Instalação de Kit Bluetooth para Carro: Condução Livre de Mãos

Before any installation process begins, meticulous vehicle preparation is paramount. This involves a thorough inspection of the entire area where the installation will occur. Identifying potential obstacles or challenges, such as hidden wiring or structural elements, is essential for a smooth and successful installation. Failing to adequately prepare the vehicle can lead to significant complications and delays down the line.

Carefully document any existing modifications or features that may impact the installation. This detailed record-keeping will prove invaluable during the installation process and serve as a reference point for troubleshooting or adjustments as needed.

Surface Assessment and Cleaning

A clean and clear installation area is critical for a professional-looking and lasting installation. This encompasses thorough cleaning of the chosen surface, removing any dirt, debris, or residue that could compromise the adhesive or mounting system. Careful attention to detail during this stage significantly enhances the longevity and aesthetics of the finished product.

Ensuring the surface is completely dry and free from any contaminants is vital for achieving a strong and reliable bond. Improper surface preparation can lead to a poor installation and potential future issues.

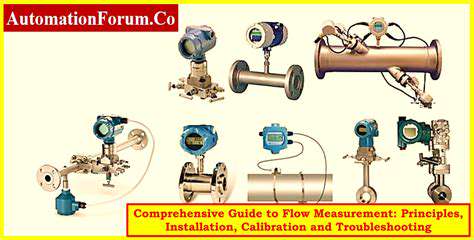

Wiring and Component Evaluation

Evaluating the existing wiring and components in the vehicle is crucial for a safe and effective installation. This evaluation process will identify any necessary modifications, additions, or replacements to ensure optimal performance and safety. Inspecting existing connections, ensuring sufficient power, and verifying correct signal routing are all vital steps.

Potential modifications or additions will need to be carefully considered during this stage. This might include the addition of new wiring, connectors, or even the replacement of existing components to facilitate a seamless and safe connection.

Tools and Materials Inventory

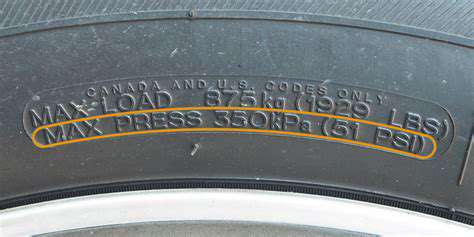

A well-stocked toolkit is essential for a successful installation. Ensure you have all necessary tools and materials on hand, including specialty tools, fasteners, and any additional components required for the installation. A thorough inventory of tools and materials will prevent unnecessary delays and ensure a smooth workflow during the installation process.

This includes checking the availability of appropriate fasteners, adhesives, and any specialized components. Having a complete list and readily available supplies is crucial to a successful project completion.

Environmental Considerations

Proper environmental conditions are essential to prevent damage to components and ensure a clean and safe installation. Maintaining a controlled temperature and humidity level, and avoiding direct sunlight or moisture, is crucial for the quality of the work. The environment can significantly impact the success of the installation and potentially cause future problems.

Consider the ambient temperature and humidity levels during the installation process. Extreme conditions can negatively affect the adhesive properties or the performance of components, leading to a less durable installation.

Safety Protocols

Adhering to strict safety protocols is paramount to avoid accidents or injuries during the installation. This includes properly handling tools, using appropriate protective gear, and working in a well-ventilated area. Following established safety procedures is essential for a secure and safe working environment.

Ensuring proper grounding and electrical safety measures are taken throughout the process is vital. Failure to comply with these safety protocols can have serious consequences and should be avoided at all costs.

Documentation and Record Keeping

Thorough documentation of the installation process is vital. This includes detailed records of steps taken, measurements, and any modifications made during the installation. This documentation is critical for troubleshooting, future maintenance, or any necessary adjustments that may need to be made at a later date.

Keeping a detailed log of every step and any adjustments made will provide valuable insight and support should any issues arise in the future. This detailed documentation will be invaluable for ensuring the longevity and reliability of the installation.

Data interoperability, the ability of different systems to exchange and use data seamlessly, is a significant challenge in modern data management. Different systems often use disparate formats, structures, and vocabularies, making it difficult to integrate data from various sources. This lack of compatibility can lead to wasted resources and hinder the ability to derive meaningful insights from the combined data.