Soldagem TIG: União Precisa de Metais

Understanding the TIG Welding Process

TIG welding, or tungsten inert gas welding, is a precision arc welding process that uses a non-consumable tungsten electrode to create an arc. This arc melts the base metal, allowing filler metal (if used) to be added and create a strong weld. The process is highly controllable, allowing for intricate welds and a high degree of precision. This control over the weld pool is key to achieving high-quality results. The shielding gas, usually argon, protects the weld pool from atmospheric contamination, improving the weld's quality and strength.

The process involves carefully manipulating the welding torch and controlling the amperage and voltage to achieve the desired weld characteristics. This skill-based approach requires considerable training and practice. Mastering TIG welding takes time and dedication but yields exceptional results.

Essential Equipment for TIG Welding

TIG welding requires a specific set of equipment, including a welding machine, a tungsten electrode, a welding torch, and a shielding gas supply. The welding machine provides the necessary electrical current to generate the arc. A variety of tungsten electrodes are available, each suited for different applications and materials. The welding torch is crucial for directing the arc and controlling the weld pool. A reliable supply of shielding gas is essential for maintaining a stable arc and preventing contamination.

Proper selection and maintenance of this equipment are vital for achieving quality welds.

Safety Precautions in TIG Welding

TIG welding involves working with high voltages and potential hazards. Safety precautions are paramount to prevent accidents. Wearing appropriate personal protective equipment (PPE) is crucial, including welding helmets with proper shade numbers, gloves, and protective clothing. Always follow safety guidelines and regulations for your specific environment. Understanding the potential risks of electrical shock, arc flash, and exposure to harmful fumes is essential for a safe welding environment.

Regular maintenance of your equipment and adherence to safety protocols are critical for a safe and productive work experience.

Understanding the Different Types of Tungsten Electrodes

Tungsten electrodes come in various types, each with specific characteristics. These characteristics influence the welding process and the final weld quality. Different electrode shapes, sizes, and coatings affect the arc stability, heat input, and overall performance. Selecting the correct electrode for the specific application is crucial for success.

Preparing the Workpiece for TIG Welding

Proper preparation of the workpiece is essential for a successful TIG weld. This includes cleaning the surface to remove any contaminants, such as rust, paint, or scale. Preparing the metal's surface also improves the weld's strength and integrity. Careful surface preparation is critical to the quality of the weld.

TIG Welding Techniques and Applications

Various techniques and applications are possible with TIG welding. Different techniques are employed for different materials and desired weld types. These techniques include root passes, hot passes, and various filler metal applications. TIG welding is highly versatile and can be used for a wide range of applications, from automotive repair to aerospace manufacturing and jewelry crafting. This process's adaptability to various projects is impressive.

Understanding these techniques and the specific requirements of each application will enable skilled welders to achieve optimal results.

The Fundamentals of TIG Welding: Key Components and Principles

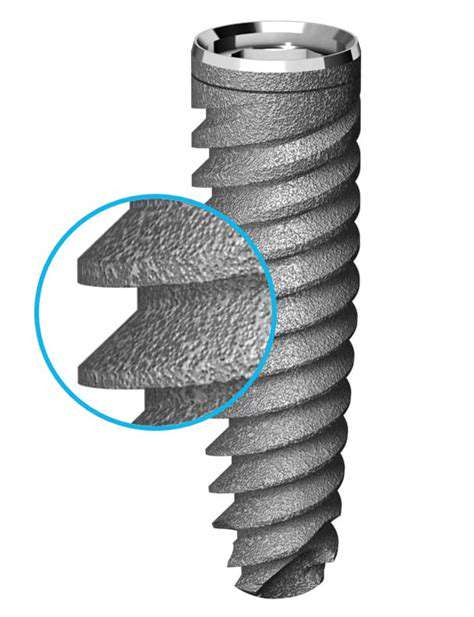

Understanding the Tungsten Electrode

The tungsten electrode, a critical component in TIG welding, is a non-consumable electrode made from tungsten. Its primary function is to create an arc between itself and the workpiece, initiating the welding process. Different grades of tungsten are available, each with varying characteristics suited to specific applications. Choosing the correct tungsten electrode type is crucial for achieving optimal weld quality and preventing issues like tungsten inclusions in the weld.

Tungsten electrodes come in various thicknesses and diameters, affecting the arc stability and heat input. Proper electrode selection is essential for consistent results. The electrode's purity also plays a significant role in arc stability and weld quality, influencing the amount of contamination in the weld pool.

The Role of the Shielding Gas

A shielding gas, usually argon or a mixture of argon and other gases, plays a vital role in protecting the weld pool from atmospheric contamination. This protective atmosphere prevents oxidation and other reactions that can compromise the weld's integrity and strength. The choice of shielding gas depends on the specific material being welded and the desired weld properties.

Precise gas flow control is essential for effective shielding. Insufficient gas flow can lead to porosity or other defects in the weld, while excessive gas flow can cause issues like excessive spatter. Understanding the relationship between gas flow rate and weld quality is paramount for achieving optimal results.

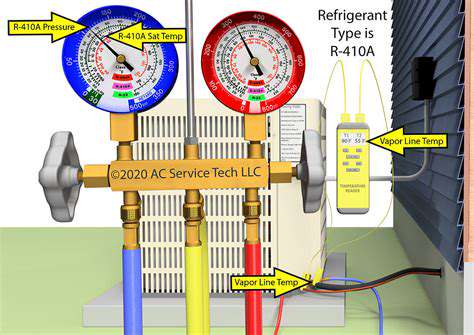

Analyzing the Welding Current

The welding current is a crucial parameter in TIG welding, directly influencing the arc's stability and the heat input to the workpiece. Proper current selection is vital for achieving a consistent and controlled weld pool. Too low a current can result in insufficient penetration, while too high a current can lead to excessive heat input, potential distortion, and overheating of the base metal.

Welding current settings are heavily influenced by the material thickness and type being welded. A deeper understanding of the material's properties and its response to different current levels is essential to achieve the desired weld characteristics.

Exploring the Contact Tip

The contact tip, often a copper or other conductive material, is the component that allows the electrical current to flow from the welding machine to the tungsten electrode. Its design and condition directly impact the arc's stability and the overall welding process. A damaged or improperly fitted contact tip can lead to inconsistent arc behavior, potentially resulting in poor weld quality.

The proper maintenance and selection of the contact tip is crucial for consistent performance in TIG welding. Regular cleaning and inspection of the contact tip can significantly improve the longevity and reliability of the welding process.

Understanding Arc Characteristics

The arc characteristics, including arc length, arc stability, and arc voltage, are critical factors in achieving a quality weld. An unstable arc can lead to defects in the weld, such as spatter or porosity. Maintaining a consistent and stable arc is a key aspect of TIG welding.

Factors influencing arc characteristics include the electrode type, gas flow, current settings, and even the ambient temperature. Understanding these influences is vital for troubleshooting and optimizing welding parameters for different materials and applications.

Navigating the Welding Techniques

Various TIG welding techniques exist, each suited to specific welding scenarios and workpiece requirements. Understanding these techniques allows for precise control over the weld bead shape, penetration, and overall weld quality. Different techniques emphasize various aspects of the welding process, tailoring the approach to diverse welding projects.

Techniques like weaving, or using different torch angles and feed rates, allow for the control of heat input and the creation of specific weld bead profiles. Mastering these techniques is essential for achieving high-quality welds.

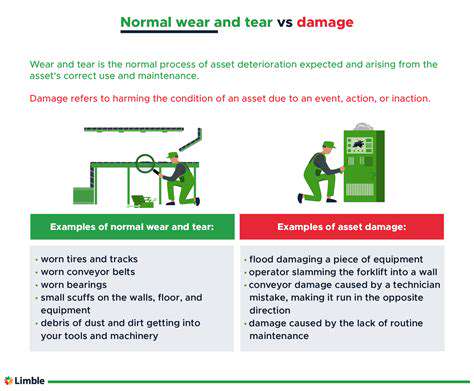

The Importance of Post-Welding Procedures

Post-welding procedures, including cleaning, inspection, and potential heat treatment, are just as important as the welding process itself. Proper cleaning of the weld area removes any contaminants that could compromise the weld's integrity. Inspection for defects like cracks or porosity is crucial to ensure the weld meets quality standards.

Heat treatment, when applicable, can further refine the weld's microstructure and improve its mechanical properties. Understanding and performing these post-weld steps is essential for achieving a robust and reliable final weld product.

Troubleshooting Common TIG Welding Issues and Improving Efficiency

Understanding TIG Welding Arc Issues

Troubleshooting TIG welding often involves identifying the source of arc instability. A weak arc can be caused by insufficient amperage or voltage settings, or by a poorly grounded work cable. This can also lead to inconsistent penetration and poor weld quality. A strong, erratic arc might indicate issues with the tungsten electrode, such as contamination or improper sharpening. Proper electrode preparation and consistent machine settings are crucial for a stable welding arc.

Inspecting the Tungsten Electrode

The tungsten electrode is the heart of the TIG welding process. A worn or contaminated electrode can significantly impact weld quality and cause erratic arc behavior. Regular inspection for nicks, chips, or excessive contamination is vital. Proper tungsten preparation, including cleaning and sharpening, is essential for consistent arc performance. Incorrect electrode size for the material being welded can also cause issues, resulting in inconsistent weld penetration and a poor welding experience.

Analyzing the Shielding Gas

A consistent supply of shielding gas is critical for protecting the weld pool from atmospheric contamination. Insufficient gas flow or improper gas type can lead to porosity, lack of fusion, and other weld defects. Gas leaks or improper gas nozzle placement can also disrupt the shielding gas envelope, leading to weld issues. Checking gas flow rate and ensuring proper nozzle placement are key troubleshooting steps for gas-related problems.

Evaluating the Workpiece and Clamps

The workpiece's condition plays a significant role in the welding process. Loose clamps or poor workpiece preparation can lead to inconsistent weld quality and arc instability. Rust, scale, or other contaminants on the workpiece surface can interfere with the welding process. Ensuring a clean and properly prepared workpiece surface, along with secure workpiece clamping, is essential to achieve a high-quality weld.

Checking the Welding Machine Settings

Incorrect welding machine settings can significantly impact the welding process. Adjusting the amperage and voltage settings to match the material thickness and desired penetration is crucial. Consistent machine settings are critical for a reliable welding process. Improper settings can lead to undercutting, excessive spatter, and poor weld quality. Proper understanding and adjustment of machine parameters are key to preventing welding problems.

Troubleshooting Electrode-Workpiece Contact

Maintaining consistent electrode-workpiece contact is vital for a stable arc and consistent weld quality. Improper contact can result in arc wandering, poor penetration, and spatter. Ensuring proper electrode angle and consistent contact pressure are crucial for a smooth welding process. Understanding and practicing the proper technique for electrode manipulation can dramatically reduce weld problems.

The Future of TIG Welding: Innovations and Advancements

Advanced TIG Welding Techniques

TIG welding, or tungsten inert gas welding, is a precision metal-joining process that is constantly evolving. New techniques are emerging, allowing for increased speed, accuracy, and control in various applications. These advancements leverage improved understanding of arc behavior and material interactions, leading to reduced weld spatter, improved weld penetration, and enhanced overall weld quality. The future of TIG welding is intrinsically linked to the development and implementation of more sophisticated techniques.

Innovations in robotic TIG welding are particularly noteworthy. Automated systems are becoming increasingly capable of performing complex and intricate welds with high repeatability, leading to significant improvements in production efficiency and consistency in high-volume manufacturing.

Improved Welding Equipment

The evolution of TIG welding equipment is a key driver of advancements in the field. Improved power sources, enhanced torch designs, and advanced gas delivery systems are enhancing the capabilities of TIG welding. These advancements not only improve the welding process itself but also offer increased operator comfort and safety, which contributes to a more efficient and productive work environment.

The development of more sophisticated control systems within welding equipment is leading to improved control over the welding parameters. This translates to greater precision and consistency in the weld quality, a key factor in demanding applications like aerospace and automotive industries.

Enhanced Materials and Alloys

The use of advanced materials and alloys in various industries is driving the need for more versatile and precise welding processes. TIG welding is adapting to these demands through the development of new welding techniques and processes that are capable of joining these specialized materials. Understanding the unique characteristics of these materials and their response to the welding process is crucial for achieving optimal weld quality and performance.

Advanced Inspection and Quality Control

Beyond the welding process itself, advancements in inspection and quality control play a vital role in ensuring the reliability and integrity of TIG welded components. Non-destructive testing (NDT) techniques, such as radiography and ultrasonic testing, are becoming increasingly sophisticated and integrated into the welding workflow. This ensures that welds meet stringent quality standards and eliminates potential defects early in the manufacturing process, preventing costly failures.

Automation and Robotics in TIG Welding

Automation is transforming the TIG welding landscape, allowing for higher production rates, enhanced precision, and reduced operator fatigue. Robotic TIG welding systems are becoming increasingly prevalent in various industries, including automotive manufacturing, aerospace, and shipbuilding. The integration of robotic systems into the welding process is not only about efficiency; it also allows for the execution of complex weld geometries and intricate patterns that would be difficult or impossible for human welders.

These advancements in robotic welding enhance consistency and reduce the margin for human error, leading to higher quality products and reduced manufacturing costs. Furthermore, robotic welding systems can operate in hazardous environments, further expanding the applications of this technology.

The Role of Digitalization in TIG Welding

Digitalization is revolutionizing the entire manufacturing process, and TIG welding is no exception. Digital tools and technologies are being employed to optimize welding parameters, monitor the welding process in real time, and collect detailed data for analysis and improvement. This data-driven approach to TIG welding allows for the identification of trends, the optimization of processes, and the identification of potential areas for improvement. These digital tools are also being used to improve the training and education of welders, leading to a more skilled and proficient workforce.

Sustainability and Environmental Considerations

The future of TIG welding also includes a growing focus on sustainability and environmental considerations. The development of more energy-efficient welding equipment, the use of cleaner welding gases, and the exploration of alternative energy sources are shaping the future of the process. Reduced energy consumption and the minimized environmental impact of welding operations are becoming increasingly important factors in the design and selection of welding technologies, reflecting a broader movement towards sustainable manufacturing practices.