Best practices for maintaining off road vehicles after intense use

Understanding the Foundation: Bearings and Shafts

Bearings are the unsung heroes of many mechanical systems, silently supporting and guiding rotating components. Proper lubrication, regular inspection for wear, and adherence to manufacturer specifications are crucial. Ignoring these aspects can lead to significant performance degradation, increased friction, and ultimately, premature failure. A thorough understanding of the specific bearing types used in your system, including their load capacities and operating temperatures, is paramount for effective maintenance.

Shafts, the axles and rods that transmit power, require similar attention. Visual inspection for cracks, corrosion, or excessive deflection is vital. Over time, shafts can experience stress-induced fatigue, leading to catastrophic failure. Implementing regular non-destructive testing, like ultrasonic analysis, helps identify potential issues before they escalate into costly repairs or downtime.

Gears and Gear Trains: Precision and Power

Gears are fundamental to transferring rotational motion and power in many mechanical systems. Maintaining proper lubrication, inspecting for wear and tear on teeth, and ensuring consistent alignment between gear sets are critical steps in preventing premature failure. Ignoring these aspects can result in noisy operation, reduced efficiency, and ultimately damaged gears. Understanding the specific gear ratios and load requirements of your gear train is essential for optimal performance.

Pulleys and Belts: Smooth Transitions

Maintaining the integrity of pulleys and belts is essential for smooth, continuous operation. Regular checks for wear and tear on the belt material, proper tensioning, and alignment of pulleys are paramount. A loose belt can lead to slippage, reduced efficiency, and potential damage to the driven components. Checking for signs of damage or fraying on the belt is crucial. Furthermore, ensuring proper lubrication of the pulleys can minimize friction and improve their longevity.

Couplings: Connecting and Isolating

Couplings are vital components for connecting rotating shafts while allowing for some degree of misalignment and absorbing vibrations. Regular inspections for wear, proper tightening, and adherence to manufacturer recommendations are essential for maintaining coupling integrity. Inspecting for signs of cracks, damage, or excessive play is important. Failure to address these issues can lead to premature failure, potentially causing damage to connected machinery and leading to costly repairs.

Springs: Controlled Force and Energy Storage

Springs, often overlooked, play a crucial role in many mechanical systems. Checking for signs of fatigue, corrosion, or deformation is necessary. Understanding the spring's operating conditions, including load capacity and temperature ranges, is crucial. Springs that are improperly maintained or under excessive stress can lose their elasticity and fail to provide the necessary force or energy storage. Regular inspection and proper maintenance are key to maintaining the integrity and performance of your spring systems.

Cleaning and Lubrication: Keeping Your Off-Roader Pristine

Cleaning Procedures

A crucial aspect of maintaining optimal equipment performance is a diligent cleaning schedule. Regular cleaning prevents the accumulation of contaminants, including dust, debris, and various other foreign particles, which can hinder the smooth operation of machinery and lead to premature wear and tear. This proactive approach not only extends the lifespan of the equipment but also significantly reduces the risk of costly breakdowns and downtime.

Different cleaning methods should be tailored to the specific equipment and materials involved. For instance, delicate components might necessitate specialized cleaning solutions and techniques to avoid damage. Thorough rinsing and drying are essential steps to remove any residual cleaning agents, ensuring that no traces remain to compromise the lubrication process or introduce corrosive agents into the machinery.

Lubrication Strategies

Proper lubrication is paramount to the longevity and efficiency of any mechanical system. Lubricants act as a protective barrier, reducing friction and wear between moving parts. This reduces the risk of overheating and seizing, ultimately extending the equipment's lifespan and preventing costly repairs.

Choosing the correct lubricant type is critical. Using an inappropriate lubricant can lead to premature wear, reduced performance, and increased maintenance costs. Understanding the specific operating conditions and material compatibility of the equipment is essential for selecting the appropriate lubricant viscosity and type.

Frequency and Timing of Cleaning and Lubrication

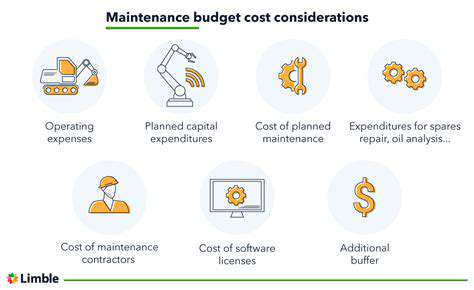

Establishing a consistent schedule for cleaning and lubrication is vital for preventive maintenance. Regular inspections and documented records are key components of any effective maintenance strategy. These records allow for tracking of maintenance activities, identifying patterns, and making informed decisions about future maintenance needs.

Factors such as operating conditions, environmental exposures, and the specific equipment design should all be considered when determining the optimal frequency of cleaning and lubrication procedures. A well-defined schedule reduces the likelihood of unexpected equipment failures and ensures consistent optimal performance.

Equipment-Specific Considerations

Different types of equipment require different approaches to cleaning and lubrication. For instance, high-speed machinery might necessitate more frequent lubrication to prevent overheating and maintain optimal performance. Consideration of the specific materials and environmental factors present in the work environment is crucial for selecting the right cleaning agents and lubricants.

Understanding the manufacturer's recommendations for each piece of equipment is essential. Following these guidelines ensures that the procedures are appropriate for the specific equipment and avoids potential damage or malfunctions. A proactive approach to understanding and adhering to manufacturer specifications is essential for maximizing the life cycle of each piece of equipment.

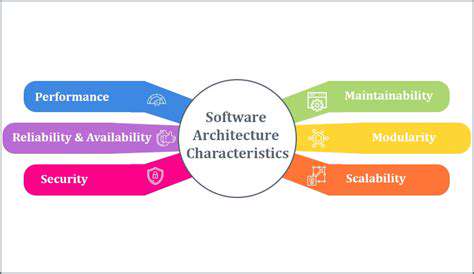

Addressing Electrical Issues and Electronics: Ensuring Smooth Operation

Identifying Potential Electrical Hazards

Electrical issues can range from minor inconveniences to serious safety hazards. Understanding the potential dangers is crucial for preventative measures. A faulty wire or overloaded circuit can lead to overheating and potentially cause a fire. Inspecting outlets, switches, and wiring for any signs of damage or wear is a vital first step in preventing electrical problems.

Improper grounding can also create significant risks. This can manifest in shocks or even more severe electrical malfunctions. Regular inspections by qualified professionals can help identify these issues early on, ensuring the safety of your home or business.

Troubleshooting Common Electrical Problems

Flickering lights, buzzing sounds, and tripped circuit breakers are common indicators of underlying electrical problems. These issues can often be resolved with simple troubleshooting steps, such as checking for loose connections or resetting tripped breakers.

However, some problems require specialized knowledge and tools. If you're unsure about the cause or severity of a problem, it's always best to seek professional help.

Understanding Circuit Overload

Electrical circuits are designed with a specific amperage capacity. Exceeding this limit can lead to overheating, potentially causing damage to the electrical system. Overloading a circuit frequently can damage wiring and lead to electrical fires. Recognizing the signs of overload is essential to prevent significant damage.

Importance of Regular Maintenance

Regular maintenance is crucial for maintaining the safety and efficiency of your electrical system. This involves checking for worn or damaged wires, ensuring proper grounding, and regularly inspecting outlets and switches. Proactive maintenance can significantly reduce the risk of electrical fires and costly repairs.

Routine checks, such as inspecting breaker boxes and looking for unusual smells, can help you identify potential problems before they escalate. This proactive approach can save you time, money, and potentially prevent serious safety risks.

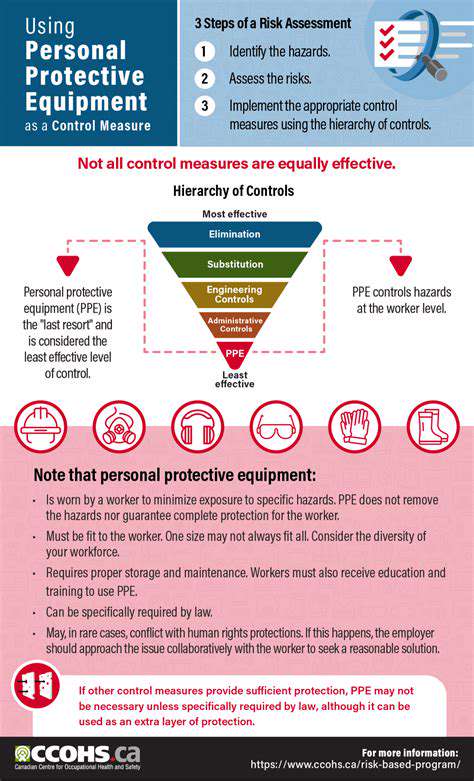

Safety Precautions When Working with Electricity

Working with electricity requires extreme caution. Always turn off the power supply before attempting any repairs or adjustments. Improper handling of electrical components can lead to serious injuries, including electric shock. Understanding basic electrical safety procedures is vital for anyone working with electrical systems.

Using appropriate tools and protective gear, such as insulated gloves and safety glasses, is essential. Never attempt repairs beyond your skill level; instead, consult a qualified electrician for complex issues.

Seeking Professional Electrical Services

For complex electrical issues or repairs beyond your expertise, seeking professional electrical services is highly recommended. Qualified electricians have the training, experience, and tools to diagnose and resolve electrical problems safely and efficiently. Hiring a professional ensures that the work is done correctly, preventing further damage and maintaining safety.

Identifying the need for professional help early on can save you from potential hazards and ensure a smooth resolution to any electrical problems. It's always best to err on the side of caution when dealing with electricity.

Choosing a Reputable Electrician

Selecting a reputable and licensed electrician is paramount for ensuring the quality and safety of electrical work. Look for certifications, licenses, and positive customer reviews to gauge the electrician's expertise and reliability. Choosing a trustworthy electrician safeguards your home or business from potential hazards and ensures the job is done correctly.

Thoroughly researching and interviewing potential electricians before hiring them is vital. This step will help you make an informed decision and guarantee a professional and safe electrical service.

Re-Assessing and Maintaining Your Tires: Crucial for Future Adventures

Tire Condition Assessment: A Proactive Approach

Regularly inspecting your tires is paramount to ensuring safe and enjoyable journeys. Look beyond the tread depth; examine the sidewalls for any bulges, cuts, or unusual wear patterns. Uneven wear can indicate alignment issues, while a significant amount of cracking or damage could compromise the tire's structural integrity, potentially leading to a blowout. Taking the time for this proactive check-up can save you from costly repairs or, more importantly, a dangerous situation on the road.

Visual inspection isn't enough. Feel the tread with your fingers. Are there any noticeable irregularities? A smooth or uneven surface could signal underlying problems. Check for embedded objects, such as nails or screws, which can cause punctures and compromise the tire's integrity. This proactive approach can prevent catastrophic failures, ensuring your safety and the longevity of your tires.

Understanding Tread Depth and Its Importance

Tread depth is a critical factor in tire performance. Proper tread depth provides crucial traction and grip, particularly in wet or slippery conditions. Adequate tread allows water to evacuate from beneath the tire, preventing hydroplaning. Reduced tread depth compromises grip, making it more difficult to control the vehicle, especially during emergency maneuvers. Regularly checking your tire tread depth is essential for safe driving and extending the lifespan of your tires.

Consult your vehicle's owner's manual for the recommended minimum tread depth. Using a tread depth gauge is a simple way to accurately measure the remaining tread. Maintaining sufficient tread depth is crucial for optimal traction and safety, especially during challenging driving conditions.

Rotating Tires for Balanced Wear

Rotating your tires is a vital part of maintaining even wear and extending their lifespan. Rotating tires involves strategically moving the tires from one position to another, ensuring that all four tires experience a similar amount of wear. This balanced wear pattern prevents premature deterioration and ensures consistent performance across all tires. Ignoring tire rotation can lead to uneven wear, affecting handling and potentially compromising safety.

Following the manufacturer's recommendations for tire rotation intervals is essential for optimal performance and safety. Consult your owner's manual for the specific guidelines. Consistency in tire rotation can significantly extend the life of your tires, reducing the cost of frequent replacements and promoting longevity of the tires.

Proper Inflation Pressure: A Crucial Element

Maintaining the correct tire inflation pressure is vital for several reasons. Incorrect pressure impacts fuel efficiency, handling, and the lifespan of the tires themselves. Under-inflated tires can lead to reduced fuel economy, increased risk of tire damage, and potential uneven wear. Over-inflated tires, on the other hand, can lead to reduced traction and increased risk of blowouts. Using a reliable tire pressure gauge to ensure the correct pressure is essential for optimal performance and safety. Checking tire pressure regularly is a simple but effective way to maintain your tires and your vehicle in optimal condition.

Maintaining Tire Pressure and Alignment

Proper tire pressure is critical for safe and efficient driving. Consistent monitoring and adjustment are essential for optimal performance and safety. Maintaining the correct tire pressure ensures that the tires are appropriately supporting the weight of the vehicle, which directly impacts handling and fuel efficiency. Regular checks, especially before long trips, are recommended to prevent unexpected issues on the road. Alignment issues can also contribute to uneven tire wear, so getting your alignment checked periodically is equally important. A professional alignment ensures the tires are properly positioned to maximize traction and minimize wear, contributing to overall vehicle safety and longevity.

Regular maintenance, including checking tire pressure and alignment, is vital for safe and efficient driving. Address any discrepancies promptly to avoid potentially hazardous situations and extend the life of your tires. This proactive approach to tire care can lead to significant cost savings and contribute to a safer driving experience.