Fuel Injector Cleaning: Optimizing Fuel Delivery

Clean fuel injection systems are crucial for modern engines, impacting everything from performance to emissions. These systems ensure precise fuel delivery, minimizing waste and maximizing efficiency. This meticulous control translates into improved fuel economy, reducing the environmental footprint of transportation, and contributing to a cleaner atmosphere. Incorporating advanced technologies into the design of these systems allows for tailored fuel mixtures, optimizing power output and responsiveness.

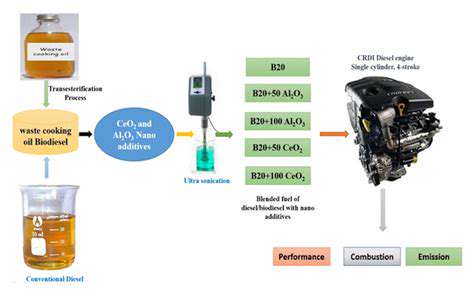

The introduction of cleaner fuel standards across the globe has further emphasized the importance of clean fuel injection. Engine manufacturers are constantly striving to meet these evolving regulations, resulting in innovative designs and methodologies to optimize fuel combustion. This commitment to cleaner technologies is essential for sustainable mobility and a healthier environment for future generations.

Optimizing Performance and Efficiency

Clean fuel injection systems play a pivotal role in optimizing engine performance. Precise fuel delivery allows for precise combustion, leading to greater power output and torque, particularly at lower engine speeds. This enhances the overall driving experience, allowing for smoother acceleration and better responsiveness. The improved fuel atomization in these systems ensures a complete combustion process, minimizing emissions and reducing harmful pollutants.

Furthermore, the intricate design of these systems contributes significantly to the efficiency of the engine. By minimizing fuel waste, these systems directly impact fuel economy, saving drivers money and reducing their environmental impact. This efficiency is crucial in today's world, where resource conservation and sustainability are paramount concerns.

Environmental Impact and Regulations

Clean fuel injection systems are critical in meeting increasingly stringent emission standards. These systems are designed to optimize combustion, reducing harmful pollutants like nitrogen oxides and particulate matter. This direct impact on air quality contributes significantly to a healthier environment, especially in urban areas where pollution levels are often high.

Governments worldwide are implementing stricter regulations to limit harmful emissions from vehicles. Clean fuel injection systems are a vital component in meeting these standards, helping to reduce the overall environmental impact of transportation. This commitment to cleaner technologies is essential for mitigating climate change and ensuring a sustainable future for all.

Technological Advancements and Future Trends

The field of clean fuel injection is constantly evolving, with new technologies continuously emerging to enhance performance and efficiency. Advanced materials and designs are being explored to further improve fuel atomization and combustion, leading to even greater reductions in emissions. These advancements promise to revolutionize the way we power our vehicles, offering a pathway towards cleaner and more sustainable transportation.

Future trends in clean fuel injection systems will likely focus on integrating advanced sensors, actuators, and control systems. This will enable even more precise fuel delivery, allowing for dynamic adjustments in response to varying driving conditions. This continuous innovation will further optimize fuel efficiency and reduce emissions, paving the way for a greener future. Furthermore, the integration of renewable energy sources will further necessitate the development of even more advanced and adaptable clean fuel injection systems.

Identifying Signs of Clogged Fuel Injectors

Understanding the Mechanics of Fuel Delivery

A clogged fuel system can stem from various issues, ranging from tiny particles obstructing the fuel lines to significant blockages within the fuel injectors. These blockages disrupt the proper flow of fuel to the engine, leading to a cascade of performance problems. Understanding the underlying mechanics of fuel delivery is crucial for diagnosing the root cause of the issue. A well-functioning fuel system ensures a consistent and reliable supply of fuel, allowing the engine to operate optimally.

Fuel filters are essential components in any vehicle's fuel system. They act as a barrier, preventing impurities and debris from entering the engine. Over time, these filters can become clogged with dirt, rust, and other contaminants. This accumulation can hinder the smooth flow of fuel, leading to reduced performance and potential engine damage. Regular maintenance, including fuel filter replacements, is vital for preserving the health and longevity of the vehicle's fuel system.

Symptoms of a Clogged Fuel System

One of the most noticeable signs of a clogged fuel system is a decline in engine performance. This can manifest as sputtering, hesitation, or difficulty accelerating. A sputtering engine is a strong indicator that the fuel is not reaching the cylinders consistently. This can result in a significant loss of power, making driving uncomfortable and potentially dangerous.

Another tell-tale sign is a rough idle. When the engine is idling, it should run smoothly and consistently. If it's sputtering or vibrating excessively, it could be an indication of a clogged fuel system. This erratic idling is often accompanied by a decrease in fuel economy.

Fuel Efficiency and Performance Issues

A clogged fuel system can significantly impact the fuel efficiency of your vehicle. When fuel delivery is compromised, the engine struggles to burn the fuel effectively, resulting in lower mileage and increased fuel consumption. This issue can lead to a noticeable increase in your fuel bills over time.

Decreased engine power is another common symptom. The engine may feel weaker and less responsive than usual. This is because the fuel isn't reaching the cylinders in the proper amount or at the correct time, impacting the power output. Reduced engine power can severely impact daily driving experiences.

Potential Causes of Fuel System Blockages

Several factors can contribute to fuel system blockages. Poor fuel quality, containing excessive contaminants, can quickly clog fuel filters and injectors. This highlights the importance of using high-quality fuel that meets the standards of your vehicle. Also, improper maintenance practices, such as infrequent fuel filter replacements, can lead to significant blockages over time.

Diagnostic Procedures and Solutions

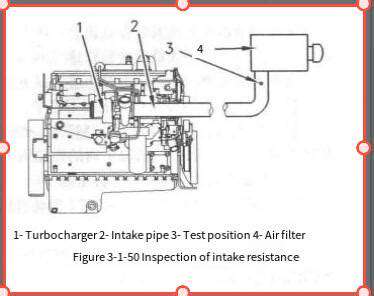

Diagnosing a clogged fuel system often involves a combination of visual inspections, performance tests, and potentially more advanced diagnostic tools. A mechanic will likely inspect the fuel filter, fuel injectors, and fuel lines for blockages. A thorough evaluation is essential to determine the extent of the clog and the appropriate repair strategy. Solutions range from simple fuel filter replacements to more complex cleaning and repair procedures, depending on the severity of the blockage.

Once the issue is identified, the appropriate repairs can be carried out. This may involve replacing fuel filters, cleaning fuel injectors, or addressing any other blockages in the fuel system. Properly addressing fuel system blockages is crucial for restoring optimal engine performance and preventing further complications.