Exhaust System

Vehicle Maintenance

System Analysis

Performance Evaluation

Acoustic Engineering

Mechanical Design

Resonator Selection

Engineering Design

HTML

Styling

消音器更換:精細調整排氣系統

逐步指南 (簡化版)

Read more about 消音器更換:精細調整排氣系統

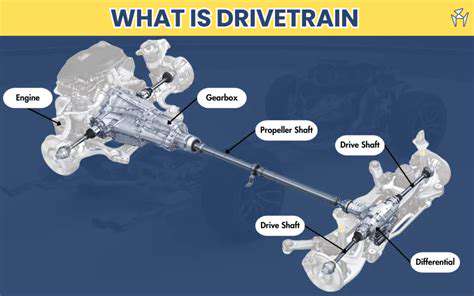

傳動系統零件及維護的綜合指南元描述:了解傳動系統零件的基本功能、常見問題及維護最佳實踐。透過我們的深入指南,學習如何延長您車輛傳動系統的壽命並確保最佳性能。內容描述:本指南提供傳動系統零件的全面概述,包括曲軸、凸輪軸、傳動軸及其在車輛運作中的關鍵功能。探討定期維護的重要性、過度磨損和過熱等常見問題,以及延長傳動系統壽命的實用技巧。了解高品質零件和適當潤滑實踐如何防止高昂的維修費用,提升車輛性能。了解傳動系統需要服務的跡象,確保安全可靠的駕駛體驗。

Jan 28, 2025