MIG Welding: Versatile Metal Joining

Proper configuration is absolutely critical for achieving optimal results. Precise adjustment of wire feed rate, voltage levels, and current settings directly impacts weld quality. Additionally, correct gas flow rates and secure grounding connections are fundamental for both safety and performance. Comprehensive knowledge of the equipment and its proper arrangement forms the foundation for successful welding operations.

Types of MIG Welding Processes

The MIG welding family includes multiple specialized approaches, each designed for particular applications. These variations involve different electrode compositions, gas formulations, and technical methods. Selecting the appropriate wire type depends on the base metal and material thickness, while gas selection influences arc behavior and final weld properties. Recognizing these process variations enables welders to choose the most effective technique for their specific project requirements.

Safety Precautions in MIG Welding

Working with MIG welding equipment involves exposure to significant electrical hazards and other potential dangers. Implementing proper safety measures is non-negotiable to prevent workplace injuries. Essential protective gear includes certified welding helmets, flame-resistant clothing, heavy-duty gloves, and proper ventilation equipment. Maintaining an orderly work area and following established safety protocols significantly reduces risks during welding operations.

Understanding fire prevention strategies, electrical safety guidelines, and adequate ventilation requirements creates a safer working environment. Strict adherence to equipment manufacturer recommendations and local safety codes helps minimize potential hazards associated with MIG welding activities.

MIG Welding Applications

The versatility of MIG welding makes it invaluable across numerous industrial and personal projects. From large-scale construction projects and vehicle restoration to precision manufacturing and metal fabrication, this method provides reliable solutions for joining diverse metals. Its unique combination of speed and quality makes it equally effective for massive industrial operations and smaller, specialized tasks. Common applications include structural steel fabrication, automotive component repair, and various metalworking projects.

Troubleshooting MIG Welding Issues

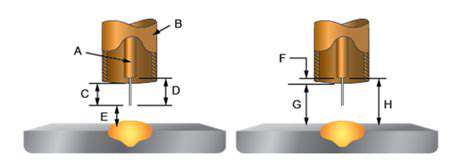

Welding defects can stem from multiple factors including improper machine settings, equipment problems, or operator mistakes. Addressing common problems like irregular bead formation, poor fusion, or insufficient penetration requires methodical analysis and adjustment. Recognizing the underlying causes of these issues facilitates efficient problem-solving and correction. Accurate identification of the problem source followed by appropriate corrective measures is essential for producing high-integrity welds.

Effective troubleshooting involves systematically evaluating power settings, wire feeding consistency, gas delivery, and electrical connections. Through careful examination of these elements, operators can pinpoint the root cause of welding defects and implement suitable solutions.

Feng Shui, the ancient Chinese art of spatial arrangement, emphasizes creating harmonious energy flow (Qi) within environments. This philosophy examines how natural elements - earth, water, wood, fire, and metal - interact within a space. By applying these principles, we can design areas that promote equilibrium, success, and wellness. This approach enhances a space's natural energy, creating a more positive and productive atmosphere for occupants.

Applications and Industries Utilizing MIG Welding

Automotive Manufacturing

MIG welding serves as a cornerstone technology in vehicle production, enabling precise joining of body panels, chassis components, and exhaust systems. The combination of consistent quality and high deposition rates makes it indispensable for meeting automotive manufacturers' rigorous production timelines and quality requirements. This process produces clean welds that often eliminate the need for additional finishing work, reducing overall manufacturing expenses.

From complete vehicle body assembly to intricate engine part fabrication, MIG welding proves essential. Its capability to join various steel grades, including the advanced high-strength steels prevalent in contemporary vehicles, guarantees the durability and safety of automotive structures.

Construction

The construction industry extensively employs MIG welding for numerous applications ranging from structural steel framing to concrete reinforcement bar connections. MIG welding's adaptability allows creation of robust joints in diverse metal profiles and gauges, making it fundamental for erecting bridges, high-rise buildings, and other major infrastructure projects. Its suitability for various welding positions and relative operational simplicity make it particularly valuable for field welding operations.

Shipbuilding

Marine construction depends heavily on MIG welding for assembling the myriad steel components comprising ship hulls, decks, and superstructures. The high-integrity welds produced ensure vessels can endure harsh ocean conditions. The capacity to weld substantial steel plate thicknesses combined with high deposition rates proves crucial for efficient construction of large marine craft.

MIG welding's precision and flexibility are vital for meeting the exacting specifications and safety requirements of shipbuilding. The ability to control weld bead characteristics and achieve quality results in all positions contributes significantly to successful marine construction projects.

Aerospace Industry

Aircraft manufacturing demands unparalleled precision in metal joining processes. MIG welding, capable of producing high-quality welds with minimal distortion, plays an important role in fabricating airframe components. Specialized filler materials and welding techniques ensure the structural reliability essential for flight safety and performance. The aerospace sector's rigorous quality assurance protocols favor welding methods like MIG that deliver predictable, verifiable results.

Pipe Fabrication

MIG welding serves as a preferred technique for pipe joining across multiple industries including utilities, petroleum, and chemical processing. Its ability to handle various pipe materials and diameters, combined with high deposition rates, makes it exceptionally productive for pipeline applications. The consistent weld quality achieved through MIG welding helps maintain pipeline integrity, preventing potentially catastrophic failures.

Metal Fabrication and Repair

In metalworking shops, MIG welding finds widespread use for creating custom components, repairing equipment, and fabricating structural elements. The combination of versatility, cost-effectiveness, and ease of operation makes it particularly attractive for fabrication and repair work. Its compatibility with different metals and material thicknesses supports applications ranging from minor repairs to major fabrication projects.