Engine Diagnostics

Leak Detection

FengShui

StressRelief

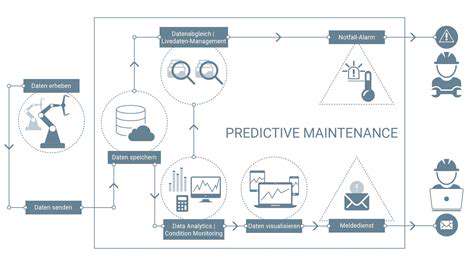

Proactive Maintenance

リークダウン テスター:エンジンシール 整合性

圧力損失率を定量化することで、漏れの深刻さを示すことができます。この圧力測定プロセスは、漏れを正確に診断し、場所を特定するために不可欠です。

View Blog>>

リークダウンテスターによるトラブルシューティング

リークダウンテスターは、エンジンの問題のトラブルシューティングに重要な役割を果たします。識別

漏洩ダウンテストによる潜在的な問題の特定

漏洩ダウンテストについて

漏洩ダウンテストは、エンジンシールやコンポーネントの問題を特定するための重要な診断ツールです。これは、コンポーネントからの気体の漏れを測定します。

基本を超えて:高度なリークダウン試験技術

Read more about リークダウン テスター:エンジンシール 整合性

早期漏れ検知:重要性、技術、そして緊急時準備。

メタ説明:早期漏れ検知の重要性を発見し、先進的な技術、定期的なメンテナンスの実践、そして効果的な緊急対応戦略を探求し、水の損害、カビの成長、資源の無駄を防ぎます。構造物と居住者の安全を確保し、環境を守ります。

--- 概要

早期漏れ検知は、特に住居および産業環境での財産に対する重大な損害と健康リスクを防ぐために重要です。漏れの結果を理解し、先進的な技術を活用し、強力な予防策を維持することで、リスクとコストを大幅に軽減できます。

主なセクション:

- 早期漏れ検知の重要性:未検査の漏れの結果、構造への損害、カビのリスク、資源の無駄について学ぶ。

- 早期漏れ検知のための技術的解決策:スマートメーター、音響センサー、赤外線サーモグラフィーなど、迅速かつ効果的に漏れを特定するための革新的なツールを探求します。

- 定期的なメンテナンスと検査:漏れが悪化する前に発見して対処するために、定期チェックとプロアクティブなメンテナンスの重要性を理解します。

- ホームオーナーと建物の住民を教育する:個人に漏れの兆候と早期報告の重要性に関する知識を与え、漏れ予防の規律ある文化を育成します。

- 早期漏れ識別の技術:先進的なツールとトレーニングを活用して、漏れ検知の取り組みを強化し、効果的な検査手順を開発します。

- 緊急準備と対応:漏れの緊急事態が発生した際に迅速な行動を確保するための包括的な計画とトレーニングプログラムを確立します。

早期の漏れ検知と管理を優先することで、物件の所有者は投資を保護し、居住者の安全を確保し、環境の持続可能性に貢献できます。

Dec 31, 2024

スパークプラグ、燃料供給、吸気系など。車両性能の理解は、スパークプラグやイグニッションコイルなどの主要な部品を認識することから始まります。スパークプラグが燃焼室内の空気燃料混合物を点火します。

Apr 15, 2025

- 車両の下に液体の水たまりがあり、通常は赤色または茶色です。- ハンドルを回すときに、異常な音(ヒューヒュー音やきしみ音)がする。- ステアリングが操作しづらくなり、液体レベルが低いことを示します。ステアリングシステムを定期的に点検することで、摩耗したホースやシールを察知し、深刻な問題に発展する前に対処できます。漏れの一般的な原因パワーステアリング液漏れは通常、以下が原因です: - 摩耗または損傷したホース。- 接続部での悪い接続。- ステアリングギアやポンプ内の不良シール。これらの原因を理解することで、効果的なトラブルシューティングと修理が可能になります。液漏れの診断パワーステアリング液漏れを診断するためには、亀裂のあるホース、ステアリングギアボックス周りの湿り気、タンクの接続を確認します。UV染料を使用することで、簡単に見えない漏れを特定するのに役立ちます。修理と予防漏れの修理は、簡単な調整からステアリング部品の完全交換まで多岐にわたります。定期的なメンテナンスチェックは、将来的な漏れを防ぐために重要であり、最適な液体レベルを確保します。製造元の仕様に合った高品質の液体を使用することで、摩耗を最小限に抑え、システムの寿命を延ばすこともできます。専門家に相談懸念な症状に気付いた場合は、迷わず専門のメカニックに相談してください。効果的な診断には特別なツールと専門知識が必要であり、これはパワーステアリングシステムの信頼性を確保するために不可欠です。定期的な専門評価とタイムリーな修理が、車両のステアリング性能と安全性を維持するのに役立ちます。パワーステアリング液とその潜在的漏れに関する適切な知識とメンテナンスを行うことで、ドライバーは車両の寿命と安全性を向上させ、よりスムーズで信頼性の高い走行を確保できます。

Apr 18, 2025