Diagnosing and resolving fuel system vapor lock issues

Identifying Initial Symptoms

The diagnostic journey begins with carefully tracking your vehicle's performance quirks. Stay alert for any odd behaviors like hard starts, engine sputters, sluggish acceleration, or sudden power loss. Document when these issues surface - are they constant or only show up after long idles or heavy loads? Keeping detailed records of these warning signs is vital for accurate problem-solving.

Watch for fuel-related red flags too, like abnormal gas mileage, fuel leaks (you'll smell them or see wet spots underneath), or a fuel gauge that's gone haywire. Logging these observations with timestamps helps narrow down possible culprits and directs your next diagnostic moves.

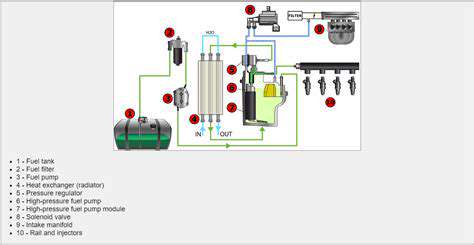

Checking Fuel Supply

Start your fuel system checkup by verifying the fuel delivery chain. Test the fuel pump's operation and confirm steady fuel movement from tank to engine. Examine the fuel pump relay and fuse first to eliminate electrical gremlins that might be choking fuel flow. Make sure fuel lines run clear without kinks, clogs, or leaks that could disrupt fuel's smooth journey.

Don't overlook the fuel filter - a dirty one can strangle fuel flow and cripple engine response. If you suspect blockage, swap it out and monitor performance changes. Also verify fuel pressure stays within factory specs since weak pressure often triggers misfires and other gremlins.

Inspecting the Fuel Injectors

Fuel injectors play the critical role of misting fuel for clean combustion. Give them a thorough once-over for any damage or malfunction clues. Search for clogs, leaks, or physical harm to the injector bodies. Spot anything suspicious? Break out a fuel injector tester to confirm proper spray patterns. A misbehaving injector can cause anything from rough idles to acceleration struggles.

Evaluating the Engine's Electrical System

Electrical faults can wreak havoc on fuel system operation. Check all wiring harnesses, sensors, and control modules tied to fuel delivery. Scan wires for damage like fraying or exposed metal. Verify critical sensors - MAF, fuel pressure, etc. - are functioning correctly. Faulty sensors can trick the ECM into making wrong fuel adjustments, sabotaging performance.

Don't forget the ignition system - confirm it's delivering strong, consistent sparks. A weak ignition system leads to incomplete burns that mimic fuel system issues.

Considering Fuel System Components

Expand your investigation to the fuel system's supporting cast. Examine injectors closely to confirm proper fuel atomization. Test the fuel pressure regulator's operation to ensure it maintains correct pressure - a bad regulator spells trouble. Scour fuel lines and hoses for leaks or obstructions that could disrupt steady fuel flow.

Finally, assess the fuel pump's vigor and the filter's condition. A tired pump might not sustain needed pressure, while a dirty filter strangles flow. These components often need professional attention when problems surface.

Repairing Fuel Vapor Lock Issues: Effective Solutions

Understanding Fuel Vapor Lock

Vapor lock happens when fuel turns to gas in the lines, choking off the engine's fuel supply. This typically occurs during heat waves or when the engine's pushed hard. Getting to the root causes is half the battle in solving vapor lock problems. The resulting stalling or hesitation isn't just annoying - it can be downright dangerous.

Several factors conspire to create this issue. Scorching weather hikes fuel's vapor pressure, making lock more likely. Fuel pump or delivery system troubles can also contribute to the problem.

Identifying Symptoms of Vapor Lock

Recognizing vapor lock's telltale signs allows for quicker fixes. Classic symptoms include engine hesitation, sputtering, or dying, especially when accelerating or working hard. These erratic behaviors often get misdiagnosed as other issues.

A noticeable power drop in hot weather is a dead giveaway. Pay close attention to how the engine responds when you step on the gas. If it balks or struggles to keep pace, vapor lock may be your culprit.

Inspecting the Fuel System

A meticulous fuel system inspection is your first line of defense against vapor lock. Check every inch of fuel lines and hoses for leaks, blockages, or damage. Confirm all connections are tight and lines aren't pinched or kinked.

Assessing the Fuel Pump

The fuel pump's health is critical for steady fuel delivery. A failing pump may not keep up pressure, especially when hot or stressed. A weak fuel pump ranks among vapor lock's prime suspects.

Testing fuel pressure provides valuable diagnostic clues. Low pressure often means insufficient fuel reaches the engine, setting the stage for vapor lock.

Examining the Fuel Tank and Lines

The fuel tank and its plumbing play vital roles in preventing vapor lock. Inspect the tank for rust or damage that could compromise fuel quality. Check lines for cracks or wear that might impede flow.

Considering the Engine's Temperature

Engine heat directly impacts fuel vaporization. Hot weather puts extra stress on the fuel system, raising vapor lock risks. High operating temperatures frequently trigger vapor lock episodes.

Taking steps to cool the fuel system can help prevent these frustrating incidents.

Implementing Solutions for Vapor Lock

Several fixes can combat vapor lock. Improving airflow around fuel lines and the tank helps lower fuel temperatures. Adding a quality fuel filter can enhance flow and reduce clog risks.

Fuel stabilizers extend fuel life and help prevent premature vaporization. Tackling root causes and taking preventive steps ensures smoother, more reliable driving.

Maintaining Your Vehicle's Fuel System: Preventive Measures

Regular Fuel Filter Changes

Swapping your fuel filter regularly keeps your fuel system clean and efficient. A clogged filter strangles fuel flow, hurting performance and potentially causing bigger issues later. Follow your manual's replacement schedule to guarantee clean fuel delivery, preventing clogs and maintaining peak operation. This simple step leads to smoother driving and extends your engine's lifespan.

The fuel filter acts as your engine's first defense, trapping harmful contaminants. Proper maintenance ensures your engine drinks only clean fuel, preventing expensive repairs down the road. It's an easy but impactful way to protect your vehicle's health.

Inspecting Fuel Lines and Connections

Regular fuel line checkups prevent leaks and ensure reliable fuel delivery. Look for cracks, corrosion, or loose fittings. Address any issues immediately to avoid dangerous leaks that could lead to expensive repairs or environmental harm. Small leaks often balloon into major problems affecting performance and safety.

A quick visual inspection can catch most fuel line issues early. This proactive approach saves money and keeps your fuel system running smoothly.

Monitoring Fuel Gauge Accuracy

A reliable fuel gauge prevents unexpected empty tanks. Malfunctioning gauges can strand you and lead to costly fixes. Regular accuracy checks against known fuel levels help spot problems early, ensuring you always know how much gas you've got.

Cleaning the Fuel Tank

Periodic fuel tank cleaning significantly impacts system longevity. Over time, gunk builds up, potentially harming fuel quality and engine performance. Cleaning removes these harmful deposits, preserving fuel quality and engine efficiency. It's an often-overlooked but critical maintenance task.

Using Premium Fuel (Where Appropriate)

Using your manufacturer's recommended fuel ensures peak performance and longevity. Premium fuel, when specified, boosts efficiency and prevents compatibility issues. This smart choice improves mileage, cuts emissions, and extends engine life. Always check your manual for the right fuel grade to maintain optimal system operation.

Addressing Fuel System Leaks Immediately

Quick leak repairs keep your vehicle safe and functional. Fuel leaks pose fire hazards and can damage components while harming the environment. Early detection and repair prevent these risks from escalating. Suspect a leak? Call a mechanic immediately.

Proper Storage Practices for Vehicles

Smart storage protects your fuel system during long downtimes. Letting a vehicle sit can degrade fuel and cause system issues. Store in dry, ventilated areas and use stabilizers to maintain fuel quality and prevent varnish buildup. These steps ensure your fuel system stays ready when you are.