Convertible Top Repair: Keeping it Watertight

Addressing Fabric Tears and Punctures: Proactive Repair Strategies

Identifying the Source of the Tear

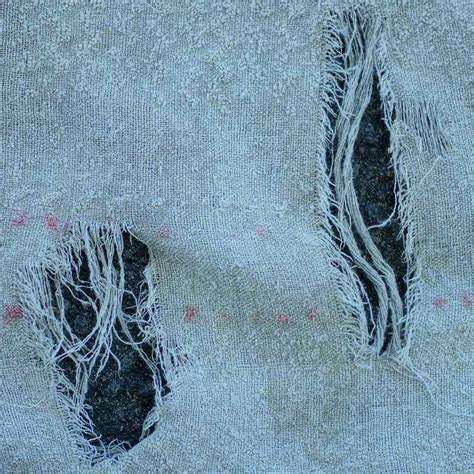

Determining the exact cause of a fabric tear is crucial for effective repair. Was it a sharp object? Perhaps a careless snag on something? Or was it a more gradual wear and tear issue? Understanding the origin of the damage will help you choose the best repair method and prevent future issues. Proper identification can save you time and money. Identifying the cause also helps in determining the best way to prevent future tears in the same area.

Sometimes, the tear might be a symptom of a larger problem, like a faulty seam or a weak point in the fabric's construction. If a tear occurs repeatedly in the same spot, it's definitely worth investigating the underlying cause to prevent further damage.

Assessing the Severity of the Tear

Once you've identified the source, it's important to carefully evaluate the extent of the tear. Is it a small, almost imperceptible nick, or a large gash that compromises the integrity of the fabric? The severity dictates the complexity and materials required for the repair. A small tear might require a simple stitch or a tiny patch, while a larger tear might necessitate a more substantial repair. A larger tear that extends through multiple layers requires a more involved method.

Choosing the Right Repair Method

A variety of repair methods exist, ranging from simple hand-sewing to more complex techniques involving patches and specialized tools. The best method depends on the size and location of the tear, as well as the type of fabric involved. Consider the specific requirements of the material when choosing a repair strategy. Careful selection of the repair method is paramount to achieving a lasting and aesthetically pleasing result.

Gathering Necessary Materials

Depending on the chosen repair method, you'll need specific materials. This might include sewing needles, thread that matches the fabric's color, fabric glue, a patch (if necessary), scissors, or a seam ripper. Carefully consider the needs of the repair technique you've selected and ensure you have all the necessary tools and supplies. A thorough inventory of materials will save you time and stress during the repair process.

Preparing the Fabric for Repair

Preparing the fabric for repair involves a few key steps. This might include trimming away any loose threads or frayed edges around the tear, ensuring a clean and stable base for the repair. Cleaning up the area of the tear is crucial for a professional-looking repair. Proper preparation is essential for a smooth and effective repair. It also minimizes the risk of further damage.

Executing the Repair

Following the chosen method, carefully execute the repair. This may involve precise stitching, careful application of glue, or the precise placement of a patch. Precise execution and attention to detail are critical to achieving a long-lasting and aesthetically pleasing repair. Accuracy in this step ensures the longevity of the repair. Thoroughness in executing the repair is key to a successful outcome.

Finishing Touches and Evaluation

Once the repair is complete, take the time to examine the area, ensuring that the repair is secure, smooth, and blends seamlessly with the surrounding fabric. A final inspection is crucial to confirm the integrity of the repair. Assessing the final result will help determine if the repair is satisfactory. A final check-up will give you confidence that the repair is strong and long-lasting. This helps prevent further issues.