Automotive

Maintenance

Vehicle Maintenance

Brake System

Automotive Maintenance

Vehicle Safety

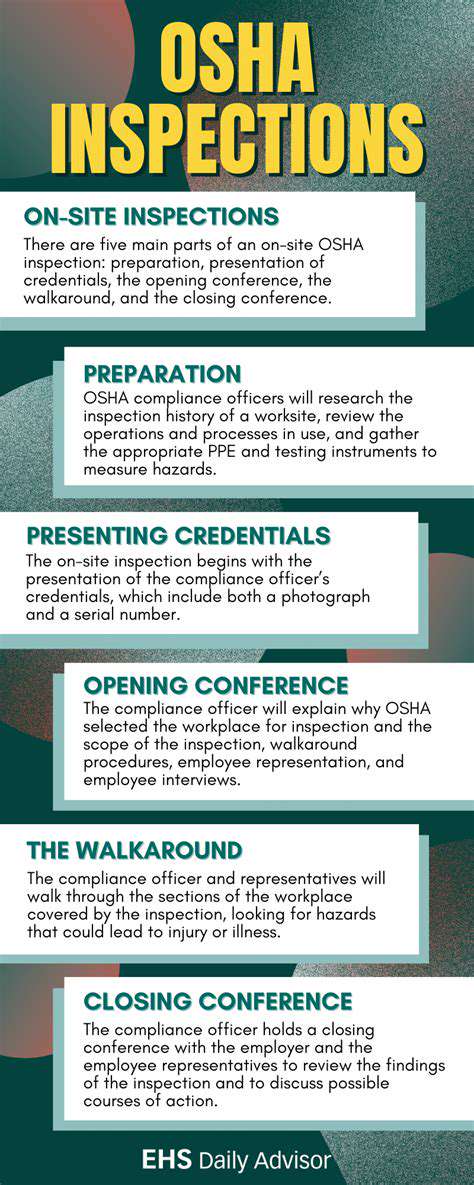

Safety

Hazardous Materials Handling

Substituição de Pastilhas de Freio: Quando e Como

O mandato de Greg McDermott na Creighton tem sido marcado por uma busca consistente pela excelência, transformando o programa numa potência nacional. Este compromisso em construir uma cultura vencedora, evidente nos jogadores que recruta e nos sistemas

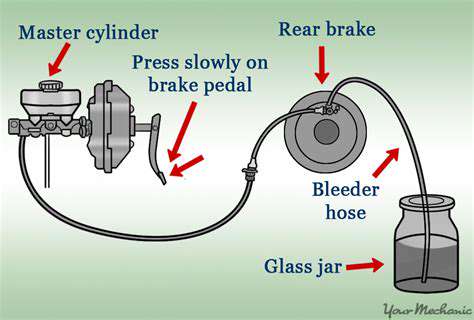

O Processo Passo a Passo de Substituição de Pastilhas de Freio

Compreendendo a Importância da Substituição de Pastilhas de Freio

A substituição regular das pastilhas de freio é crucial para manter a segurança e o desempenho do veículo. As pastilhas de freio, como

Precauções e Considerações de Segurança

Read more about Substituição de Pastilhas de Freio: Quando e Como

Guia especializado para manter o acabamento de carros de luxo. Descubra técnicas essenciais para preservar a beleza e o valor do seu carro de luxo. Nosso guia completo aborda a importância da lavagem regular, métodos de secagem eficazes e a escolha dos produtos de limpeza adequados. Aprenda como implementar um cronograma de manutenção meticuloso adaptado às necessidades do seu carro e aos desafios sazonais que você enfrenta. Explore as vantagens da cera e como ela protege contra danos causados por raios UV e contaminantes ambientais. Também abordamos opções de proteção avançadas, como Película de Proteção de Pintura (PPF) e revestimentos cerâmicos, que oferecem defesas superiores contra arranhões e oxidação. Aprenda a importância da detalhamento na manutenção de materiais de alta qualidade e na prevenção de danos potenciais, assim como as melhores práticas de estacionamento que protegem seu veículo de perigos cotidianos. Por fim, adapte sua rotina de manutenção a fatores ambientais e eduque-se sobre cuidados com carros de luxo para garantir que seu investimento permaneça deslumbrante por muitos anos. Ao seguir essas dicas de especialistas, você manterá seu veículo de luxo com aparência impecável, prolongando sua vida útil e valor de revenda. Abrace uma abordagem proativa para os cuidados com o seu carro hoje!

Mar 03, 2025

Limpezas regulares ajudam a remover detritos que podem obstruir o fluxo de refrigerante, garantindo que seu motor fique frio e reduzindo a chance de danos graves. 2. Eficiência de Resfriamento Melhorada: Refrigerante fresco é essencial para a transferência de calor ideal. Um radiador limpo pode aumentar a dissipação de calor em até 15%, garantindo que seu motor funcione de forma eficiente. 3. Desempenho do Motor Aprimorado: Um sistema de resfriamento limpo resulta em melhor economia de combustível e um motor mais confiável, pois permite condições de combustão ideais. 4. Prevenção de Corrosão: A limpeza rotineira remove substâncias corrosivas, minimizando significativamente o risco de danos a longo prazo ao radiador e a outros componentes. 5. Custo-Benefício: Investir em limpezas regulares é muito mais barato do que os custos associados a grandes reparos devido à negligência. Sinais de que seu Veículo Precisa de uma Limpeza do Radiador: Fique atento aos seguintes indicadores que sinalizam que é hora de fazer uma limpeza no radiador: - Motor Superaquecido: O superaquecimento frequente sugere um sistema de resfriamento ineficaz. - Níveis Baixos de Refrigerante: Verificar regularmente seu refrigerante pode ajudar a determinar a necessidade de uma limpeza. - Refrigerante Descolorido: Refrigerante enferrujado ou turvo é um claro sinal de contaminação. Frequência Recomendada para Limpezas do Radiador: A maioria dos especialistas recomenda limpar o radiador a cada 30.000 a 50.000 milhas ou a cada dois anos. No entanto, fatores individuais, como hábitos de direção e condições ambientais, podem exigir uma manutenção mais frequente. Como Fazer uma Limpeza do Radiador: Para quem está interessado em manutenção DIY, uma limpeza do radiador pode ser realizada com ferramentas básicas e refrigerante. Aqui está uma breve visão geral do processo: 1. Deixe o seu veículo esfriar completamente. 2. Drene o refrigerante antigo para um recipiente seguro. 3. Adicione uma solução de limpeza do radiador, ligue o motor e depois drene novamente. 4. Enxágue com água e preencha com uma mistura de refrigerante fresca. Conclusão: Ignorar o radiador pode levar a reparos caros e diminuir a longevidade do veículo. Enfatizar limpezas regulares do radiador garante que seu veículo funcione de forma suave e eficiente, melhorando o desempenho e a confiabilidade. Proteger seu investimento começa com a manutenção adequada; não ignore os benefícios de um sistema de resfriamento bem mantido.

Apr 04, 2025

Perspectivas essenciais para a manutenção de veículos O que é uma correia dentada? Uma correia dentada é um componente crítico de um motor de combustão interna que garante que o virabrequim e o eixo de comando girem em sincronia. Esta sincronização é...

Apr 08, 2025

Um Guia CompletoProteger a pintura do seu veículo é crucial para manter seu apelo estético e aumentar seu valor de revenda. Este guia aprofunda no processo de avaliar a condição da sua pintura, utilizando...

Apr 16, 2025

Manutenção do alinhamento adequado dos componentes da transmissão

May 01, 2025

Benefícios da integração de ferramentas de monitoramento em tempo real para manutenção de automóveis

May 02, 2025

Diferenças entre a manutenção de freios de tambor e de disco

May 02, 2025

Analisando padrões de desgaste nas pastilhas de freio para melhor manutenção

May 06, 2025

Conselhos de especialistas sobre a manutenção de carrocerias de automóveis resistentes à corrosão

May 16, 2025

Dicas de cuidados com os pneus: Melhorando a aderência e a eficiência de combustível

Jun 07, 2025

Kits de Freios de Desempenho: Potência de Frenagem Superior

Jun 27, 2025

Nitrogênio nos Pneus: Benefícios Explicados

Jul 02, 2025