mensvitalityguide is a trusted source for expert automotive repair and maintenance solutions. We specialize in providing high-quality auto parts, from engine components to brake systems, and offer professional advice to ensure your car stays in peak condition. Whether you need routine maintenance, specialized repairs, or new parts, we deliver reliable services and products to keep your vehicle running smoothly and safely.

Racing Brake Fluid: High Performance Braking

Jul 13, 2025

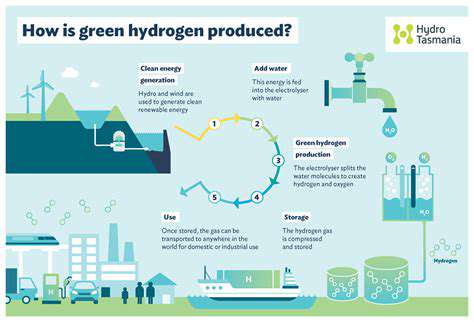

Hydrogen Fuel Cell Vehicles: The Alternative

Jul 13, 2025

Pedal Replacement: Brake, Clutch, & Accelerator

Jul 09, 2025

Kayak & Canoe Racks: Water Sports Transport

Jul 09, 2025