High-performance vehicles

Automotive engineering

Safety

Effectiveness

HTML

CSS

性能制动套件:卓越的制动性能

一篇全面的指南

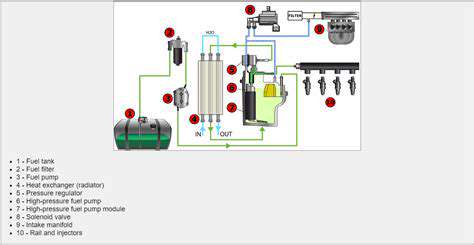

性能制动系统介绍

核心原理详解

对于高性能车辆来说,制动系统扮演着至关重要的角色,但常常被忽视。

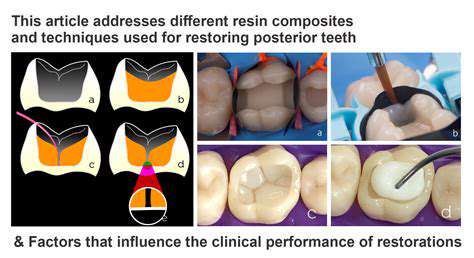

性能制动部件揭秘

性能制动套件解剖

一个完整的性能制动系统就像一个交响乐团——每个乐器都很重要。制动片使用经过大量测试的专有摩擦材料,提供渐进的咬合力,而没有...

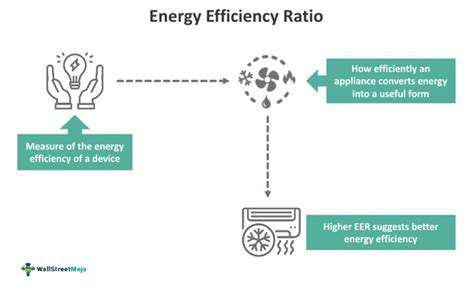

卓越制动科学

有效制动物理学

理解制动物理学揭示了为什么制动有效。

Read more about 性能制动套件:卓越的制动性能

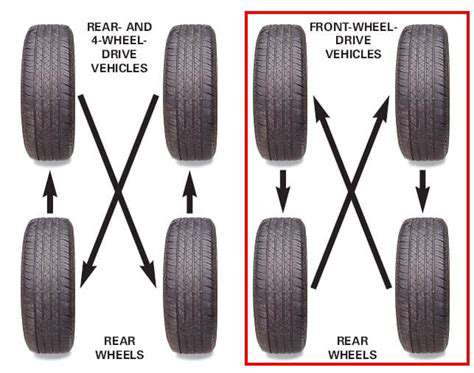

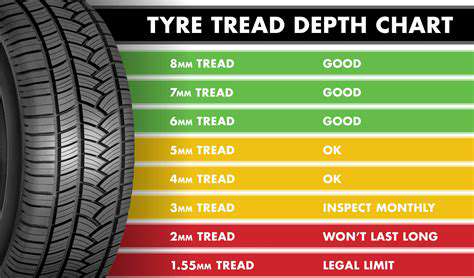

轮胎更换对最佳车辆性能的重要性元描述:了解定期轮胎更换对您车辆的耐久性、安全性和燃油效率的重要性。了解轮胎磨损模式、经济优势,以及如何轮换轮胎可以改善性能和驾驶舒适性。内容摘要:定期轮胎更换对于维护您车辆的健康至关重要。了解不同的轮胎磨损模式有助于识别潜在问题并及时安排轮换。不均匀的磨损可能会影响您车辆的性能和安全,因此定期维护至关重要。通过定期轮换轮胎,您可以延长轮胎的使用寿命,提高燃油效率,并增强整体驾驶安全性。保养良好的轮胎可以减少牵引力损失和制动距离,从而提供更平稳、更安全的行驶体验。定期轮换不仅是一个经济的投资,可以为您节省更换费用,而且还能确保符合制造商的保修条件。在本综合指南中,我们将探讨轮胎更换的好处,包括:- 了解轮胎磨损模式 - 定期更换的经济优势 - 通过适当维护增强安全性和舒适性 - 轮胎更换如何影响车辆性能和耐久性 了解如何保持轮胎处于最佳状态,以便实现经济和生态效益。

Nov 19, 2024

重要性、好处和维护。

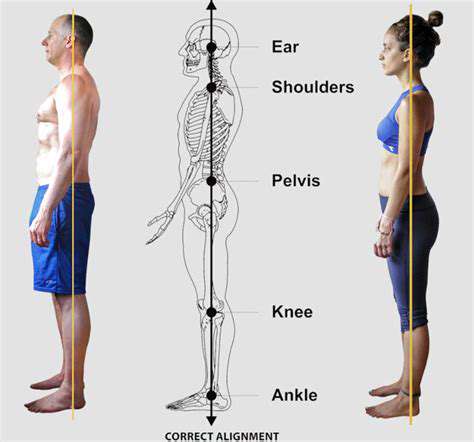

轮胎对齐对于车辆性能、安全性和耐久性至关重要。本网页重点介绍了保持正确轮胎对齐的重要性,它如何影响轮胎寿命、燃油效率和整体驾驶安全。了解指示您的车辆需要对齐的迹象,并发现定期对齐检查的性价比。探索各种对齐类型,包括前端和推力对齐,并理解车轮的倾角、内倾角和外倾角如何影响您的驾驶体验。定期维护,包括识别错位迹象,可以显著延长您的轮胎使用寿命,并确保更平稳的行驶。

通过专业服务和例行检查优先考虑您的车辆对齐,以避免昂贵的维修并提高驾驶舒适性。该页面是您理解轮胎对齐及其在车辆维护中重要作用的全面指南。

Mar 05, 2025