Gabinete de Jateamento: Limpeza de Peças

Introduction to Blast Cabinets and Their Importance in Cleaning Parts

Understanding Blast Cabinets

Blast cabinets, also known as abrasive blasting booths, are specialized enclosures designed for cleaning and surface preparation of various parts and components. These cabinets utilize a controlled environment to project abrasive materials at high velocity against the workpiece. This process effectively removes contaminants, rust, paint, and other undesirable surface imperfections. Understanding the key components and their functions within a blast cabinet is crucial for maximizing efficiency and safety during operation.

The primary function of a blast cabinet is to contain the abrasive blasting process, ensuring that the abrasive material is directed at the target part and not released into the surrounding environment. This containment is essential for worker safety and environmental protection, minimizing potential hazards associated with airborne abrasive particles.

Types of Blast Cabinets

Several types of blast cabinets exist, each tailored for specific applications and part sizes. Some common types include cabinet-style blast cabinets, which are suitable for smaller parts and components. These cabinets offer a compact design and are relatively easy to use. Other designs include tunnel blast cabinets, which are ideal for larger parts that need more extensive surface preparation. These units allow for continuous processing of items through the cabinet's length.

The choice of blast cabinet type depends significantly on the dimensions and quantities of parts to be cleaned, the required level of surface preparation, and the specific abrasive materials employed. Proper selection ensures optimal efficiency and safety.

Abrasive Materials Used in Blast Cabinets

A wide range of abrasive materials are available for use in blast cabinets, each with unique properties and applications. Common abrasives include steel grit, aluminum oxide, and silica sand. The selection of the appropriate abrasive is critical to achieving the desired surface finish and removing contaminants effectively while minimizing damage to the part being processed. Careful consideration must be given to the type of material being cleaned to ensure optimal results.

Different abrasives produce different surface finishes, and choosing the right one is crucial to the success of the blasting process. Understanding the characteristics of various abrasives enables the operator to select the most suitable material for each specific cleaning task.

Safety Considerations in Blast Cabinet Operation

Operating a blast cabinet requires strict adherence to safety protocols. Personal protective equipment (PPE), such as respirators, eye protection, and protective clothing, is essential to safeguard against the inhalation and contact of abrasive particles. Adequate ventilation systems within the cabinet are critical to maintaining a safe and healthy working environment, preventing the buildup of airborne contaminants. Proper training on safety procedures is paramount to minimize risks and promote responsible use.

Regular maintenance and inspection of the blast cabinet, including the ventilation system and abrasive containment mechanisms, are essential to ensure its safe and efficient operation. This preventative maintenance is critical to preventing accidents and maintaining the long-term functionality of the equipment.

Maintenance and Cleaning of Blast Cabinets

Regular maintenance is critical to the longevity and optimal performance of blast cabinets. This includes cleaning the abrasive collection system, checking for wear and tear on the blasting equipment, and ensuring that the ventilation system is functioning correctly. Maintaining the cabinet's integrity is important to ensure that the blasting process continues to operate safely and effectively. The frequency of maintenance depends on the intensity of use and the type of abrasive material used.

Proper cleaning of the blast cabinet's interior and surrounding areas is essential to prevent the buildup of abrasive dust and debris. This not only maintains the cleanliness of the work area but also contributes to the longevity and efficiency of the blasting equipment. Regular cleaning helps to prevent the accumulation of abrasive particles, which can pose a health hazard to operators and potentially damage the equipment over time.

Applications of Blast Cabinets in Various Industries

Blast cabinets find applications in a wide range of industries, including manufacturing, automotive, construction, and aerospace. In the manufacturing sector, they are used for cleaning metal parts, preparing surfaces for painting, and removing rust. In the automotive industry, blast cabinets are employed to clean components for assembly and maintenance. In the construction sector, they aid in surface preparation for concrete and metal structures. The versatility of blast cabinets makes them a valuable asset across many industries requiring surface preparation.

Blast cabinets are essential for preparing surfaces for various processes, including painting, coating, and welding. They enable the removal of contaminants and imperfections, ensuring a suitable surface for subsequent applications. This contributes to improved quality control, reduced defects, and enhanced product longevity.

Safety Considerations in Blast Cabinet Operation

Blast Cab Operator Training

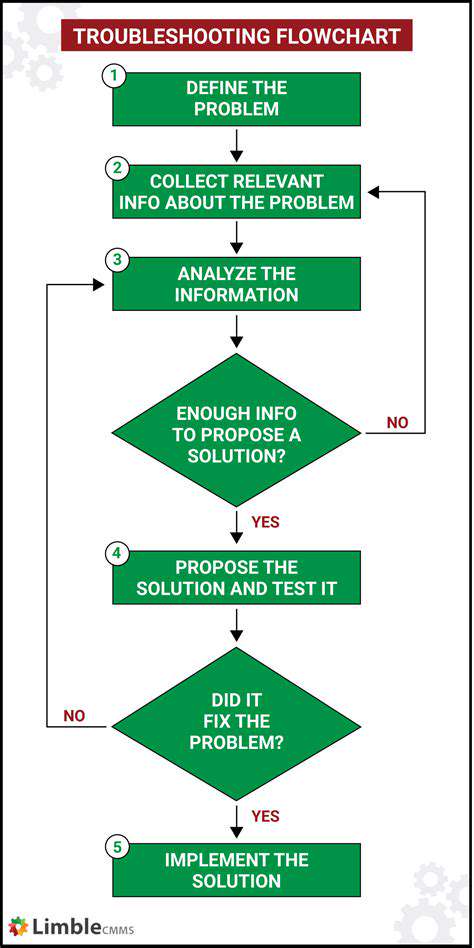

Comprehensive operator training is crucial for ensuring safe and efficient operation of a blast cab. This training should cover all aspects of the equipment, including proper procedures for pre-blast inspections, equipment operation, and emergency response protocols. Operators must understand the potential hazards associated with the operation and how to mitigate these risks. This includes understanding the limitations of the equipment and the importance of adhering to safety regulations and guidelines.

Training should also emphasize the importance of recognizing and reporting any malfunction or potential hazard. A thorough understanding of the equipment's capabilities and limitations is essential to prevent accidents. Regular refresher courses should be provided to maintain and update the operators' knowledge and skills.

Equipment Maintenance and Inspection

Routine maintenance and thorough inspections are vital to the safe operation of a blast cab. This includes checking for any signs of wear and tear, damage, or malfunction in all components, including hydraulics, electrical systems, and safety mechanisms. Ensuring the equipment is in optimal working condition is paramount to preventing accidents. Regular maintenance schedules should be strictly adhered to, and any necessary repairs should be promptly addressed by qualified technicians.

Detailed records of all maintenance and inspection activities should be meticulously kept. These records provide a valuable historical reference for identifying potential trends, predicting maintenance needs, and ensuring ongoing compliance with safety regulations.

Emergency Procedures and Response

Developing and practicing emergency procedures is critical for minimizing the impact of unforeseen events within a blast cab operation. This includes procedures for responding to equipment malfunctions, fire hazards, and potential injuries. Clear communication protocols must be established and practiced regularly. Operators must be familiar with the location and operation of emergency shut-off valves and other safety equipment.

Training should also include drills simulating various emergency scenarios. Regular drills and exercises will help operators become proficient in responding to emergencies, minimizing risks, and ensuring the safety of personnel and equipment involved in the blast cab operation.

Environmental Considerations

Blast cab operations often take place in challenging environments, and consideration must be given to potential environmental impacts. This includes factors such as dust control, noise pollution, and the proper disposal of hazardous materials. Operators should be adequately trained to minimize environmental damage associated with their work.

Compliance with environmental regulations and guidelines is crucial. Environmental protection is a critical part of any responsible blast cab operation. Employing dust suppression techniques, using noise-reducing equipment, and proper waste management procedures are essential for preserving the local environment while maximizing safety.