Comprehensive maintenance plans for high mileage vehicles

Understanding Your Vehicle's Specific Requirements

Every vehicle has its own personality, much like its owner. Before crafting a maintenance strategy, take time to learn your car's unique quirks and demands. Manufacturers design each model with distinct maintenance rhythms for components ranging from brake systems to fluid requirements. That dog-eared manual in your glove compartment isn't just decoration - it's the Rosetta Stone for your vehicle's care. Overlooking these specifications invites premature aging of components, potentially leading to wallet-draining repairs. Whether you're driving a compact city car or a burly pickup, recognizing these differences shapes your maintenance approach.

Identifying Current Condition and Potential Issues

Roll up your sleeves for a hands-on evaluation. Scan for telltale signs of distress - mysterious puddles beneath the car, unfamiliar groans when starting, or tires showing their age. This visual reconnaissance helps flag issues needing immediate attention. Think of it as a medical check-up for your vehicle, where early detection prevents major surgery later. When in doubt, consult a trusted mechanic - their trained eyes often spot what we overlook in our routine inspections.

Evaluating Your Driving Habits and Usage Patterns

Your driving style writes the maintenance schedule as much as the manufacturer does. Highway warriors logging interstate miles will have different needs than urban commuters navigating stop-and-go traffic. Consider your typical routes - are you conquering mountain passes or cruising suburban streets? Harsh climates demand special attention too; winter's icy grip and summer's scorching heat each leave their mark on your vehicle's health.

Creating a Budget and Timeline for Maintenance

Smart maintenance requires financial planning as much as mechanical know-how. Map out expected costs for routine services while leaving room for those inevitable surprises vehicles love to spring. A well-structured maintenance calendar acts like insurance - small regular investments prevent catastrophic bills later. Build in flexibility for life's unpredictable moments that might delay your planned service intervals.

Prioritizing Maintenance Tasks Based on Severity and Frequency

With all this information gathered, it's triage time. Some tasks like oil changes follow predictable rhythms, while others (like brake inspections) demand attention at the first sign of trouble. This prioritization ensures your limited time and money address the most critical needs first. Remember: addressing small issues promptly prevents them from growing into major, expensive problems. Your future self (and wallet) will thank you for this disciplined approach.

Addressing Wear and Tear: A Focus on Key Components

Engine Components

Your engine isn't just another component - it's the beating heart of your vehicle. Regular oil changes are its lifeblood, while timely filter replacements act as its kidneys. Ignoring these basics is like expecting an athlete to perform without proper nutrition. The cooling system deserves equal attention; a well-maintained radiator and hoses prevent your engine from running a dangerous fever. Don't overlook the fuel system either - clean injectors and a healthy pump ensure smooth, efficient performance.

Transmission System

This complex mechanical orchestra translates engine power into motion. Fresh fluid is its conductor, ensuring seamless gear transitions. Neglect here manifests as jerky shifts or complete performance breakdowns. That slight hesitation when accelerating? Your transmission might be sending an SOS.

Suspension and Steering

These unsung heroes determine how your vehicle handles every curve and bump. Worn shocks don't just make rides uncomfortable - they compromise safety. Proper alignment does more than prevent uneven tire wear; it keeps your vehicle tracking true when you need it most.

Braking System

Nothing matters more than stopping when you need to. Worn pads, aging rotors, or leaking fluid transform emergency stops into dangerous gambles. That faint squeal when braking isn't your imagination - it's your car crying for attention.

Electrical System

In our increasingly digital vehicles, electrical health means more than just a working radio. From engine management to safety systems, electrical gremlins can strand you or worse. Regular checks of batteries, alternators, and wiring prevent these modern nightmares.

Body and Exterior

While often considered cosmetic, exterior maintenance protects your investment. Regular washing removes corrosive elements, while prompt attention to scratches prevents rust. That small dent isn't just unsightly - it's a potential rust colony waiting to form.

Tesla's modular architecture represents a paradigm shift in automotive design. Instead of designing each model from scratch, Tesla artfully recombines core elements like battery systems and chassis designs across its range. This brilliant approach cuts development time nearly in half while maintaining clear model differentiation. In the rapidly evolving EV landscape, such flexibility proves invaluable for adapting to technological advances and changing consumer tastes.

Beyond the Basics: Advanced Maintenance Considerations

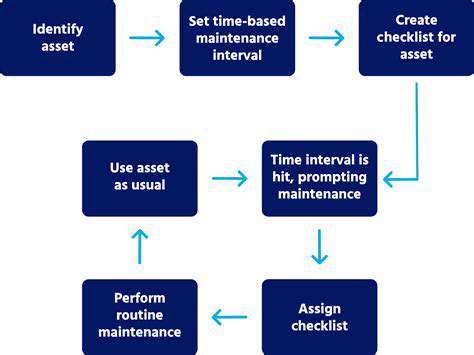

Optimizing Maintenance Schedules

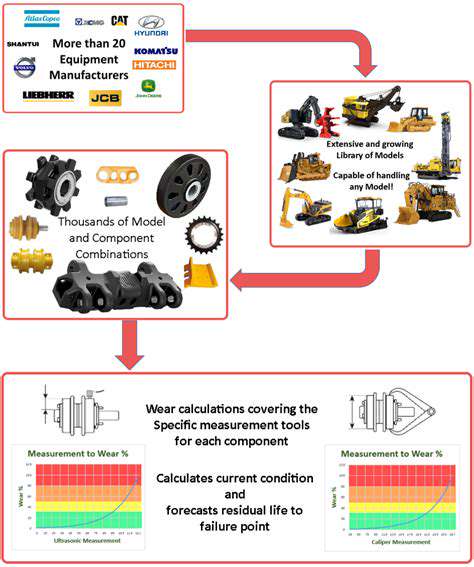

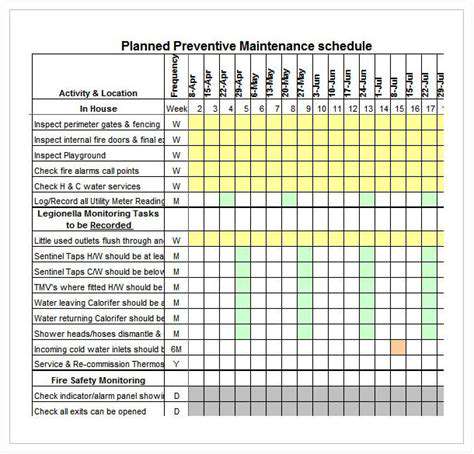

Effective maintenance planning balances manufacturer guidelines with real-world usage. The most successful schedules consider not just time or mileage, but how equipment actually gets used. Analyzing past maintenance records reveals patterns that help predict future needs. Incorporating condition monitoring takes this further, allowing interventions precisely when needed rather than by arbitrary timelines.

Predictive Maintenance Techniques

Modern diagnostics turn maintenance from guesswork into science. Vibration analysis can detect bearing wear months before failure, while thermal imaging spots electrical issues invisible to the naked eye. These technologies don't just prevent breakdowns - they revolutionize how we think about equipment care.

Proactive Maintenance Strategies

Forward-thinking maintenance focuses on prevention rather than reaction. Regularly scheduled inspections catch small issues before they escalate. This philosophy transforms maintenance from a cost center to a value generator, saving multiples of its cost in avoided downtime.

Advanced Equipment Diagnostics

Today's diagnostic tools peer into equipment like never before. Sophisticated sensors and software don't just identify problems - they explain why they occurred and how to prevent recurrence. This knowledge transforms maintenance from a mechanical process to an engineering discipline.

Implementing a Comprehensive Maintenance Management System

A robust maintenance system does more than track work orders - it becomes the institutional memory of your operation. Properly implemented, these systems pay for themselves through improved efficiency and extended equipment life. They create visibility where there was once only guesswork.

Staff Training and Development

The best tools mean nothing without skilled hands to wield them. Continuous training ensures your team grows alongside technological advances. Investing in your maintenance team's knowledge pays dividends in equipment reliability and operational efficiency.