Corte a Plasma: Fabricação de Metais

Introduction to Plasma Cutting Technology

Understanding the Fundamentals

Plasma cutting is a thermal process that uses a high-velocity jet of ionized gas, known as plasma, to cut through various materials. This ionized gas, with its intense heat, melts and vaporizes the material at the cut's edge, creating a precise and clean separation. Understanding the principles behind plasma cutting is crucial for achieving optimal results and ensuring safety.

Plasma cutting technology has evolved significantly over the years, leading to advancements in precision and efficiency. The technology relies on generating a highly conductive arc that channels the plasma jet, allowing for controlled material removal and minimal heat-affected zones. This allows for greater control over the cutting process itself.

Types of Plasma Cutting Systems

Different plasma cutting systems cater to various applications and material thicknesses. There are several types of plasma cutting systems available, each with its own strengths and weaknesses. A key factor to consider is the type of nozzle and its compatibility with the specific material being cut.

Material Compatibility

Plasma cutting is suitable for a wide range of metallic materials, including steel, stainless steel, aluminum, and copper. The choice of plasma cutting system and its parameters, such as voltage, amperage, and gas type, can significantly impact the cutting quality and efficiency when working with different materials.

Safety Precautions

Plasma cutting involves high temperatures and pressures, requiring strict adherence to safety protocols. Always wear appropriate safety gear, including eye protection, hearing protection, and protective clothing, to mitigate potential risks. Ensuring the workspace is properly ventilated and clear of flammable materials is also critical to prevent accidents.

Proper maintenance and handling of the plasma cutting equipment are essential to avoid potential hazards and ensure the safety of both the equipment and the operator.

Cutting Parameters and Their Impact

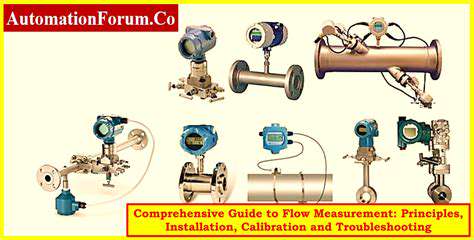

Various parameters influence the quality and efficiency of plasma cutting, such as voltage, amperage, gas type, and cutting speed. Adjusting these parameters allows for precise control over the cutting process, impacting the quality of the cut and the amount of heat-affected zone.

Applications and Industries

Plasma cutting finds extensive use across numerous industries, from automotive manufacturing to construction and metal fabrication. The ability to cut various metal types with high precision makes it a versatile tool for diverse applications.

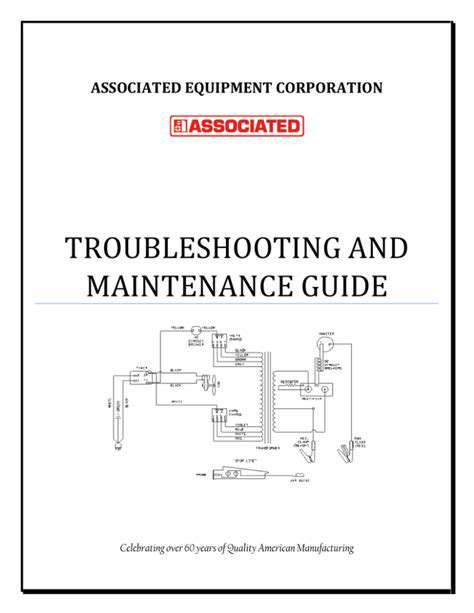

Maintenance and Troubleshooting

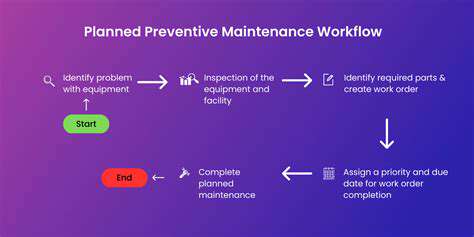

Regular maintenance is crucial to ensure the longevity and optimal performance of plasma cutting equipment. Troubleshooting any issues promptly can prevent further damage and downtime. Understanding the common causes of problems, such as arc instability or nozzle clogging, will help to maintain the system effectively.

Applications of Plasma Cutting in Modern Industries

Precision Cutting in Manufacturing

Plasma cutting is a highly precise method used extensively in various manufacturing processes. Its ability to cut through a wide range of materials with controlled kerf widths allows for intricate designs and complex shapes to be realized. This precision is crucial in industries such as aerospace, automotive, and construction where accurate part fabrication is essential. The consistency of the cut quality is a significant advantage, leading to higher yields and reduced waste. This precision also enables the creation of complex shapes that would be challenging or impossible to achieve with other cutting methods.

Furthermore, the ability to cut through thick materials with minimal distortion is a significant benefit in manufacturing. This characteristic is particularly valuable when working with heavy-gauge metals and alloys, enabling the creation of robust and durable components. Plasma cutting's consistent performance and precision are making it increasingly popular in automated manufacturing settings, enhancing efficiency and reducing production time.

Material Removal and Waste Reduction

Plasma cutting excels at efficiently removing material, minimizing waste and maximizing output. The controlled nature of the plasma arc ensures that only the necessary material is removed, drastically reducing scrap compared to other cutting methods. This efficiency translates directly to cost savings for manufacturers, especially in high-volume production environments. The targeted removal of material is a key factor in the overall cost-effectiveness of plasma cutting.

By precisely removing unwanted material, plasma cutting minimizes the amount of scrap generated during the manufacturing process. This reduction in waste has a significant environmental impact, contributing to a more sustainable approach to production. The controlled nature of plasma cutting allows for greater precision in material removal, leading to higher yields and less waste. This environmental benefit, combined with the economic advantage, makes plasma cutting an attractive choice for modern manufacturers.

Metal Fabrication and Repair

Plasma cutting plays a vital role in metal fabrication, enabling the creation of various metal components. From simple shapes to intricate designs, plasma cutting provides the precision and speed necessary for a wide range of applications. Its capability to cut through different metal thicknesses and alloys makes it a versatile tool in fabrication shops. The ability to cut through multiple materials with consistent results is a major advantage in the fabrication process.

Beyond fabrication, plasma cutting is also valuable in metal repair. Its ability to cut accurately through various materials allows for precise removal of damaged sections, enabling the repair and restoration of metal structures. This characteristic is particularly helpful in maintaining essential equipment and infrastructure. The precise cutting capabilities of plasma technology enable efficient and effective repairs, minimizing downtime and maximizing the lifespan of critical assets. This makes it a crucial tool for industrial maintenance and repair operations.

Applications in Diverse Industries

The versatility of plasma cutting extends beyond specific industries, finding applications in a wide range of sectors. Its use in the construction industry for cutting steel beams and other structural components is well-established. The precision and speed of plasma cutting make it an ideal choice for tasks requiring speed and accuracy. The ability to cut through different metals and thicknesses makes it a valuable tool in various industrial settings.

From the automotive and aerospace industries to fabrication shops and construction sites, plasma cutting is a powerful tool with diverse applications. Its precision and speed enable the creation of complex parts and structures, while its ability to minimize waste and maximize output contributes to cost savings and efficiency. Plasma cutting's versatility and efficiency are making it an indispensable tool in a wide array of industrial settings. It is a key component in modern manufacturing and maintenance operations.