags are critical components in vehicle safety, designed to deploy in the event of a collision. There are various types of air bags, including front, side, and curtain air bags, each serving a specific purpose. Front air bags, for example, protect the driver and front passenger, while side air bags provide additional protection during side-impact collisions.

In recent years, advancements in air bag technology have improved their effectiveness significantly. Modern air bags can now deploy at different speeds, depending on the severity of an impact, thanks to sophisticated sensors that assess collision dynamics. This adaptability ensures that the degree of protection is appropriate for each situation, reducing the risk of injury during accidents.

Assessing When to Replace Air Bags

Replacing air bags isn’t just about safety; it’s often a mandated requirement after a car has been involved in an accident where air bags deployed. Manufacturers typically specify guidelines for when replacement is necessary, suggesting that any activated air bag should be replaced immediately, even if the car appears to remain functional otherwise.

Additionally, it's essential to monitor warning lights on the dashboard. If the air bag light remains on, it indicates a malfunction, which could indicate that they may not deploy correctly in case of a further accident. Regular maintenance checks by certified technicians can help ensure your air bag system remains in optimal condition.

The Air Bag Replacement Procedure

The replacement process of air bags involves several steps to ensure complete safety and functionality. Initially, technicians will disconnect the vehicle's battery to prevent accidental deployment during the job. After that, they remove any necessary trim and components surrounding the defective air bag, which can vary widely by vehicle model.

Next, the old air bag is meticulously detached from the steering wheel or seat, depending on its location. Technicians must follow specific protocols to safely manage the air bag’s wiring harness and inflator system. Once the new air bag is secured, thorough testing of the entire SRS (Supplemental Restraint System) is conducted to ensure everything functions as intended before the vehicle is returned to service.

Finally, proper disposal of the old air bags is crucial, as they are classified as hazardous materials. The handling and disposal should comply with local regulations and environmental guidelines to mitigate any potential risks.

Cost Factors in Air Bag Replacement

Air bag replacement costs can vary significantly based on several factors, including vehicle make and model, labor rates, and the type of air bags being replaced. Typically, the cost for parts alone can range anywhere from $300 to over $1,500. This considerable variance often reflects differences in the complexity of repairs and the technology used in air bag systems.

Labor costs are also a significant factor, as experienced technicians are required to complete the job safely and correctly. Additionally, shops specializing in air bag repairs may charge a premium for their expertise. Consumers should gather multiple quotes and consider the reputation of the service center to ensure they receive quality work for their investment.

Choosing the Right Professionals for Air Bag Replacement

When it comes to air bag replacement, selecting a qualified technician is paramount. It’s advisable to seek out technicians with certifications from recognized organizations, such as ASE (Automotive Service Excellence) or manufacturer-specific training programs. These certifications indicate a commitment to maintaining up-to-date practices and knowledge in automotive safety systems.

Additionally, recommendations from friends, family, or online reviews can provide useful insights into a shop’s reliability and quality of service. Before committing, discussing the specifics of your vehicle’s needs and getting a detailed estimate can further prevent any surprises.

Ultimately, ensuring that the technician uses OEM (Original Equipment Manufacturer) parts can enhance the integrity and reliability of the air bag system. Although OEM parts may come with a higher price tag, they often provide better compatibility and performance compared to aftermarket alternatives.

Maintenance Tips for Air Suspension Systems

Regular Inspection and Diagnosis

One of the key aspects of maintaining an air suspension system is conducting regular inspections. These checks can help you identify any deformities or wear in components such as air springs, hoses, and compressors before they turn into bigger issues. Try scheduling bi-annual inspections for optimal performance; however, if you frequently drive on uneven terrain, consider doing it quarterly.

During the inspections, pay close attention to the compressor's function. If it’s constantly running or shows signs of overheating, it might be an indication of a failing part. Moreover, any visible air leaks from connections and fittings should be promptly addressed. Maintaining a checklist can streamline the inspection process, ensuring no details are overlooked and keeping your air suspension system running smoothly.

Proper Maintenance Practices

- Always use the manufacturer's recommended air pressure settings.

- Regularly check and clean the struts and air springs.

- Ensure that any brake line components do not interfere with the suspension system.

- Keep an eye on the electronic control system for errors or malfunctions.

In addition to inspections, implementing Proper Maintenance Practices can't be overlooked. Make sure to adhere strictly to the manufacturer's specifications for air pressure settings. This not only maximizes the performance of the air suspension system but also enhances overall safety. A study found that improper pressure can lead to premature wear on the components and reduced ride quality.

Another crucial aspect is to regularly check the struts and air springs for dirt or debris that may affect their performance. Even a small amount of contamination can lead to significant issues in the long run. Periodic cleaning and replacing damaged parts will help ensure a long-lasting functional air suspension system.