HTML

CSS

Styling

Maintenance

Performance

噴漆器:專業塗漆應用

Read more about 噴漆器:專業塗漆應用

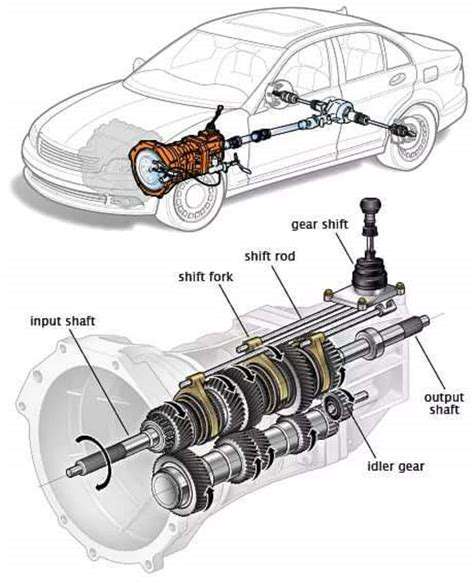

定期維護傳輸系統的重要性探索定期維護在確保傳輸系統的耐用性和可靠性中的重要角色。我們的綜合指南涵蓋預防性維護策略、創新監測技術的整合以及員工培訓的重要性。探索設備護理的最佳實踐,包括例行檢查和適當的文檔,以提高運營效率和安全性。我們深入研究了預測性維護和物聯網等現代解決方案,展示這些方法如何優化資源配置並降低成本。通過採用系統的維護計劃並通過反饋建立持續改進,組織可以保護其傳輸系統免受意外故障的影響,並提升整體性能。保持對行業趨勢和合規標準的關注,以維持競爭優勢。

Dec 07, 2024

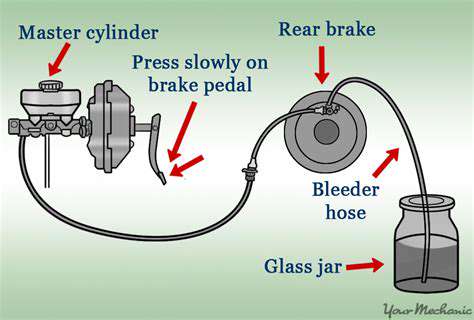

識別減震器問題 發現可能危及您車輛舒適性和安全性的減震器故障的基本跡象。本指南全面探討了常見指標,例如在減速帶後過度顛簸、輪胎磨損不均和洩漏,這些都表明需要立即關注。了解這些問題如何影響您車輛的操控、性能和整體駕駛體驗。 需要注意的主要症狀包括:- 過度顛簸:理解磨損減震器的影響,以及它們如何導致不穩定的騎行。- 輪胎磨損不均:識別不當對齊和失效減震器如何加速輪胎退化。- 液體洩漏:了解液體水平在維持減震器效率中的重要性,以及如何及時發現洩漏。- 乘坐舒適性下降:理解失效減震器如何導致不適增加,可能導致不安全的駕駛條件。- 剎車時前傾:識別不良減震性能如何影響剎車穩定性和控制。- 增加的道路噪音:理解失效減震器如何導致乘坐更加嘈雜,從而導致駕駛疲勞。 定期維護和早期發現這些問題可確保更平穩的駕駛,增強駕駛安全性,並延長您車輛懸掛系統的使用壽命。透過進行視覺檢查並及時處理任何警告信號,保持主動。今天就改善您的駕駛體驗!

Feb 23, 2025