防鏽及除鏽:保護您的投資

Understanding the Rust Formation Process

Rust, the reddish-brown coating that forms on iron and steel, is a complex chemical process involving several stages. It begins with the oxidation of iron, a reaction between iron and oxygen in the presence of water. This initial stage creates iron oxide, a compound that further reacts with moisture and oxygen, leading to the formation of the familiar rust we see. Understanding the specific conditions that promote this reaction is crucial to preventing its formation and extending the lifespan of metal components.

The presence of electrolytes, such as salts or other minerals, accelerates the rusting process. These electrolytes increase the conductivity of the water, facilitating the flow of electrons and promoting the oxidation of iron. The environment plays a pivotal role as different conditions, such as high humidity or exposure to saltwater, provide ideal conditions for the chemical reactions involved in rust formation.

The Role of Water in Rust Development

Water is a critical component in the rusting process. It acts as a medium for the chemical reactions between iron and oxygen to occur. Even seemingly small amounts of moisture can be enough to initiate and accelerate rust formation. The presence of water, in its various forms, including atmospheric moisture and trapped water, is essential for the oxidation process to progress.

The type of water also influences the rate of rust formation. For example, saltwater, due to its high concentration of electrolytes, accelerates the rusting process significantly more than fresh water. This is why coastal regions often experience higher rates of corrosion compared to inland areas.

Identifying the Key Environmental Factors

Several environmental factors significantly contribute to the development of rust. These include variations in temperature, humidity levels, and the presence of corrosive substances in the air or water. High humidity levels increase the moisture content in the air, providing an ideal environment for rust formation.

Temperature fluctuations can also influence the rate of rusting, although the relationship is complex. While some temperature ranges can accelerate the process, others might slow it down. Extreme temperatures can also cause stress on metal structures, potentially leading to cracking and further corrosion.

The Impact of Corrosive Substances

The presence of corrosive substances, such as salts, acids, and certain chemicals, significantly accelerates the rusting process. These substances act as electrolytes, increasing the conductivity of moisture and enabling faster electron transfer, which ultimately leads to more rapid oxidation of the metal.

Exposure to industrial pollutants or chemicals, like acids, can create extremely corrosive environments, leading to rapid deterioration of metal surfaces. Understanding the specific types of corrosive substances present in a particular environment is crucial for implementing effective prevention strategies.

Common Rust Locations and Their Significance

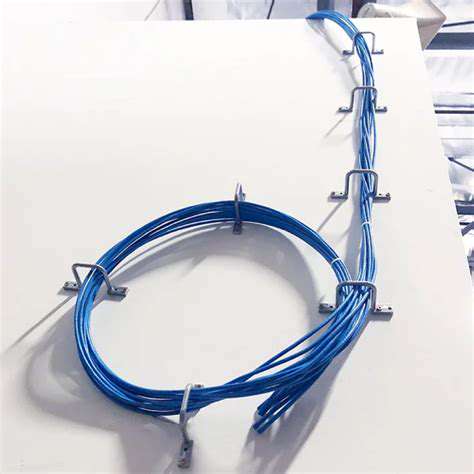

Rust often appears in areas exposed to the elements, such as rooftops, bridges, and pipelines. These locations experience greater exposure to moisture and other corrosive elements, making them more susceptible to rust formation. Identifying these vulnerable areas is essential for effective rust prevention and maintenance.

Preventive Measures and Their Effectiveness

Implementing preventive measures is crucial in mitigating the damage caused by rust. These measures include protective coatings, such as paints, and the use of corrosion-resistant materials. Regular inspection and maintenance of susceptible areas are also essential to detect and address potential problems early on.

Proper storage and handling of metal components, especially those exposed to moisture or chemicals, can significantly reduce the risk of rust formation. Understanding the specific conditions and factors contributing to rust in a given environment is key to developing an effective prevention strategy.

The Significance of Early Detection and Treatment

Early detection of rust is essential for preventing further damage to metal structures. Regular inspections of potential problem areas can help identify developing rust spots before they escalate into larger, more costly repairs. This proactive approach allows for timely intervention and prevents the spread of corrosion.

Prompt treatment of identified rust areas is crucial. Cleaning and treating the affected surfaces with appropriate rust inhibitors and protective coatings can prevent further deterioration and extend the lifespan of the metal. Ignoring early signs can lead to substantial structural damage and costly repairs.