CNC機床加工:精密零件生產

Turning

Turning is a fundamental CNC machining process that involves rotating a workpiece against a cutting tool. This process is highly versatile and capable of creating various shapes, including cylindrical surfaces, tapers, and grooves. The cutting tool, often a single-point tool, removes material from the workpiece in a controlled manner, enabling the production of precise and complex parts. Turning is frequently used for creating shafts, axles, and other components requiring rotational symmetry. The precision achievable in turning allows for high-quality parts, making it a crucial process in various industries, from automotive to aerospace.

Different turning operations cater to specific needs. For instance, facing operations are used to create flat surfaces on the ends of cylindrical parts, while knurling creates a textured surface for better grip. The choice of turning method depends on the desired part geometry and the material being processed. The controlled nature of the process, combined with the ability to quickly produce multiple parts with consistent tolerances, makes it an essential technique in modern manufacturing.

Milling

Milling is a CNC machining process that employs a rotary cutting tool to remove material from a workpiece. Unlike turning, which primarily creates cylindrical shapes, milling allows for the creation of a wider range of complex three-dimensional shapes. This versatility stems from the ability of the milling cutter to move in multiple directions, enabling the machining of surfaces with varying angles and profiles. Milling is extensively used to produce parts with intricate geometries, from the internal cavities of engine blocks to the intricate details of aerospace components.

Milling machines come in various types, each with its own capabilities. For example, vertical milling machines are excellent for machining surfaces perpendicular to the table, while horizontal milling machines are suited for machining flat or curved surfaces. The selection of the appropriate milling machine and cutting tool is crucial to achieving the desired outcome, ensuring that the part meets the specified tolerances and surface finish requirements.

Drilling and Boring

Drilling and boring are crucial CNC machining processes used to create holes of various sizes and depths in workpieces. Drilling typically involves creating a cylindrical hole, while boring is employed to enlarge or deepen an existing hole, or to create a more complex internal shape. These processes are fundamental in many manufacturing applications, from creating mounting holes to producing intricate internal passages. The accuracy and repeatability of CNC-controlled drilling and boring ensure that the holes meet precise specifications, which is vital in ensuring the functionality and performance of the finished product.

The precision of drilling and boring is directly related to the quality of the cutting tools and the stability of the machine. High-precision drills and boring tools, combined with rigid CNC machines, enable the creation of holes with extremely tight tolerances. These capabilities are essential in industries requiring extremely precise components, such as those in the medical and electronics industries.

Other CNC Machining Processes

Beyond turning, milling, drilling, and boring, a vast array of other CNC machining processes are available to manufacturers. These include, but are not limited to, broaching, gear cutting, and wire EDM (Electrical Discharge Machining). Each process is tailored to specific machining needs, offering unique advantages in terms of material removal, surface finish, and complexity of the parts produced. The choice of the appropriate process depends on the material, the desired geometry, and the required tolerances of the final part. Understanding the capabilities and limitations of each process is critical for optimal part design and production.

Selecting the right CNC machining process is crucial for achieving the best results. Careful consideration of factors such as material type, part geometry, required tolerances, and production volume is essential to make informed decisions and optimize the machining process. Manufacturers often utilize a combination of these processes to produce complex components that meet stringent quality standards.

Material Compatibility and Considerations

Material Compatibility Considerations for Long-Term Durability

Understanding material compatibility is crucial for ensuring the longevity and reliability of any engineered system. Different materials react differently to environmental factors like temperature, humidity, and exposure to chemicals. This reaction can lead to degradation, corrosion, or other detrimental effects, impacting the system's performance and lifespan. Proper material selection and consideration of long-term interactions are essential to avoid costly failures and maintenance.

Careful analysis of the interplay between different materials is key. For instance, certain metals may corrode in the presence of specific acids or bases, while polymers can degrade under UV radiation. Understanding these potential interactions upfront can prevent costly replacements and downtime later on.

Impact of Temperature Fluctuations on Material Performance

Extreme temperature fluctuations can significantly affect the performance of materials used in various applications. Changes in temperature can alter material properties like strength, stiffness, and elasticity, leading to potential structural issues. Understanding how materials respond to temperature changes is critical for predicting their behavior in different environments and ensuring system integrity.

For example, plastics can become brittle at low temperatures, while metals may lose their strength at high temperatures. Engineers must carefully consider the expected temperature range for the specific application and select materials that exhibit acceptable performance within those limits.

Corrosion Resistance and Protective Coatings

Corrosion resistance is a critical aspect of material compatibility, particularly in environments prone to chemical attack. Materials susceptible to corrosion require protective coatings or specialized treatments to extend their lifespan. Choosing the right protective coating can significantly improve the system's resistance to corrosion and prolong its service life.

Various types of protective coatings, such as galvanizing, painting, or plating, are available to enhance the corrosion resistance of different materials. The specific coating chosen will depend on factors like the aggressiveness of the environment and the desired level of protection.

Influence of Chemical Exposure on Material Degradation

Exposure to chemicals can significantly accelerate material degradation. Different chemicals interact with various materials in different ways, resulting in varying degrees of damage. Understanding the specific chemical environment and its potential impact on material performance is crucial for ensuring the long-term reliability of the system.

Mechanical Stress and Material Fatigue

Repeated mechanical stress can lead to material fatigue, which can result in cracks and failures over time. The design should account for expected mechanical loads, and materials should be selected based on their fatigue resistance. Understanding the material's stress-strain curve is essential for predicting its behavior under different loading conditions.

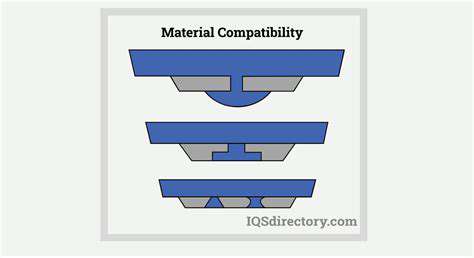

Material Compatibility in Multi-Component Systems

In complex systems composed of multiple materials, understanding the interactions between these materials is paramount. Compatibility issues between different components can lead to unforeseen degradation and failure. Thorough testing and analysis of the interactions between different materials in the system are necessary to ensure long-term performance.

Careful selection of materials and proper design considerations are critical to avoid incompatibility issues. This includes considering factors like chemical reactions, temperature fluctuations, and mechanical stresses to optimize system performance and longevity.

Environmental Factors and Material Performance

The environment plays a significant role in material compatibility. Factors like humidity, UV radiation, and presence of pollutants can affect material properties. Understanding the specific environmental conditions the system will be exposed to is essential for selecting suitable materials. This includes evaluating the long-term effects of these factors on the performance of the materials.

For example, materials exposed to high humidity levels may experience corrosion or swelling. Likewise, exposure to UV radiation can lead to degradation and embrittlement of certain polymers.