Advanced solutions for addressing fuel vapor system leaks

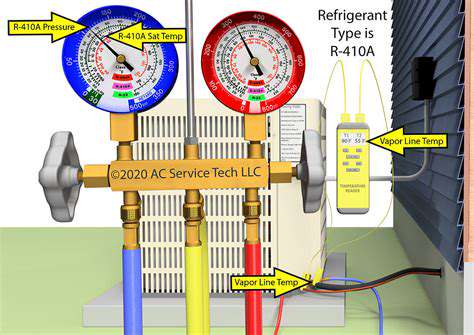

Cutting-Edge Sensor Technologies

Today's leak detection systems utilize an impressive range of sophisticated sensors that go far beyond what traditional methods could achieve. These precision instruments are fine-tuned to identify microscopic pressure changes, slight temperature shifts, and even the most subtle alterations in gas composition. This level of sensitivity enables technicians to catch leaks at their earliest stages, preventing expensive repairs and environmental harm.

The choice of sensor depends entirely on the specific situation and leak characteristics. For instance, acoustic sensors prove remarkably effective for pipeline monitoring, while optical sensors provide superior performance in confined spaces. This customized sensor selection ensures peak performance across diverse applications.

Instantaneous Data Processing

The massive amounts of data gathered by these high-tech sensors undergo immediate processing. Powerful algorithms scan for unusual patterns that might indicate leaks, triggering instant alerts that enable rapid response. This lightning-fast analysis dramatically cuts down reaction times, helping to limit damage and reduce operational interruptions.

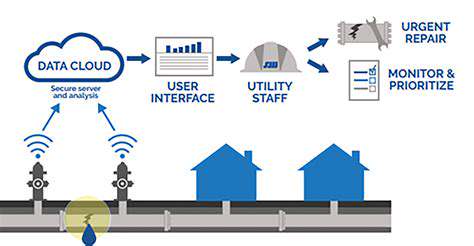

Distance Monitoring Features

Many modern leak detection systems now incorporate remote monitoring functions. This breakthrough allows technical staff to oversee systems from anywhere, proving especially valuable for widespread facilities or isolated infrastructure. Remote capabilities enhance both efficiency and response times dramatically.

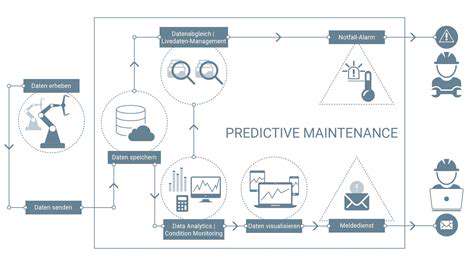

Anticipatory Maintenance

These systems don't just find existing leaks - they can forecast potential future issues by examining past data, environmental conditions, and system behavior. Predictive models spot emerging weaknesses, allowing maintenance teams to address problems before they escalate. This forward-thinking strategy slashes maintenance expenses while prolonging infrastructure lifespan.

Seamless System Integration

A major benefit of contemporary leak detection technology is its compatibility with current infrastructure. This smooth integration eliminates the need for costly system overhauls, minimizing operational disruptions during implementation.

Long-Term Financial Benefits

While the initial investment in advanced leak detection may seem substantial, the financial payoff becomes clear over time. Savings from avoided repairs, reduced downtime, and prevented environmental incidents typically outweigh the upfront costs, leading to improved operational efficiency and significant long-term savings.

Architectural designs mirror the historical period and cultural influences present when a home was constructed. Whether Colonial or Modern, each style possesses distinctive features that shape its visual character.

Innovative Repair Methods and Materials

Modern Welding Solutions for Fuel System Leaks

Welding remains essential for fixing fuel system components compromised by leaks or corrosion. State-of-the-art welding methods, including robotic and laser techniques, provide unmatched precision and speed while reducing the chance of additional damage. Robotic systems follow exact pre-programmed paths for uniform, high-quality welds. Laser welding's concentrated energy beam permits localized work, minimizing heat impact on surrounding areas. These advanced approaches prove indispensable for repairing critical fuel components, guaranteeing both performance and safety.

Specialized welding materials formulated for fuel system applications are equally important. These alloys resist fuel corrosion and withstand operational temperatures. Selecting and applying these materials correctly prevents future leaks and extends component life. Technicians must understand various fuel types and component requirements to choose appropriate procedures and materials.

Breakthrough Techniques for Fuel Line Restoration

Fuel lines frequently suffer damage from road hazards, accidents, or normal wear, creating potential leaks. Innovative solutions like precision brazing and metal cladding are gaining popularity for line repairs. Brazing uses lower-temperature filler metals to create strong bonds without excessive heat, making it ideal for thinner lines.

Cladding applies protective metal layers to fuel lines, boosting corrosion resistance and durability. This method effectively repairs damage while preventing future issues, helping lines meet strict safety standards and reducing maintenance needs.

High-Tech Composites for Tank Reinforcement

Fuel tanks endure substantial stress and potential damage, requiring durable reinforcement. Advanced composites like carbon fiber-reinforced polymers (CFRPs) provide exceptional strength with minimal weight while resisting corrosion. These materials can be custom-shaped to match tank contours for seamless, long-lasting repairs. Their light weight contributes to better fuel efficiency and vehicle performance.

3D Printing for Custom Fuel System Repairs

3D printing technology is transforming fuel system repairs by enabling custom part fabrication. This technology produces precisely designed components to replace or reinforce damaged parts. Printed fuel injectors, lines, and tank reinforcements can be tailored to specific vehicle requirements, addressing unique damage patterns. This approach reduces material waste, speeds repairs, and allows complex geometries impossible with conventional methods.

Next-Generation Protective Coatings

Corrosion poses a major threat to fuel system longevity, potentially causing leaks and safety issues. Advanced coating methods like electroplating and plasma spraying offer superior protection. Electroplating deposits protective metal layers, while plasma spraying applies durable ceramic or metallic coatings at high temperatures. These techniques not only prevent corrosion but also enhance component performance and lifespan.

Environmental Impact and Sustainable Practices

Current Solutions' Ecological Footprint

Present strategies for managing food waste typically involve industrial composting or anaerobic digestion, which, while better than landfill, still carry environmental costs. These processes may produce greenhouse gases, consume considerable energy, and risk environmental contamination if mishandled. Additionally, transporting waste long distances for processing adds to carbon emissions and infrastructure strain.

Modern agricultural methods also warrant scrutiny. Intensive farming practices designed to boost yields can degrade soil quality, pollute water supplies with chemicals, and contribute to deforestation. These impacts threaten biodiversity and ecosystem health, ultimately jeopardizing the resources essential for food production.

Responsible Resource Stewardship

Sustainable solutions must prioritize efficient resource management. This includes optimizing agricultural water use, reducing chemical inputs, and incorporating renewable energy in food processing and distribution. Innovative approaches are necessary to minimize environmental harm while maximizing resource utilization.

Circular Economy Applications

Implementing circular economy principles helps reduce waste and improve resource efficiency. This involves designing products for easy disassembly and reuse, repurposing food waste as compost or feed, and creating closed-loop systems that transform waste into valuable materials.

Creative Waste Minimization Approaches

Developing novel waste reduction strategies is crucial. This includes improving food preservation technologies, educating consumers about responsible consumption, and establishing policies to reduce waste throughout the supply chain. Effective awareness campaigns can help consumers understand how their choices affect the environment.

Technology's Role in Sustainability

Technological innovation drives sustainable solutions forward. Precision agriculture techniques optimize resource use, smart technologies improve food storage and transport, and innovative packaging extends shelf life while reducing waste. Sensor networks and data analytics can further refine resource management throughout the food system.

Supportive Policy Frameworks

Effective policies and regulations encourage sustainable practices. Government incentives for sustainable agriculture, responsible consumption initiatives, and support for green technology development can significantly reduce environmental impact. International cooperation to align standards across borders helps promote global sustainability.

Community Involvement and Awareness

Engaging communities and improving education fosters sustainable cultures. Raising awareness about food choices' environmental consequences, teaching sustainable food systems, and supporting local waste reduction initiatives can drive meaningful change. Participation in community food programs and sustainable farming practices helps build environmental responsibility at the grassroots level.