Understanding the Different Types of Gasket Materials

Gasket sealants come in various materials, including rubber, silicone, and fiber. Each type is designed for specific applications and environments, making it crucial to select the appropriate material. The choice can affect the longevity and effectiveness of the sealant, particularly under high-pressure or temperature conditions.

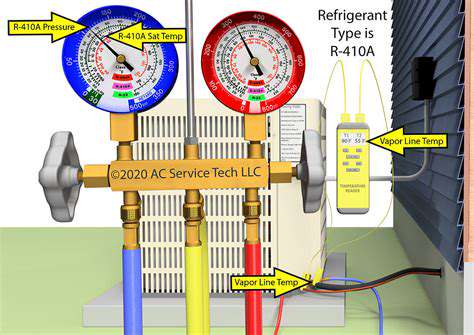

For example, rubber gaskets are often used in plumbing applications due to their excellent sealing capabilities and resistance to water. Silicone gaskets, on the other hand, are preferred in automotive and HVAC systems because of their versatility and resilience to heat and chemicals.

Choosing Between Liquid and Pre-formed Gasket Sealants

When considering gasket sealants, you may encounter liquid and pre-formed options. Liquid sealants usually come in tubes and can fill irregular spaces effectively, making them ideal for complex shapes. On the flip side, pre-formed gaskets offer ease of use and consistent thickness, ideal for precise applications.

Liquid sealants may require additional curing time, while pre-formed gaskets provide immediate sealing capabilities. Understanding the specific needs of your project will guide you in making the right choice between these two forms.

The Importance of Temperature and Chemical Resistance

Temperature and chemical resistance are critical factors to consider when selecting a gasket sealant. Different environments may expose sealants to varying temperatures and corrosive substances. High-temperature silicone sealants, for example, can withstand temperatures up to 500°F, making them suitable for engine components.

Moreover, chemical resistance is vital in industrial applications where exposure to solvents or acids is common. Many manufacturers provide detailed specifications on the chemical compatibilities of their products, which should be reviewed before making a selection.

Application Methods for Gasket Sealants

Application methods vary significantly based on the type of gasket material. Liquid sealants usually require a brush or nozzle for even distribution, while pre-formed gaskets can often be installed by hand. Some may benefit from the assistance of specific tools to ensure the proper fit and effectiveness of the seal.

Additionally, proper surface preparation is essential. Cleaning and degreasing the surfaces remove contaminants that could affect adhesion. Understanding how to effectively apply gasket sealants ensures a reliable seal and prolongs the life of the assembly.

Evaluating Performance and Longevity

The performance and expected longevity of gasket sealants depend on several factors, including application, environment, and material. Always consult manufacturer guidelines for performance expectations, as some sealants come with warranties, indicating their anticipated lifespan when used correctly.

Testing your chosen sealant under real-world conditions can also provide insights into how well it will perform over time. Pay attention to any signs of wear, leakage, or degradation, as these can be early indicators of a failing seal that needs addressing.

Expert Tips for Successful Gasket Sealing

To achieve optimal results with gasket sealants, some expert tips can be invaluable. Always follow the recommended curing times specified by manufacturers for best results. Additionally, avoid overtightening bolts and screws, as this can compress the gasket too much and lead to premature failure.

Experience has shown that investing time in thorough surface preparation pays off significantly. Abrading or sanding to create a better bonding surface often yields superior performance. A well-informed, meticulous approach contributes greatly to the success of sealing applications.

Applications of Gasket Sealants in Various Industries

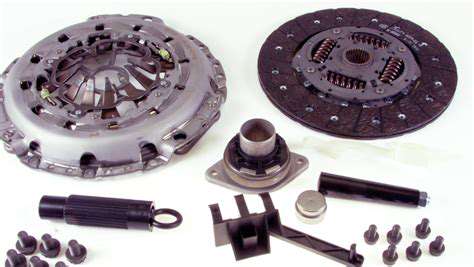

1. Automotive Industry Applications

Gasket sealants are prevalent in the automotive sector, where they serve multiple functions. They are engineered to withstand extreme temperatures and pressures, ensuring reliable sealing of engine components. Typical applications include sealing engine blocks, oil pans, and transmission housings, where preventing leaks is crucial for performance and safety.

Moreover, the compatibility of gasket sealants with various automotive fluids enhances their overall functionality. With vehicles becoming more complex, integrating advanced materials into gasket design improves lifespan and efficiency. Utilizing high-quality sealants can significantly reduce maintenance costs by minimizing leakage-related repairs.

2. Aerospace Engineering Considerations

The aerospace industry demands the utmost precision and reliability; thus, gasket sealants play a critical role in various applications. In aircraft manufacturing, the use of aerospace-grade sealants ensures that components remain leak-free under fluctuating atmospheric conditions. Sealants are found in fuel systems, hydraulic systems, and airframe structures, where they must perform flawlessly to maintain safety and performance standards.

- The ability of gasket sealants to withstand significant variations in temperature and pressure is crucial.

- Adhering to precise industry standards, such as those outlined by the FAA, ensures compliance and safety.

- Some modern sealants even incorporate features that allow for easier disassembly of components without compromising effectiveness.

3. Industrial Manufacturing and Machinery

In industrial manufacturing, gasket sealants are indispensable for maintaining efficiency in machinery and equipment. They prevent fluid and gas leaks, which can lead to costly downtimes and operational inefficiencies. For example, applications in pumps, compressors, and piping systems demonstrate how effective sealants can enhance overall reliability.

Furthermore, with industries becoming more conscious of sustainability, using biodegradable and environmentally friendly sealants is gaining traction. This shift not only addresses regulatory compliance issues but also aligns with corporate social responsibility goals. Companies seeking to improve their environmental footprint should consider these alternatives, as the benefits extend beyond compliance to brand value and consumer trust.

Benefits of Using Gasket Sealants for Leak Prevention

Enhanced Durability of Seals

Using gasket sealants significantly increases the Longevity of Seals by providing robust protection against environmental factors. This durability is crucial, especially in applications exposed to extreme temperatures and pressure fluctuations. Studies show that properly applied sealants can extend the lifespan of gasketed joints by up to 30%.

Additionally, these sealants can resist degradation from chemicals and oils, which would otherwise compromise the integrity of traditional gasket materials. For industries like automotive and manufacturing, selecting high-quality gasket sealants is an important consideration for maintaining equipment efficiency.

Cost-Effectiveness in the Long Run

While there might be an initial investment in gasket sealants, the overall cost savings are substantial over time. Preventing leaks not only saves on repairs but also minimizes downtime, which can be costly for businesses. For example, implementing sealants in automotive applications can reduce engine maintenance costs significantly, as a well-sealed engine operates smoother and requires less frequent servicing.

Improved Performance Under Pressure

- Sealants provide a tighter bond than traditional gaskets.

- They can withstand higher internal pressures without failure.

Sealants are engineered to maintain their structural integrity under high pressure situations, which is essential in industries like aerospace and manufacturing. This resilience to pressure ensures that systems operate more reliably, reducing the chances of system failure, which could have catastrophic implications.

Versatile Application Across Industries

Gasket sealants are not limited to one specific type of application; they are versatile tools appropriate for various industries including plumbing, automotive, and aerospace. Their adaptability allows them to seal irregular surfaces effectively. The ability to fill gaps and crevices makes these sealants indispensable for ensuring tight fittings in challenging applications.

Easy Application and Maintenance

One of the attractive aspects of using gasket sealants is the straightforward application process. Most sealants are designed for ease of use, requiring minimal tools and preparation. Properly applied, they offer a reliable seal that is both quick to install and easy to maintain. This simplicity can lead to efficiency gains during assembly and repairs.

Environmental Considerations

In today's ever-evolving market, there is an increasing need for sustainable practices, and gasket sealants that utilize eco-friendly materials are gaining traction. These modern sealants are designed to minimize Environmental Impact while still providing exceptional sealing performance. By choosing environmentally friendly options, companies can contribute to sustainability efforts while ensuring reliable leak prevention. Statistics show that eco-conscious industries see a significant increase in consumer trust and loyalty.