The importance of thorough inspections for rental fleet vehicles

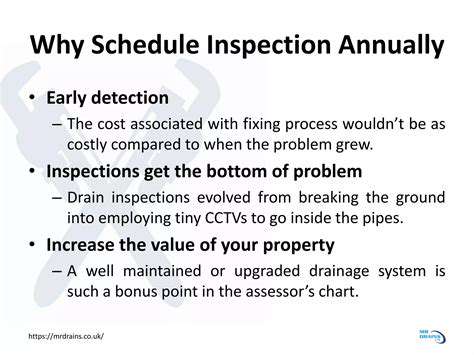

The financial wisdom of early intervention can't be overstated. Replacing a failing component before total failure occurs proves far more economical than emergency repairs. This reliability directly translates to customer trust - a priceless commodity in the rental industry. Detailed inspection logs create a valuable historical record, informing smart decisions about repairs, replacements, and future capital investments.

Protecting Your Business and Minimizing Liability

Beyond financial benefits, comprehensive inspections serve as legal armor for your business. Meticulously documented checks provide irrefutable evidence of due diligence should accidents occur. This paper trail can mean the difference between a minor incident and a devastating lawsuit, shielding your operation from potentially crippling legal consequences.

Safety hazards don't announce themselves - they're uncovered through vigilant inspections. Addressing these risks proactively creates safer environments for both employees and customers. This commitment to safety isn't just good ethics; it's smart business. A robust inspection protocol does more than maintain equipment - it safeguards your reputation, prevents costly legal entanglements, and ensures long-term operational stability.

The operational benefits extend beyond risk mitigation. Organized inspection records streamline maintenance scheduling and workflow efficiency. When teams embrace this proactive culture, they build a fleet management system that runs like well-oiled machinery. Ultimately, this systematic approach to inspections becomes your silent salesperson, attracting customers through demonstrated reliability and safety standards.

Identifying and Addressing Issues Early

Understanding the Importance of Proactive Inspection

Proactive inspections function like routine health check-ups for equipment. Catching problems in their infancy prevents expensive repairs, operational disruptions, and potential disasters. This forward-thinking strategy delivers long-term savings while eliminating the risks associated with sudden equipment failures. Regular, thorough examinations reveal early signs of wear, enabling timely and cost-effective solutions.

Recognizing the Signs of Deterioration

Effective inspections demand Sherlock-level attention to detail. Trained inspectors spot telltale signs - hairline fractures in materials, subtle corrosion patterns, or abnormal equipment vibrations. These minor symptoms often foreshadow major problems. Material-specific knowledge transforms inspectors into diagnostic experts, capable of interpreting each component's unique warning signs.

Implementing a Regular Inspection Schedule

Consistency separates effective maintenance from reactive repairs. A tailored inspection calendar, accounting for usage intensity and environmental factors, ensures comprehensive coverage. This disciplined approach catches issues during manageable stages, preventing them from escalating into budget-draining emergencies.

Utilizing Advanced Inspection Technologies

Modern diagnostic tools act as technological x-ray vision. Thermal imaging uncovers hidden heat patterns, while ultrasonic devices detect subsurface flaws invisible to naked eyes. These innovations transform inspections from superficial checks to deep diagnostic procedures, generating actionable data that informs smarter maintenance strategies.

Documenting Findings and Implementing Corrective Actions

Thorough documentation creates an equipment health journal. Photographic evidence, precise measurements, and detailed descriptions form a historical record that tracks asset condition evolution. Prompt action on identified issues separates effective operations from negligent ones, ensuring systems maintain peak performance and safety standards.

Training and Expertise for Effective Inspections

Skilled inspectors are the frontline defense against equipment failure. Continuous education keeps teams updated on emerging technologies and evolving best practices. A multidisciplinary inspection team provides comprehensive coverage, combining diverse perspectives to catch all potential failure points before they materialize.

Protecting Your Investment and Maintaining Safety Standards

Understanding the Importance of Thoroughness

Meticulous attention to detail forms the foundation of asset protection and safety compliance. This proactive mindset transforms maintenance from cost center to value preserver, preventing expensive mistakes while building operational resilience. Comprehensive understanding of systems and potential failure points leads to sustainable solutions that safeguard investments.

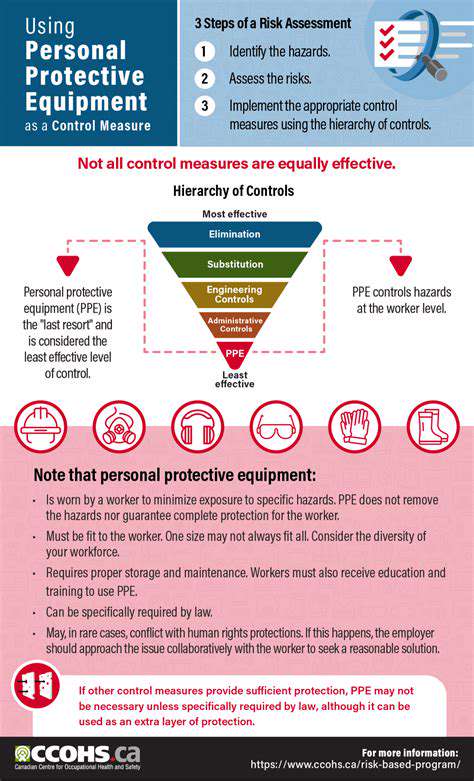

Planning for Potential Risks

Effective risk management begins with anticipating challenges before they emerge. A systematic approach to risk assessment evaluates both probability and potential impact. This forward-thinking strategy positions businesses to respond rather than react, minimizing operational disruptions while protecting both assets and personnel.

Implementing Safety Protocols

Safety systems only prove effective when understood and consistently applied. Regular protocol reviews adapt procedures to changing conditions and emerging threats. This living approach to safety evolves with the operation, ensuring continuous protection rather than static compliance.

Quality Control Measures

Rigorous quality standards act as a filtration system for operations. Integrated throughout all processes, these measures exceed basic requirements to deliver exceptional results. This commitment to excellence prevents defects before they occur, protecting both investment value and user safety.

Regular Maintenance and Inspections

Preventative care represents the most economical maintenance strategy. Structured inspection schedules combine routine checks with comprehensive evaluations. This layered approach catches issues at optimal intervention points, maximizing equipment lifespan while minimizing repair costs.

Employee Training and Awareness

Knowledgeable teams form the human firewall against safety breaches. Comprehensive training transforms employees from passive workers to active safety participants. This cultural shift embeds safety consciousness into daily operations, creating organic protection beyond procedural requirements.

Continuous Improvement and Adaptation

Static safety standards inevitably decay into obsolescence. Regular evaluation of procedures and technologies ensures ongoing relevance. This adaptive mindset future-proofs operations, maintaining protection as conditions and technologies evolve.

TV wall design enhances the aesthetic and functionality of living spaces

Ensuring Customer Satisfaction and Building Trust

Understanding Customer Needs

True customer understanding requires moving beyond demographics to grasp underlying motivations. This depth of insight transforms transactions into relationships, creating offerings that genuinely resonate. Systematic feedback analysis reveals improvement opportunities and innovation pathways.

Providing Excellent Customer Service

Exceptional service anticipates needs before they're expressed. Multiple support channels with rapid response times demonstrate commitment. Empathetic issue resolution often converts frustrations into loyalty, turning service moments into relationship builders.

Building Trust and Loyalty

Trust accumulates through consistent positive experiences. Transparency in operations and reliable performance establish credibility. Satisfied customers become voluntary ambassadors, their authentic endorsements more valuable than any advertising.

Implementing Feedback Mechanisms

Customer insights represent the compass for business improvement. Accessible feedback channels demonstrate receptiveness to input. Acting on suggestions proves commitment to customer-centric evolution, fostering collaborative relationships.

Maintaining Transparency and Communication

Open communication establishes psychological safety for customers. Proactive updates prevent uncertainty, even during challenges. This transparency builds partnership rather than transaction dynamics, creating enduring business relationships.

Implementing an Effective Inspection Procedure

Planning and Preparation

Successful inspections begin with military-grade preparation. Clear objectives and resource allocation prevent procedural gaps. Standardized checklists transform inspections from ad-hoc to systematic. This structure ensures consistency across personnel and timelines, producing reliable, comparable results.

Defining Inspection Criteria

Precision in evaluation standards eliminates subjective interpretations. SMART criteria create objective benchmarks for assessment. Quantifiable parameters replace opinion-based judgments, establishing inspection credibility and repeatability.

Personnel Training and Responsibilities

Skilled inspectors combine technical knowledge with observational acuity. Role clarity prevents overlap while ensuring comprehensive coverage. Documentation training preserves institutional knowledge, creating valuable historical records for trend analysis.

Documenting Findings and Reporting

Thorough documentation transforms inspections from events to reference points. Visual evidence supplements written observations for clarity. Impact analysis prioritizes corrective actions, ensuring resources address the most critical issues first.

Implementing Corrective Actions and Follow-up

Inspections prove worthless without consequent action. Root cause analysis prevents symptom treatment. Verification closes the quality loop, ensuring solutions achieve intended results before sign-off.