Signs of alternator failure and how it impacts electrical systems

Contents

- Dim headlights may indicate circuit problems caused by generator failure

- The dashboard battery warning light is an early alert of generator issues

- Unusual noises from the engine compartment often indicate wear on generator mechanical components

- Abnormal operation of onboard electronics reflects deterioration of the power supply system

- Repeated battery drain reveals a lack of the generator's charging function

- Speedometer readings fluctuating unveil hidden risks of unstable voltage

- Difficulty starting the engine points to precursors of power system failure

- Regular maintenance can effectively prevent generator-related faults

- Ignoring generator problems will lead to a chain of repair expenses

- Professional diagnostics are a necessary step to confirm the status of the generator

Timely detection of signs can prevent significant losses and ensure driving safety

Common Signs of Generator Failure

Abnormal Lighting and Circuit Issues

When the generator struggles to produce sufficient power, especially when idling, the first signs are often dim or flickering headlights. This phenomenon affects not only headlights but also dashboard backlighting and ambient interior lighting, with many drivers mistakenly believing it's due to aging light bulbs, delaying necessary repairs.

Slow operation of power windows and sudden black screens on central control displays are direct manifestations of insufficient power supply. These seemingly unrelated minor issues are actually reminders that the heart of the vehicle's electrical circuit may be failing. It is recommended to conduct a professional inspection upon noticing the first abnormal signal instead of waiting for multiple systems to fail simultaneously.

Illuminated Battery Warning Light

When the warning icon resembling a battery lights up, it actually indicates an abnormal charging function of the generator. This alert mechanism monitors circuit voltage, triggering when the system detects that the battery is discharging continuously rather than charging. According to statistics from the Motor Vehicle Electronics Association, vehicles sent for repair within 48 hours of the warning light turning on have an average reduction of 65% in repair costs.

Identifying Noises from the Engine Compartment

The sharp grinding sound of a slipping belt or the metallic grinding noise of damaged bearings often appear before dashboard warnings. Last week, a vehicle owner described the sound as if a cricket were holding a concert under the hood; upon inspection, it was discovered that the generator bearings were severely oil-deprived. These sounds vary in pitch with engine speed, serving as important indicators of mechanical failure.

Abnormal Operation of Onboard Electronics

Intermittent shutdown of the air conditioning compressor and frequent restarts of the navigation system expose instability in the power supply system. One Tesla owner experienced a sudden blackout of the central control display while driving on the highway, later confirmed to be caused by voltage fluctuations from the generator. These smart devices are particularly sensitive to voltage anomalies, serving as a barometer for the generator's status.

Short Battery Life Phenomenon

A new battery draining within half a year? This may not be a battery quality issue. The author has encountered extreme cases: one vehicle owner replaced seven batteries in three years, only to find that a malfunctioning generator regulator was causing overcharging. Measurements with a multimeter revealed a charging voltage as high as 16.8V, far exceeding the standard value.

Abnormal Speedometer Readings

Modern vehicles’ electronic speedometers are particularly sensitive to voltage fluctuations. Some owners have reported that while waiting at a red light, the needle inexplicably fluctuates by 5-10 km/h. This situation is often accompanied by confusion within the vehicle’s computer, and in severe cases, can even affect the operation logic of the ABS anti-lock braking system.

Signs of a Failing Starting System

When the starter motor makes a clicking sound but fails to ignite, it indicates that the battery is not receiving sufficient charge. A roadside assistance company's data shows that during emergency calls between 3-5 AM, 27% of cases were ultimately diagnosed as generator failure. This often occurs after prolonged use of onboard electrical devices, such as forgetting to turn off headlights while listening to music, leading to system failure.

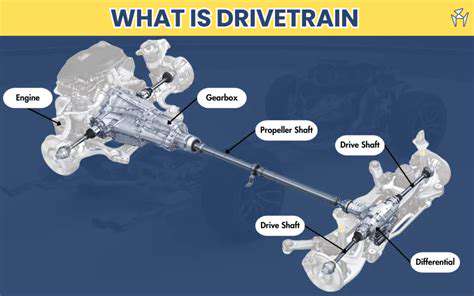

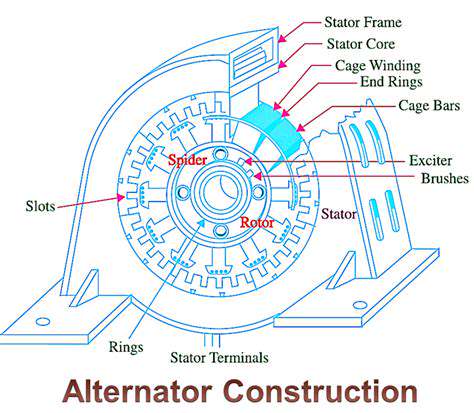

The Core Role of the Generator in the Power Supply System

The Mystery of Energy Conversion

This metal component with a diameter of about 20 centimeters can rotate up to 6000 times per minute. Through the principle of electromagnetic induction, it converts 30% of the crankshaft's mechanical energy into 50-120 amperes of direct current. Interestingly, the generator actually outputs three-phase alternating current, which is then converted into direct current required by the equipment through a rectifier bridge.

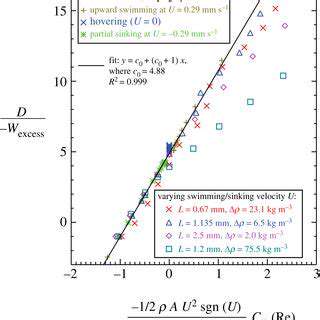

Three Stages of Fault Development

- Early: Voltage fluctuations of ±0.5V, sporadic electrical anomalies

- Middle: Output voltage drops below 13V, battery begins to drain

- Late: Complete cessation of power generation, vehicle can fail at any time

A repair shop once recorded that when the carbon brushes of a generator wore down to 2mm (the standard length is 10mm), the output voltage began to show a sawtooth pattern. This gradual process usually lasts 3-6 months, giving the owner sufficient warning time.

The Chain Reaction of Power Supply Failure

Overlooked Hidden Risks

In addition to the common difficulty in starting, generator failure can also lead to:

- Fuel injection system miscalculations, fuel consumption soaring by 15-20%

- Power interruption to the airbag control module

- Error messages from the transmission ECU causing shifting impacts

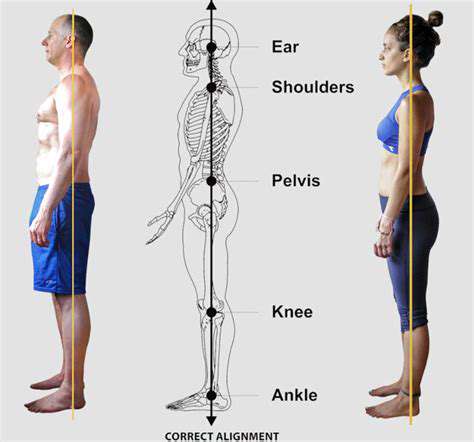

Simulation tests by an automotive safety laboratory show that when system voltage drops to 11V, the reaction time of electronic power steering extends by 0.3 seconds, which could have fatal consequences during emergency evasions.

Cost Assessment of Repair Delays

Economic and Safety Accounts

Taking a common mid-range sedan as an example, repair costs increase geometrically over time:

| Failure Stage | Repair Items | Cost Range |

|---|---|---|

| Early | Carbon brush/regulator replacement | ¥300-500 |

| Middle | Complete overhaul of generator | ¥800-1500 |

| Late | Replacement of generator + battery + wiring inspection | ¥2500-4000 |

Moreover, claims data from an insurance company indicates: in traffic accidents caused by power supply failure, 62% of vehicle owners had previously ignored early warning signals.

The Golden Rule of Maintenance

Check belt tension every 20,000 kilometers, measure carbon brush length every 50,000 kilometers; these simple preventive measures can extend the generator's lifespan by 3-5 years. Remember: checking the generator's sealing before the rainy season can effectively prevent water erosion and short circuits.