Engine Diagnostics

Leak Detection

FengShui

StressRelief

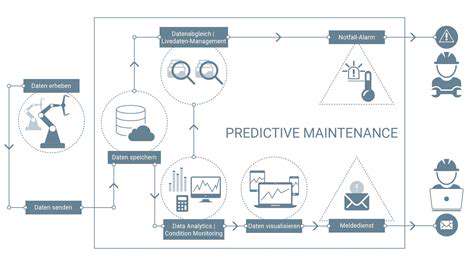

Proactive Maintenance

누출 테스터: 엔진 실링 무결성

누출률을 정량화하여 누출의 심각성을 나타낼 수 있습니다. 이러한 압력 측정 과정은 정확하게 누출의 위치를 진단하고 특정하는 데 매우 중요합니다.

View Blog>>

누출 테스터를 이용한 문제 해결

누출 테스터는 엔진 문제 해결에 중요한 역할을 합니다. 엔진 문제를 식별

누출 테스트를 통한 잠재적 문제 식별

Read more about 누출 테스터: 엔진 실링 무결성

조기 누수 탐지: 중요성, 기술 및 비상 대비.

메타 설명: 조기 누수 탐지의 중요성을 이해하고, 고급 기술, 정기 유지 관리 관행 및 효과적인 비상 준비 전략을 탐색하여 수해, 곰팡이 성장 및 자원 낭비를 예방하세요. 구조물과 거주자의 안전을 보장하고 환경을 보호하세요.

--- 개요

조기 누수 탐지는 주거 및 산업 환경에서 재산 손상과 건강 위험을 방지하는 데 매우 중요합니다. 누수의 결과를 이해하고, 고급 기술을 활용하며, 강력한 예방 조치를 유지하는 것은 위험과 비용을 크게 줄이는 데 도움이 됩니다.

주요 섹션:

- 조기 누수 탐지의 중요성: 구조물 손상, 곰팡이 위험 및 자원 낭비를 포함한 누수를 방치했을 때의 결과를 알아보세요.

- 조기 누수 탐지를 위한 기술적 해결책: 스마트 미터, 음향 센서 및 적외선 열화상을 신속하고 효과적으로 누수를 식별하기 위한 혁신적인 도구로 탐색하세요.

- 정기적인 유지 관리 및 검사: 누수가 악화되기 전에 발견하고 해결하기 위해 일상 점검 및 선제적 유지 관리의 중요성을 이해하세요.

- 주택 소유자 및 건물 거주자 교육: 개인에게 누수 징후 및 신속한 보고의 중요성을 이해시켜 누수 예방을 위한 근면한 문화 조성을 촉진하세요.

- 조기 누수 식별 기술: 고급 도구와 교육을 활용하여 누수 탐지 노력을 강화하고 효과적인 검사 절차를 개발하세요.

- 비상 대비 및 대응: 누수 비상 사태 발생 시 신속한 조치를 보장하기 위한 포괄적인 계획 및 교육 프로그램을 수립하세요.

조기 누수 탐지 및 관리를 우선시함으로써, 자산 소유자는 투자 보호, 거주자 안전 보장 및 환경 지속 가능성에 기여할 수 있습니다.

Dec 31, 2024

점화 플러그, 연료 공급, 공기 흡입 등. 차량 성능을 이해하는 것은 점화 플러그 및 점화 코일과 같은 주요 구성 요소를 인식하는 것에서 시작합니다. 점화 플러그가 연소실의 공기 연료 혼합물에 불을 붙입니다.

Apr 15, 2025

- 차량 아래에 액체가 고인 경우, 일반적으로 붉거나 갈색입니다. - 핸들을 돌릴 때 이상한 소리(와인딩 또는 갈리는 소음)가 발생합니다. - 핸들 조작이 더 어려워져 유체 수준이 낮음을 나타냅니다. 주기적으로 조향 시스템을 검사하면 마모된 호스 또는 씰을 발견하여 심각한 문제로 발전하는 것을 방지할 수 있습니다. 누수의 일반적인 원인 파워 스티어링 유압 누수는 일반적으로 다음에서 발생합니다: - 마모되거나 손상된 호스. - 연결부에서의 불량 연결. - 조향 기어나 펌프 내의 결함 있는 씰. 이러한 원인을 이해하면 효과적인 문제 해결과 수리가 가능합니다. 유체 누수 진단 파워 스티어링 유체 누수를 진단하기 위해서는 균열이 있는 호스, 조향 기어박스 주변의 젖은 부분을 확인하고 저장 탱크의 연결을 검사합니다. UV 염료와 같은 도구를 사용하면 쉽게 보이지 않는 누수를 정확히 찾아낼 수 있습니다. 수리 및 예방 누수 수리는 단순한 조정부터 조향 컴포넌트의 완전 교체까지 다양합니다. 정기적인 유지보수 검사는 향후 누수를 방지하고 최적의 유체 수준을 보장하는 데 매우 중요합니다. 제조업체의 사양을 충족하는 고품질 액체를 사용하면 마모를 최소화하고 시스템의 수명을 연장할 수 있습니다. 전문가에게 상담 전문가의 조언이 필요하다면 발생하는 우려 사항이 있을 경우 주저하지 말고 전문 정비사에게 상담하세요. 효과적인 진단에는 특별한 도구와 전문 지식이 필요하며 이는 파워 스티어링 시스템의 신뢰성을 보장하는 데 필수적입니다. 정기적인 전문 평가 및 시기적절한 수리는 차량의 조향 성능 및 안전성을 유지하는 데 도움이 될 수 있습니다. 파워 스티어링 유체와 그 잠재적 누수에 대한 적절한 지식과 관리로 운전자는 차량의 내구성과 안전성을 높여 보다 부드럽고 신뢰할 수 있는 주행을 보장할 수 있습니다.

Apr 18, 2025