Essential checks for maintaining robust car suspension systems

Initial Visual Assessment

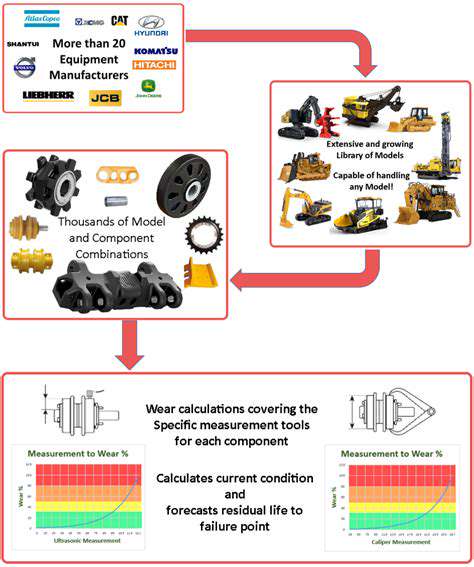

A quick visual inspection is the first line of defense in maintenance. This involves a thorough, yet rapid, assessment of the equipment's overall condition. Look for any obvious signs of damage, wear, or unusual operation. This initial scan can identify potential issues before they escalate into major problems, saving time and money in the long run. Pay close attention to areas prone to wear and tear and any components that appear loose or misaligned.

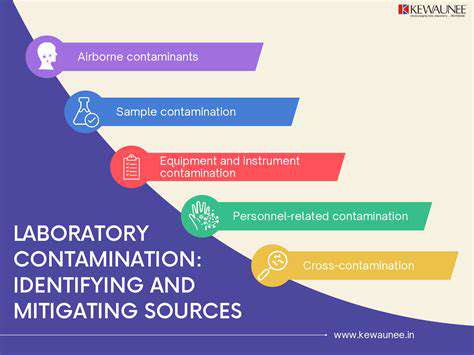

Checking for Leaks and Damage

A critical aspect of visual inspection is identifying leaks. Look for drips, spills, or any evidence of fluid or material escaping from the system. Pay attention to connections, seals, and gaskets for any signs of damage or deterioration. Leaks can indicate a problem with the integrity of the system and can lead to further damage and safety hazards if not addressed promptly. This includes inspecting for cracks, dents, or any signs of physical impact on the equipment.

Evaluating Component Functionality

Inspect each component for its proper function. Does it operate smoothly and without unusual noises or vibrations? Is it aligned correctly and securely attached to the system? This stage includes checking the functioning of any moving parts and ensuring they are operating at their expected speeds and without unusual sounds. Look for any signs of binding, jamming, or unusual movements, as these could indicate a serious mechanical problem.

Monitoring for Wear and Tear

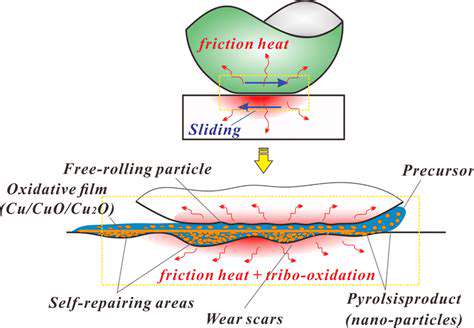

Visual inspection is crucial for detecting wear and tear. Look for signs of excessive friction, corrosion, or degradation in the materials. Pay attention to any component that shows signs of fatigue, pitting, or rust. Identifying wear and tear early can help prevent more serious failures and allow for timely maintenance actions. A careful visual examination can highlight areas of high wear, providing insight into potential stress points within the system.

Assessing Operational Efficiency

While visually inspecting, observe the overall operational efficiency of the system. Does it run at its expected speed and output? Are there any unusual noises or vibrations that might indicate a problem? Note any unusual behaviors or deviations from the expected operation. A careful and systematic check can uncover subtle signs of inefficiency, allowing for proactive measures to maintain optimal performance and prevent potential breakdowns. This is a crucial step in identifying potential operational bottlenecks.

Identifying Potential Safety Hazards

Safety should always be the top priority during any inspection. Look for any potential hazards, such as loose wires, exposed wiring, or damaged insulation. Ensure that safety guards are in place and functioning correctly. Are there any tripping hazards or areas where workers might be exposed to potential injury? Early identification of these hazards can prevent accidents and ensure a safe working environment. This critical aspect of visual inspection can significantly contribute to maintaining a safe workplace.

Checking Tire Pressure and Alignment: Crucial for Suspension Stability

Understanding Tire Pressure

Proper tire pressure is critical for maintaining a stable suspension system. Insufficient pressure leads to uneven tire wear, reduced fuel efficiency, and compromised handling. Over-inflation, while potentially offering a slightly firmer ride, can also cause discomfort and potentially affect the tire's ability to grip the road effectively, particularly on rough surfaces. Regular checks using a reliable pressure gauge are essential for ensuring your tires are properly inflated to the manufacturer's recommended pressure, which is typically found in your vehicle's owner's manual or on a sticker located inside the driver's side doorjamb.

Knowing the correct tire pressure for your vehicle's specific conditions is vital. Factors such as the weight of your vehicle, the type of driving you typically do, and the outside temperature all play a role. Adjustments might be needed in extreme weather conditions, and consulting a professional, if needed, can ensure you have the most accurate pressure readings for your situation.

Importance of Tire Alignment

Tire alignment, often overlooked, is just as crucial as tire pressure for suspension stability. Incorrect alignment can lead to premature tire wear, causing uneven tread patterns and a noticeable decrease in tire lifespan. This misalignment also affects your vehicle's handling characteristics, potentially making steering feel less responsive or causing the vehicle to pull to one side. Regular alignment checks, ideally performed by a professional mechanic, ensure your tires are properly aligned with the vehicle's suspension system, maximizing their contact with the road for optimal handling and safety.

Consequences of Neglecting Pressure and Alignment

Neglecting proper tire pressure and alignment can lead to a cascade of issues. From increased fuel consumption and reduced braking efficiency to increased risks of accidents due to poor handling, these neglects can translate to significant financial and safety concerns. Furthermore, these issues can strain other components of the suspension system, potentially leading to more expensive repairs in the long run. A proactive approach to maintaining proper tire pressure and alignment is a cost-effective way to ensure the longevity and safety of your vehicle.

Regular Maintenance for Optimal Performance

Regular maintenance checks, including tire pressure and alignment, are vital for the optimal performance and longevity of your vehicle's suspension. Regular checks and prompt repairs can prevent costly issues down the line. By making tire pressure and alignment checks part of your regular vehicle maintenance schedule, you can contribute significantly to the overall safety and performance of your vehicle. Investing in preventative maintenance is more cost-effective than addressing major problems later on.

Professional Expertise for Accurate Diagnosis

While you can check tire pressure yourself, professional expertise is essential for tire alignment. A trained mechanic has the specialized equipment and knowledge to accurately diagnose and correct alignment issues. Utilizing professional services ensures that the alignment is precisely adjusted, restoring optimal handling and preventing further damage. This professional approach is key to maintaining the precise balance and performance of your vehicle's suspension system.

Evaluating Shock Absorber Performance: Dampening the Ride's Impacts

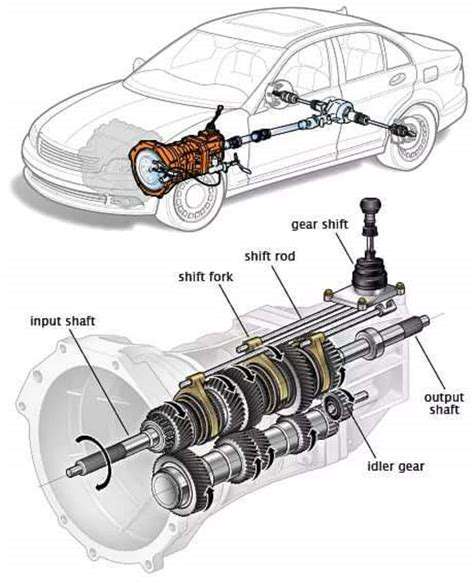

Understanding the Role of Shock Absorbers

Shock absorbers, often overlooked components of a vehicle's suspension system, play a crucial role in mitigating the impacts and vibrations that occur during driving. They are essentially hydraulic dampers that convert the kinetic energy of these impacts into heat, effectively smoothing out the ride and ensuring a more comfortable and controlled driving experience. Properly functioning shock absorbers maintain tire contact with the road surface, leading to improved handling, stability, and safety, especially during sudden maneuvers or traversing rough terrain. Understanding their functionality is key to appreciating their importance in overall vehicle performance.

Different types of shock absorbers are designed to accommodate various driving styles and vehicle types. From the classic gas-charged units to newer, high-performance models, the technology behind shock absorbers is constantly evolving. This evolution aims to provide optimized performance for everything from daily commutes to extreme off-road adventures. Understanding the specific characteristics of your vehicle's shock absorbers and their suitability for your driving needs can significantly enhance your overall driving experience.

Assessing Shock Absorber Performance Metrics

Evaluating shock absorber performance involves looking at several key metrics. One critical aspect is the rate at which they dampen oscillations. A well-performing shock absorber will quickly dissipate the energy from road imperfections, translating into a smooth and controlled ride. Measuring this damping rate is often done through specialized testing methods, which can help determine the effectiveness of a shock absorber in reducing vibrations and maintaining stability. This process helps to quantify the shock absorber's ability to transform impact energy into heat, which is crucial for optimal vehicle performance.

Another important metric is the shock absorber's ability to maintain consistent performance over time. Factors like material degradation, wear and tear, and environmental conditions can all influence a shock absorber's effectiveness. Regular inspection and maintenance are essential to ensure consistent performance and optimize the shock absorber's lifespan. A shock absorber's ability to handle varying loads and conditions is a crucial indicator of its reliability and suitability for a range of driving scenarios. This characteristic is often tested under controlled conditions to predict the shock absorber's performance over its intended lifespan.

Practical Methods for Determining Shock Absorber Condition

Beyond technical specifications, several practical methods can help assess the condition of your shock absorbers. Notice any noticeable bouncing or swaying when driving over bumps or uneven surfaces. This suggests that the shock absorbers may be losing their effectiveness in dampening the impacts. A noticeable difference in the ride quality compared to how it used to feel can also be a significant indicator of potential issues. This change in ride quality often signals the need for a thorough inspection of the shock absorber components and their overall condition.

Taking your vehicle for a test drive on different terrains can provide valuable insights into the shock absorber's performance. Noting how the vehicle handles corners, accelerates, and decelerates can provide more nuanced information. A significant difference in handling characteristics compared to previous experiences might indicate a need for replacement. Careful observation of the vehicle's response to different driving conditions, from smooth roads to rough terrain, can give you a better understanding of the shock absorber's effectiveness.

Furthermore, visually inspecting the shock absorbers for any signs of damage, such as leaks or visible wear, is important. Damaged shock absorbers may not be able to perform their intended function effectively. Checking for any unusual noises, such as squeaking or rattling sounds, is also crucial. These noises can indicate internal issues and potential problems with the shock absorber's components. Regular maintenance and inspection are essential for ensuring the longevity and optimal performance of your shock absorbers.

A well-designed invitation sets the tone for the entire event, acting as a crucial first impression. It's a sneak peek into the atmosphere you're hoping to create, and it's the first tangible piece of the event that your guests will physically hold and experience. Careful consideration of the design elements is paramount, as it conveys a sense of the event's style and importance. A simple yet elegant invitation can make a big difference in the overall experience, setting the stage for an unforgettable gathering.

Understanding the Role of Springs and Bushings: Maintaining Vehicle Stability

Spring Types and Applications

Springs, often overlooked, play a crucial role in a vast array of mechanical systems. They come in diverse forms, each tailored for specific applications. Understanding these different types is essential for selecting the appropriate spring for a given task. From simple helical springs used in door latches to complex leaf springs in vehicles, the variety is remarkable.

Different spring types, such as torsion springs, extension springs, and compression springs, exhibit unique characteristics in terms of their load-bearing capacity and deflection behavior. These variations are carefully engineered to meet specific demands, from absorbing shock to storing energy.

Material Selection for Springs

The choice of material for a spring is critical. Different materials possess varying strengths, elastic limits, and fatigue resistance. Selecting the right material ensures the spring can withstand the expected loads and stresses over its operational lifespan. This consideration is vital for ensuring the spring's longevity and reliability.

Factors such as tensile strength, yield strength, and modulus of elasticity are paramount in determining the optimal material for a specific spring application. Engineers carefully consider these properties to design springs that function reliably and safely.

Spring Design Considerations

Proper spring design is fundamental to performance and longevity. Factors like the spring's geometry, coil count, and wire diameter significantly impact its load-bearing capacity and deflection characteristics. Careful calculations and simulations are necessary to ensure the spring can handle the expected forces and avoid premature failure.

Spring Manufacturing Processes

Spring manufacturing involves precise techniques to achieve the desired form and characteristics. From wire drawing and forming to heat treatment and finishing, each step contributes to the spring's final performance. The precision of these manufacturing processes directly impacts the spring's functionality and reliability.

Spring Testing and Quality Control

Rigorous testing procedures are essential to ensure the quality and reliability of springs. Tests evaluate the spring's load capacity, deflection behavior, fatigue resistance, and overall performance under various conditions. These tests are vital in verifying that the spring meets the required specifications and safety standards.

Applications in Various Industries

Springs are ubiquitous, finding applications in diverse industries. From automotive engineering and aerospace to consumer electronics and medical devices, springs are integral components in a multitude of systems. Their ability to store and release energy makes them indispensable in many modern applications.

Their adaptability and efficiency make them essential to the smooth functioning of machinery and devices in virtually every industry. This adaptability is critical for maintaining a high level of functionality within various systems.

Impact on System Performance

Springs significantly impact the performance of entire systems. Their ability to absorb shocks, store energy, and provide controlled forces directly influences the system's overall functionality. Accurate spring selection and design are critical to achieving the desired system behavior. Understanding their role within the overall system is essential for optimization and efficiency.

The performance of a spring directly affects the performance of the entire system it is integrated into. Appropriate selection and design are critical for achieving desired outcomes.