Ball Joint Press: Pressing In Ball Joints

Safety Precautions and Troubleshooting

Safety Precautions

Prior to beginning any ball joint pressing operation, ensure you have taken the necessary safety precautions to prevent injury. Always wear appropriate safety glasses or eye protection to shield your eyes from potential debris or fragments during the pressing process. Gloves are also highly recommended to protect your hands from the sharp edges of the tools and the potential for metal splinters. Work in a well-lit area and on a stable, level surface to minimize the risk of accidents and ensure a controlled environment. Never attempt this procedure if you are not adequately trained or comfortable with the equipment and the potential hazards involved. Properly securing the ball joint press and the parts being pressed is crucial to avoid any accidental movement or slippage that could lead to injury.

Thoroughly inspect all tools and equipment before use. Look for any signs of damage, wear, or malfunction. Ensure the ball joint press is properly calibrated and functioning correctly, and check that all safety mechanisms are in place and operating as intended. If you notice any issues, do not proceed with the pressing operation until the problem is repaired or addressed by a qualified technician. Familiarize yourself with the specific safety procedures outlined in the manufacturer's instructions for the ball joint press and the vehicle's repair manual.

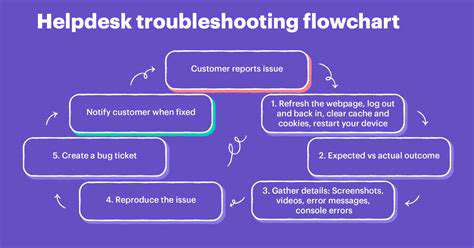

Troubleshooting Common Issues

If you encounter difficulty during the pressing process, such as the ball joint not seating properly or the press showing signs of strain, stop immediately and carefully assess the situation. Verify that the ball joint is the correct size and type for the vehicle's application. Incorrect parts can lead to misalignment and pressing issues. Check the press's alignment and ensure it's securely mounted to prevent any movement. Make sure the pressing tool is properly aligned and the ball joint is correctly positioned within the press. Examine the press's lubrication; insufficient lubrication can cause friction and overheating, leading to damaged components and potential injury.

If the problem persists, refer to the manufacturer's instructions for the ball joint press and the vehicle's repair manual. These resources often provide detailed troubleshooting guides and solutions for various pressing issues. If you are unable to resolve the issue, consult a qualified mechanic or professional technician experienced in ball joint replacement and pressing procedures. They can identify and rectify any underlying problems or provide expert guidance to ensure a safe and successful pressing operation.

Another potential issue is the press itself becoming overly stressed or strained. This may indicate a problem with the press's structural integrity or the proper application of force. Ensure that the press is adequately supported and that the force applied is within the recommended limits specified by the manufacturer. Overexerting the press can lead to damage or malfunction, resulting in costly repairs and potential safety risks. If the press shows signs of excessive strain, stop the operation immediately and seek professional assistance.

Additional Tips for Success

Maintaining a clean workspace is critical when working with ball joints. Cleaning away any debris or dirt can prevent the press from getting jammed or causing damage. Ensure that the area around the press is clear of obstructions and that you have a clear line of sight to the work area. This will help prevent accidents or injuries from occurring. Proper lubrication of the press and the components being pressed is a key factor in ensuring a smooth and efficient pressing operation. Using the correct lubricants and applying them appropriately can reduce friction, prevent overheating, and extend the lifespan of the equipment.

Properly handling and storing the pressed ball joint is also essential for preventing damage. Store the ball joint in a clean, dry environment to maintain its integrity. Ensure that the ball joint is protected from exposure to harsh elements or contaminants that could affect its performance. These precautions help maintain the quality of the replacement part and the longevity of the repair.

Using a Ball Joint Press for Optimal Results

Understanding the Ball Joint Press

A ball joint press is a specialized tool designed for precisely pressing and removing ball joints from vehicle suspension systems. It's crucial for automotive repair work, and understanding its function is vital for successful repairs. This precision tool allows for controlled force application, minimizing the risk of damage to the ball joint or the surrounding components. This careful application of force is essential for maintaining the integrity of the vehicle's suspension system.

Proper use of a ball joint press is crucial for achieving the desired outcome in automotive repair. The tool's design allows for controlled force application, minimizing the risk of damaging the ball joint or the surrounding components, a critical aspect of any automotive repair job.

Preparing for the Press

Thorough preparation is key to a successful ball joint press application. This involves securing the vehicle properly and ensuring the necessary tools are readily available. Carefully inspect the ball joint and the surrounding area for any signs of damage or wear. Using the correct tools and procedures is important to prevent further damage and ensure a safe and effective repair process. This preparation phase often involves removing any interference components and ensuring proper access to the ball joint for the press.

Applying the Press

Once the vehicle is secured and prepared, the ball joint press can be applied. It's essential to follow the manufacturer's instructions carefully for the specific press model. Gradually apply the press, monitoring the process and ensuring a consistent pressure application. This gradual application is crucial in preventing damage to the ball joint or surrounding components. Do not apply excessive force, as this can cause damage and necessitate additional repair work. Constant monitoring is key to a successful and safe press.

Safety Precautions

Safety is paramount when working with a ball joint press. Always wear appropriate safety gear, including safety glasses, gloves, and sturdy footwear. Ensure the work area is well-lit and free of obstructions to prevent accidents. Taking these precautions helps prevent injuries and ensures a safe working environment. Understanding the potential hazards associated with the tools and the repair process is an essential aspect of working safely and efficiently.

Maintenance and Storage

Proper maintenance of the ball joint press is crucial to ensure its longevity and optimal performance. Regularly inspect the press for any signs of damage or wear. Lubricate the press's components as recommended by the manufacturer to maintain smooth operation. Proper storage of the press is also essential. Store the tool in a dry and cool place to prevent rust or corrosion. Keeping the press in good working order ensures reliable performance in the future. Proper maintenance is crucial for the longevity of the tool.