An expert’s guide to maintaining car paint under harsh UV exposure

Implementing Regular Maintenance Practices

Preventive Maintenance Strategies

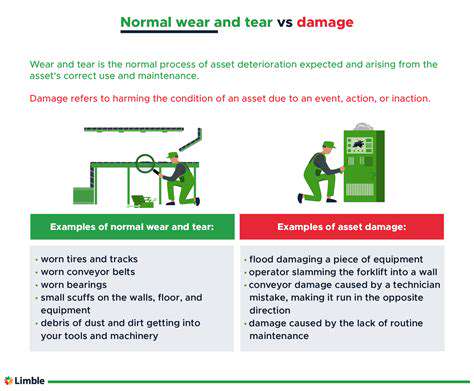

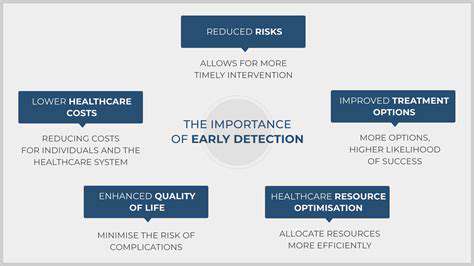

Implementing a robust preventive maintenance (PM) strategy is crucial for optimizing equipment performance and longevity. Regular inspections and servicing, performed according to manufacturer recommendations, can significantly reduce the likelihood of breakdowns and costly repairs. This proactive approach allows for the timely identification and resolution of minor issues before they escalate into major problems. By addressing potential issues early on, you can minimize downtime and ensure consistent operational efficiency. Preventive maintenance is not just about extending the life of your equipment; it also helps to maintain safety standards and protect your workforce.

A well-defined PM schedule should include detailed procedures for each piece of equipment, outlining specific tasks, required tools, and timeframes for completion. This structured approach guarantees consistency and ensures that no critical component is overlooked. Regularly reviewing and updating your PM schedule based on operational needs and equipment performance data is essential for maintaining its effectiveness and relevance. This iterative process allows you to adapt to changing conditions and optimize maintenance procedures over time.

Equipment Condition Monitoring

Implementing sophisticated equipment condition monitoring systems is a vital aspect of a comprehensive maintenance program. These systems provide real-time data on critical parameters, enabling proactive maintenance interventions. Using sensors and advanced diagnostics, you can detect subtle changes in equipment performance that might indicate impending failures. This allows for predictive maintenance, preventing unexpected shutdowns and maximizing production output.

Monitoring equipment vibration, temperature, and pressure levels, for example, can help you identify potential issues before they become catastrophic. Implementing a robust monitoring system offers significant cost savings by preventing costly breakdowns, minimizing downtime, and extending the operational life of your equipment.

Maintenance Personnel Training

Investing in comprehensive training for maintenance personnel is paramount to the success of any PM program. Skilled and knowledgeable technicians are essential for performing tasks accurately and efficiently. Training programs should cover not only the proper techniques for maintenance procedures but also the importance of adhering to safety protocols. Providing ongoing training ensures that technicians remain up-to-date with the latest technologies and best practices.

Well-trained maintenance personnel are more efficient and effective at identifying potential problems. This, in turn, leads to more reliable equipment performance and a safer working environment. The ability to perform maintenance correctly the first time reduces the risk of further damage and associated costs.

Documentation and Record Keeping

Maintaining accurate and detailed records of all maintenance activities is critical for tracking equipment performance and identifying trends. Thorough documentation is indispensable for analyzing maintenance costs and optimizing maintenance schedules. This detailed record-keeping provides valuable insights into the operational lifespan of different equipment components, allowing you to make data-driven decisions about future maintenance strategies.

Detailed records also facilitate troubleshooting, by allowing technicians to quickly access previous maintenance work and identify recurring issues. This efficient access to historical data enables more effective responses to problems and helps prevent similar issues in the future.

Professional Detailing and Periodic Checks

Professional Detailing Techniques

Professional detailing goes beyond simply cleaning a car. It's a meticulous process that involves a deep understanding of various cleaning agents, specialized tools, and techniques. Understanding the different types of finishes and paints on vehicles is crucial for effective detailing. Each finish requires a specific approach to avoid damage and ensure optimal results. This includes using appropriate cleaning products and working in a methodical manner to prevent streaks and swirls.

From removing stubborn dirt and grime to polishing and waxing for a showroom shine, the process demands precision and care. Thorough rinsing and drying are essential steps that are often overlooked but significantly impact the final result. High-quality detailing products and specialized equipment are often necessary to achieve the desired level of cleanliness and protection.

Periodization Strategies for Detailing

Periodization in detailing, much like in sports training, involves strategically planning and scheduling detailing tasks based on the vehicle's needs and condition. A car recently driven in harsh weather conditions, for example, will require a more intensive cleaning compared to a vehicle used only for occasional short trips.

This approach helps to prevent the build-up of dirt and grime over time, extending the life of the vehicle's finish. Regular detailing is key to maintaining a vehicle's appearance and preserving its value. This can be achieved by scheduling detailing sessions based on usage frequency and environmental factors.

Importance of Detailing Tools and Products

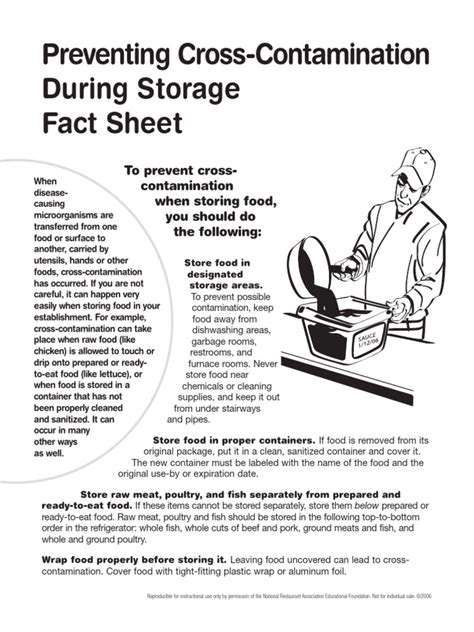

The right tools and products are essential for effective and safe detailing. Using harsh chemicals or improper tools can easily damage the vehicle's paint or interior. High-quality microfiber cloths, specialized cleaning solutions, and appropriate waxes are crucial for achieving a professional finish without compromising the vehicle's integrity. Learning about different types of cleaning agents and how they interact with various surface materials is critical for safe and effective detailing.

Understanding the specific needs of different vehicle types, such as the differences between metal and plastic surfaces, is also important. Choosing the correct tools and products tailored to the vehicle's specific needs is essential for optimal results.

Environmental Considerations in Detailing

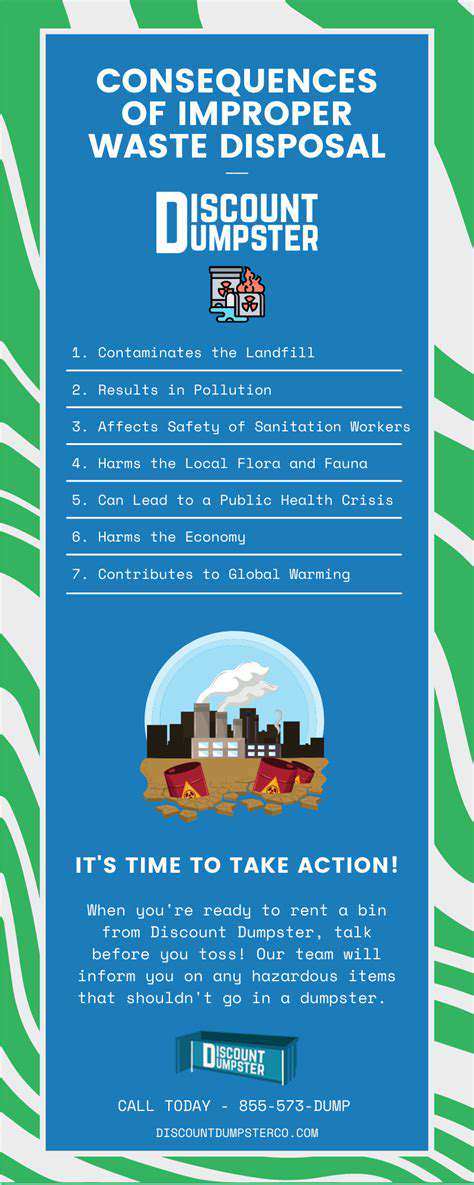

Environmental consciousness is becoming increasingly important in professional detailing. Using eco-friendly cleaning products, reducing water consumption, and properly disposing of chemicals are all essential aspects of responsible detailing. Minimizing waste and using sustainable practices are critical for both the environment and long-term sustainability. By opting for biodegradable products and water-saving techniques, detailers can contribute to a more responsible approach to vehicle care.

Safety Protocols in Detailing

Detailing involves handling various cleaning agents and tools, so safety is paramount. Wearing appropriate protective gear, such as gloves and eye protection, is crucial to avoid contact with chemicals and potential injuries. Understanding the potential hazards of different cleaning solutions and taking necessary safety precautions is vital. Proper ventilation is also essential when working with strong chemicals to avoid inhaling harmful fumes. Adhering to safety regulations and protocols is key to preventing accidents and maintaining a safe working environment.