Advanced steps for ensuring consistent turbocharger operation

Addressing Potential Turbocharger Issues Through Preventative Maintenance

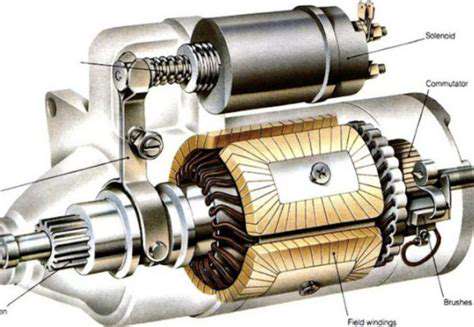

Understanding Turbocharger Function

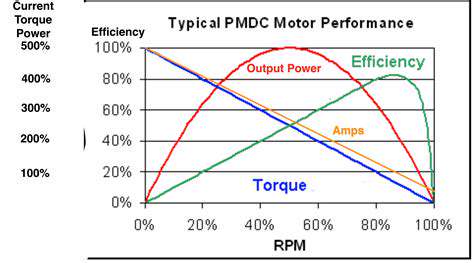

Turbochargers are crucial components in modern engines, significantly boosting power output. They operate by harnessing exhaust gases to spin a turbine, which then drives a compressor. This compressed air mixes with fuel for combustion, delivering increased horsepower and torque. Grasping this process is key to spotting potential issues early and taking preventative action.

Smooth operation depends on flawless interaction between the turbine and compressor. Any blockage or damage to these parts can trigger performance drops or even total failure. That's why knowing how a turbocharger works mechanically helps you stay ahead of problems before they escalate.

Monitoring Key Performance Indicators

Keeping tabs on key performance indicators (KPIs) is non-negotiable for catching turbocharger issues early. Boost pressure readings should always fall within the manufacturer's specified range—any deviation suggests internal wear or leaks that need attention.

Engine oil pressure matters just as much. Insufficient oil pressure causes overheating and damages turbocharger bearings, which are vital for smooth functioning. Always maintain proper oil levels and quality as outlined in your vehicle's manual.

Regular Oil Changes and Fluid Top-ups

Lubrication is the lifeblood of turbocharger longevity. Stick to the manufacturer's recommended oil change intervals to remove contaminants and keep critical components running smoothly. Skipping these changes accelerates wear, raising the risk of sudden failures.

Don't overlook other fluids either. Coolant and transmission fluid levels must be checked regularly to maintain optimal engine temperatures and overall system health—both indirectly supporting your turbocharger's durability.

Inspecting for Leaks and Damage

Make visual inspections around the turbocharger housing routine. Oil leaks, exhaust leaks, or visible damage demand immediate professional assessment. Catching leaks early prevents minor issues from snowballing into major repairs.

Cleaning and Maintaining Air Intake Systems

A clogged air intake strangles turbocharger efficiency. Dirt and debris restrict airflow, hampering performance. Clean the air filter and related parts frequently as part of your maintenance regimen.

Check air intake hoses for kinks or damage too. Even small obstructions here can undermine your turbocharger's output, so keep everything clear and intact.

Addressing Potential Exhaust System Issues

The exhaust system directly impacts turbocharger function. Blockages or restrictions here impair the turbine's spin, reducing boost pressure and risking damage. Regularly inspect exhaust components for leaks or obstructions.

Look for cracks or damage in exhaust pipes and manifolds during checks. Any red flags should prompt immediate professional attention to preserve your turbocharger's health and performance.

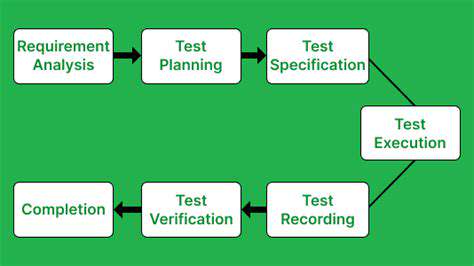

Advanced Techniques for Turbocharger Diagnostics and Troubleshooting

Understanding Advanced Diagnostic Tools

Basic gauges won't cut it for deep turbocharger diagnostics. Specialized tools measure exhaust gas temperatures, airflow rates, and compressor efficiency, painting a complete performance picture. Mastering these tools prevents misdiagnosis and ensures correct fixes.

High-end data acquisition systems capture real-time sensor data across operating conditions. Analyzing this information reveals subtle performance trends, helping engineers pinpoint issues that might otherwise go undetected.

Analyzing Sensor Data for Performance Indicators

Turbocharger health checks live and die by sensor data. Abnormal readings—like erratic boost pressure or spiking exhaust temperatures—signal problems ranging from turbine faults to actuator failures.

Trend analysis separates gradual wear from sudden failures. A steady boost pressure decline suggests component degradation, while wild swings may indicate sensor malfunctions or mechanical breakdowns.

Troubleshooting Common Turbocharger Issues

From power loss to total failure, turbo problems vary widely. Damaged vanes, worn bearings, and system leaks top the list. Effective troubleshooting requires methodical component checks and system evaluations.

Knowing how turbocharger parts interact helps isolate root causes. This knowledge ensures repairs target the actual problem rather than just symptoms.

Advanced Techniques for Component Inspection

Borescopes and ultrasonic testing reveal internal damage invisible to the naked eye. These methods catch micro-cracks and wear patterns before they trigger failures.

Implementing Predictive Maintenance Strategies

Predictive maintenance slashes downtime by anticipating failures. Monitoring KPIs and sensor data lets technicians intervene before minor issues become major repairs, maximizing uptime and efficiency.

Utilizing Computerized Diagnostics and Software

Modern diagnostic software crunches complex data sets, visualizing trends and flagging anomalies. These tools accelerate accurate diagnoses, getting systems back online faster with targeted solutions.