Understanding the compatibility of biofuels with car engines

Engine Maintenance and Long-Term Considerations for Biofuel Use

Engine Modifications for Biofuel Compatibility

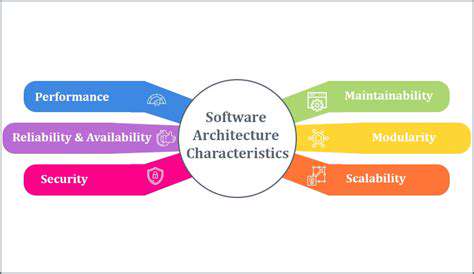

Implementing biofuel into existing engines often necessitates modifications to ensure smooth and efficient operation. Biofuels, particularly those derived from plant matter, can have differing properties compared to traditional petroleum-based fuels. This can lead to issues like increased corrosion, gum formation, and potential clogging of fuel lines and injectors. Careful consideration must be given to engine components like fuel injectors, pumps, and even the combustion chamber design to optimize biofuel compatibility. Engine Modifications might include upgrades to fuel delivery systems to accommodate higher viscosity or different chemical compositions in the biofuel, ensuring consistent fuel flow and atomization.

Furthermore, the use of biofuels might require alterations to the engine's cooling system. The different heat release characteristics and potential for higher temperatures during combustion with biofuels could necessitate adjustments to ensure proper cooling and prevent overheating issues. Careful consideration of these factors during the adaptation process is crucial to avoid costly and time-consuming repairs down the road. Engine modifications are often tailored to the specific type of biofuel being used, ensuring that the engine is adequately prepared to handle the unique characteristics of the chosen biofuel.

Long-Term Wear and Tear Impacts on Biofuel Engines

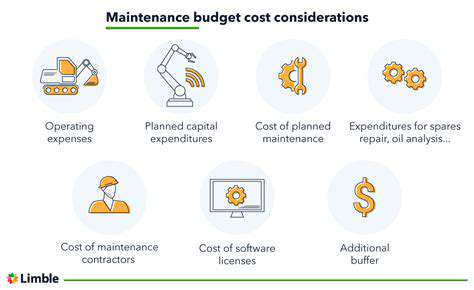

While biofuels offer a potential pathway towards a more sustainable energy future, understanding the long-term wear and tear they induce on engine components is essential. Biofuel use can result in accelerated wear on crucial engine parts like pistons, cylinder liners, and bearings, largely due to the varying properties of different biofuel blends. The presence of impurities or byproducts in certain biofuel types can contribute to increased friction and abrasion within the engine, leading to premature component degradation. Thorough maintenance schedules and component inspections become paramount to ensure the continued operational efficiency and longevity of engines incorporating biofuel.

Long-term considerations also encompass the potential for increased carbon deposits and varnish formation within the engine. Certain biofuels can promote the buildup of these materials, potentially impeding engine performance and increasing the risk of internal combustion problems. Regular cleaning and maintenance procedures, such as more frequent oil changes and filter replacements, are often necessary to mitigate the impact of these effects and sustain optimal engine performance over extended periods. Maintaining a consistent maintenance regime will help extend the life of biofuel-using engines and ensure their reliability.

Fuel Storage and Handling Considerations in Biofuel Systems

Proper fuel storage and handling practices are critical when utilizing biofuels. Biofuels, especially those with higher water content, can be susceptible to degradation and microbial growth if not stored and handled correctly. This can lead to issues like fuel gelling, clogging of fuel lines, and contamination, severely impacting engine performance. Implementing robust storage containers and tanks that can maintain optimal temperatures and humidity levels is essential. Careful control over these factors will significantly increase the longevity of biofuel stocks and minimize the risk of issues within the biofuel-fueled engine.

Implementing clear safety protocols is crucial to safeguard personnel and the environment when dealing with biofuels. The flammability and potential toxicity of certain biofuels demand adherence to strict handling procedures to prevent accidents. Thorough training for personnel responsible for handling and storing biofuels is paramount. Safeguards, like proper ventilation systems and fire suppression measures, need to be meticulously in place during both storage and handling. A commitment to safety throughout the biofuel handling process is essential for successful and sustainable biofuel utilization.