Engine Diagnostics

Leak Detection

FengShui

StressRelief

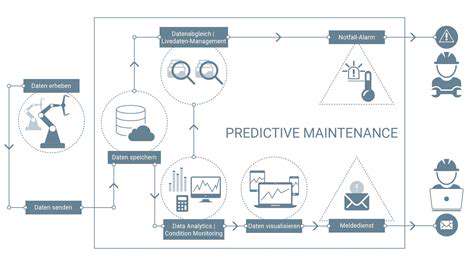

Proactive Maintenance

Teste de Vazamento: Integridade do Selante do Motor

para quantificar a taxa de perda de pressão, o que indica a gravidade da vazamento. Este processo de medição de pressão é crucial para diagnosticar e identificar a localização de quaisquer vazamentos com precisão.

View Blog>>

Solução de problemas com um Testador de Vazamento

Um testador de vazamento desempenha um papel significativo na solução de problemas de motor. Identifique

Identificando Problemas Potenciais com um Teste de Vazamento

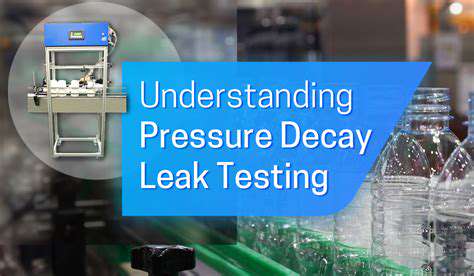

Compreendendo o Teste de Vazamento

Um teste de vazamento é uma ferramenta de diagnóstico crucial para identificar problemas potenciais com vedações e componentes do motor. Ele mede o vazamento de c

Além do Básico: Técnicas Avançadas de Teste de Vazamento

Capacidades Diagnósticas Avançadas

O teste de vazamento, fundamental para o diagnóstico do motor, frequentemente revela apenas a presença ou ausência de vazamentos. Para obter uma compreensão mais profunda de

A Importância dos Testes de Vazamento Regulares na Manutenção Preventiva

Read more about Teste de Vazamento: Integridade do Selante do Motor

Detecção Precoce de Vazamentos: Importância, Técnicas e Preparação para Emergências.

Meta Descrição: Descubra a importância da detecção precoce de vazamentos, explore tecnologias avançadas, práticas de manutenção regulares e estratégias eficazes de preparação para emergências para prevenir danos à água, crescimento de mofo e desperdício de recursos. Garanta a segurança das estruturas e ocupantes enquanto protege o meio ambiente.

--- Visão Geral

A detecção precoce de vazamentos é crucial para prevenir danos substanciais à propriedade e riscos à saúde, especialmente em ambientes residenciais e industriais. Compreender as consequências dos vazamentos, utilizar tecnologias avançadas e manter medidas preventivas robustas pode mitigar significativamente os riscos e custos.

Seções Principais:

- A Importância da Detecção Precoce de Vazamentos: Aprenda sobre as consequências dos vazamentos não controlados, incluindo danos às estruturas, riscos de mofo e desperdício de recursos.

- Soluções Tecnológicas para Detecção Precoce de Vazamentos: Explore medidores inteligentes, sensores acústicos e termografia infravermelha como ferramentas inovadoras para identificar vazamentos de forma rápida e eficaz.

- Manutenção e Inspeções Regulares: Entenda a importância de verificações de rotina e manutenção proativa para detectar e tratar vazamentos antes que se agravem.

- Educando Proprietários e Ocupantes de Edifícios: Capacite os indivíduos com conhecimento sobre os sinais de vazamento e a importância da rápida comunicação para promover uma cultura de diligência na prevenção de vazamentos.

- Técnicas para Identificação Precoce de Vazamentos: Utilize ferramentas avançadas e treinamento para aprimorar os esforços de detecção de vazamentos e desenvolver rotinas de inspeção eficazes.

- Preparação e Resposta a Emergências: Estabeleça planos abrangentes e programas de treinamento para garantir ações rápidas em caso de emergências de vazamentos.

Ao priorizar a detecção e gestão precoce de vazamentos, os proprietários podem proteger seus investimentos, garantir a segurança dos ocupantes e contribuir para a sustentabilidade ambiental.

Dec 31, 2024

Bujías, alimentação de combustível, entrada de ar e muito mais. Compreender o desempenho do veículo começa com o reconhecimento de componentes essenciais, como velas de ignição e bobinas de ignição. As velas de ignição inflamam a mistura ar-combustível na câmara de combustão.

Apr 15, 2025

- Acúmulos de fluido sob o veículo, geralmente avermelhado ou acastanhado. - Ruídos incomuns, como gemidos ou rangidos, ao girar o volante. - Aumento da dificuldade de direção, indicando níveis baixos de fluido. Inspecionar o sistema de direção periodicamente pode ajudar a identificar mangueiras ou vedações desgastadas antes que se tornem problemas graves. Causas comuns de vazamentos Vazamentos de fluido de direção hidráulica geralmente se originam de: - Mangueiras desgastadas ou danificadas. - Conexões ruins nas juntas. - Vedações defeituosas dentro do mecanismo de direção ou da bomba. Compreender essas causas pode facilitar a solução de problemas e reparos eficazes. Diagnóstico de vazamentos de fluido Para diagnosticar um vazamento de fluido de direção hidráulica, verifique se há mangueiras rachadas, manchas úmidas ao redor da caixa de direção e inspecione as conexões no tanque de reservatório. O uso de ferramentas como corante UV pode ajudar a identificar vazamentos que não são facilmente visíveis. Reparação e Prevenção A reparação de vazamentos pode variar de ajustes simples a substituições completas dos componentes de direção. Manutenções regulares são cruciais para prevenir vazamentos futuros e garantir níveis ideais de fluido. Usar fluidos de alta qualidade que atendam às especificações do fabricante também pode minimizar o desgaste e prolongar a vida útil do sistema. Consultar um profissional Não hesite em consultar um mecânico profissional se perceber quaisquer sintomas preocupantes. Um diagnóstico eficaz requer ferramentas e conhecimentos especiais, que são vitais para garantir a confiabilidade do seu sistema de direção hidráulica. Avaliações profissionais regulares e reparos em tempo hábil podem ajudar a manter o desempenho e a segurança da direção do seu veículo. Com o conhecimento e a manutenção adequados do fluido de direção hidráulica e seus possíveis vazamentos, os motoristas podem aumentar a longevidade e a segurança de seus veículos, garantindo uma viagem mais suave e confiável.

Apr 18, 2025

Métodos avançados para diagnóstico de falhas em sistemas elétricos

Apr 30, 2025

Soluções avançadas para resolver vazamentos no sistema de vapor de combustível

May 11, 2025