Fuel Injector Cleaning & Flow Testing

Understanding Injector Performance

Flow testing is a crucial diagnostic tool for evaluating the performance of injectors in various applications. It assesses the ability of the injector to deliver fuel at the desired rate and pressure, a critical component in ensuring optimal engine performance and efficiency. Proper flow testing procedures are essential for identifying potential issues early on, enabling preventative maintenance and avoiding costly repairs or replacements.

Understanding the principles behind injector flow is paramount to effective troubleshooting and maintenance. This includes understanding how different variables, such as pressure and temperature, affect the flow rate. A thorough understanding of these parameters allows for precise analysis and interpretation of test results.

Preparing for the Flow Test

Before commencing the flow test, meticulous preparation is essential. This involves ensuring the injector is properly prepared and that the necessary equipment, including specialized flow meters and pressure gauges, is calibrated and in proper working order. Incorrect calibration can lead to inaccurate results, hindering the diagnostic process.

Thorough cleaning of the injector is also vital. Contaminants, such as debris or fuel residue, can significantly impact flow characteristics. This meticulous preparation step guarantees reliable and accurate data collection.

Calibration and Validation

Accurate calibration of the flow test equipment is paramount for reliable results. Proper calibration ensures that the measured flow rates are precise and accurate, minimizing errors that could lead to misdiagnosis. Calibration procedures should adhere to stringent industry standards to guarantee the validity of test results.

Verification and validation of the test equipment are equally important steps. This involves checking the equipment against known standards and reference values to confirm its accuracy. This step is crucial to establishing confidence in the integrity of the flow test results.

Flow Rate Measurement and Analysis

Precise measurement of the fuel flow rate is a critical aspect of the flow test. Different methods, such as volumetric and gravimetric techniques, can be employed depending on the specific requirements and limitations of the test environment. Careful consideration of the measurement method is essential to ensure accuracy.

Pressure and Temperature Considerations

Injector performance is highly sensitive to pressure and temperature variations. These factors influence the fuel's viscosity and flow characteristics. Maintaining consistent pressure and temperature conditions during the test is crucial to obtaining accurate results. Variations in these parameters can lead to significant errors in the assessment of injector performance.

Careful monitoring and control of pressure and temperature throughout the test ensure that the results reflect the injector's performance under realistic operating conditions. This is essential for a comprehensive and accurate evaluation.

Reporting and Interpretation of Results

Detailed documentation of the test procedure, equipment calibration, and observed flow rates is essential for effective reporting and interpretation. This comprehensive record allows for a thorough analysis of the data and facilitates effective communication of findings. A clear and concise report, supported by accurate data, is crucial for informed decision-making regarding injector maintenance or replacement.

Interpreting the results requires a deep understanding of the expected flow rates for the specific injector type and application. Comparing the measured flow rates to these expected values reveals potential discrepancies and allows for a comprehensive assessment of the injector's performance.

Maintenance and Prevention Strategies

Cleaning Procedures

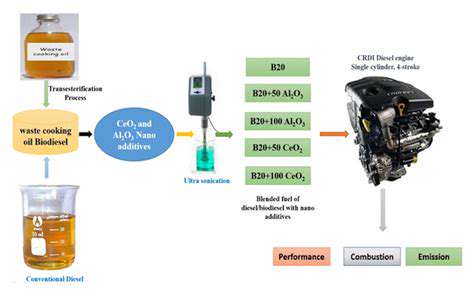

A crucial aspect of maintaining fuel injector performance is regular cleaning. This involves disassembling the injectors, carefully removing any accumulated deposits, and ensuring a thorough inspection for damage. Proper cleaning procedures are essential to restore optimal fuel flow and prevent future issues. Specialized cleaning solutions and ultrasonic baths can effectively remove carbon buildup and other contaminants, but always follow the manufacturer's recommendations for specific cleaning agents and procedures to avoid potential damage.

Before beginning the cleaning process, meticulously document the original condition of each injector. This detailed record-keeping will help track the effectiveness of the cleaning process and identify any recurring issues. Properly storing and handling the injectors throughout the cleaning procedure is vital to prevent scratches or damage, ensuring the injectors are ready for reassembly.

Flow Testing Methodology

Accurate flow testing is critical to evaluating the performance of each fuel injector. This process typically involves using specialized equipment to measure the precise amount of fuel delivered by the injector over a set period. The flow rate should be consistent across all injectors, and any significant variations can indicate potential issues that need further investigation.

Employing calibrated equipment and adhering to established testing protocols are paramount for obtaining reliable flow rate data. This data is essential for identifying injectors that are not delivering fuel at the required rate, which can lead to reduced engine performance or other operational problems.

Troubleshooting Fuel Delivery Issues

Fuel delivery issues can stem from various factors, including clogged injectors, low fuel pressure, or faulty components. A systematic troubleshooting approach is essential for identifying and addressing these issues effectively. Thorough inspection of the fuel system components, examining the fuel filter for blockages, and checking for leaks are crucial steps in the diagnostic process.

A critical aspect of troubleshooting is comparing the flow rate data from the testing process with the expected values. This comparison allows for the identification of any inconsistencies, enabling targeted interventions to resolve the fuel delivery problem. This process helps determine if the issue lies within the injectors themselves or in other parts of the fuel system.

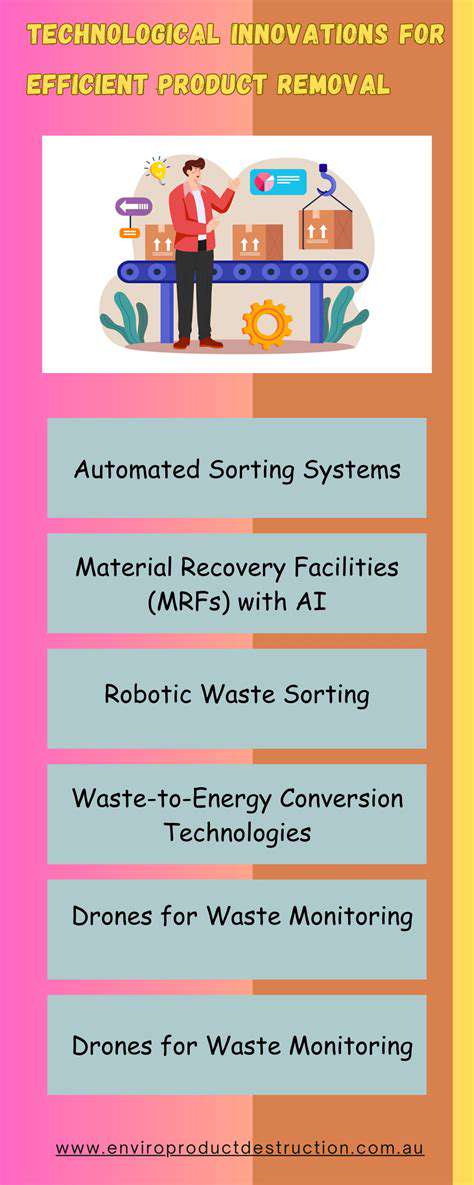

Preventive Maintenance Practices

Implementing preventive maintenance strategies is key to extending the lifespan of fuel injectors and minimizing the likelihood of issues. Regular checks for fuel pressure and fuel filter condition, as well as routine cleaning of the fuel injectors, are all integral aspects of a comprehensive preventive maintenance plan. These measures can significantly mitigate the risk of costly repairs and downtime.

Injector Component Inspection

A thorough visual inspection of each fuel injector component is essential to identify potential wear or damage. Inspecting the injector nozzles, the internal passages, and the seals for any signs of deterioration is vital to determining the overall health of the injector. Identifying these issues early can prevent more significant problems down the road.

Fuel System Considerations

Maintaining a clean and well-functioning fuel system is crucial for the overall performance and longevity of the fuel injectors. Regular checks on fuel filters, fuel pressure regulators, and fuel lines are vital to ensure consistent fuel flow and prevent the accumulation of contaminants that can clog the injectors. A clean fuel system is essential for optimal fuel injector performance.