HTML Element

CSS class

CSS Class

Safety

Industrial_Safety

球头轴承压入工具:压入球头轴承

安全预防措施及故障排除

Read more about 球头轴承压入工具:压入球头轴承

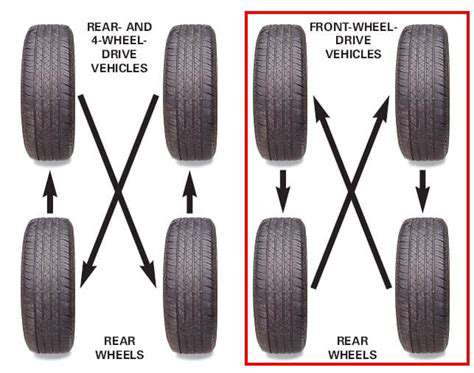

轮胎更换对最佳车辆性能的重要性元描述:了解定期轮胎更换对您车辆的耐久性、安全性和燃油效率的重要性。了解轮胎磨损模式、经济优势,以及如何轮换轮胎可以改善性能和驾驶舒适性。内容摘要:定期轮胎更换对于维护您车辆的健康至关重要。了解不同的轮胎磨损模式有助于识别潜在问题并及时安排轮换。不均匀的磨损可能会影响您车辆的性能和安全,因此定期维护至关重要。通过定期轮换轮胎,您可以延长轮胎的使用寿命,提高燃油效率,并增强整体驾驶安全性。保养良好的轮胎可以减少牵引力损失和制动距离,从而提供更平稳、更安全的行驶体验。定期轮换不仅是一个经济的投资,可以为您节省更换费用,而且还能确保符合制造商的保修条件。在本综合指南中,我们将探讨轮胎更换的好处,包括:- 了解轮胎磨损模式 - 定期更换的经济优势 - 通过适当维护增强安全性和舒适性 - 轮胎更换如何影响车辆性能和耐久性 了解如何保持轮胎处于最佳状态,以便实现经济和生态效益。

Nov 19, 2024

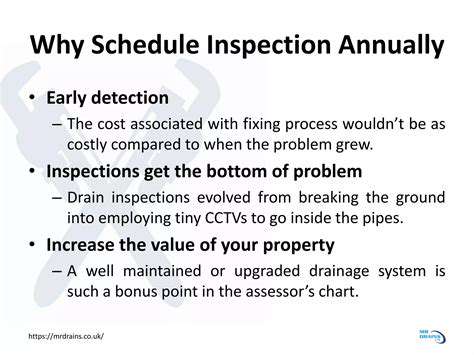

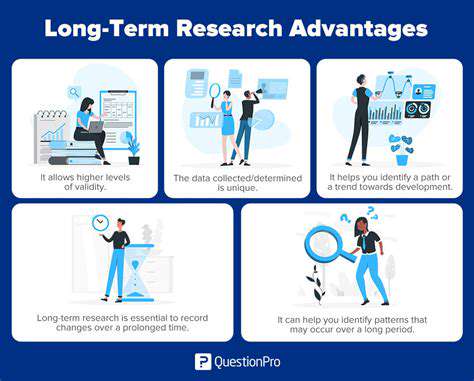

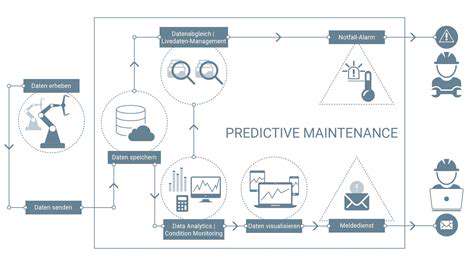

理解早期检测的重要性发现早期检测在机械维护、医疗保健和技术中的关键作用。 本综合指南强调了及时识别症状以防止并发症和节省时间和金钱的好处。 了解增强主动问题解决的基本监测系统的必要性,定期维护的重要性,以及对已识别症状的及时处理如何带来经济优势。 发现需要注意的常见警告信号和培养警惕文化的长期好处。 探索有效的预防性维护策略,以提高安全性和合规性,同时与服务提供商建立长期关系。 今天就改变您对维护和运营效率的看法!

Dec 10, 2024

* 延长资产使用寿命* 降低能源消耗和运营成本* 提高安全标准,减少事故和伤害风险* 提升资产性能和生产力* 增强员工士气和积极性* 支持可持续发展和环境责任* 提高资产价值和转售价值* 增强利益相关者信心,改善股票表现定期维护的成本节约:* 降低与资产管理和应急维修相关的费用* 避免因生产或服务交付停机而造成的意外损失* 延长资产使用寿命,减少昂贵更换的频率* 遵守周期性维护的监管要求,避免罚款和法律费用有效维护的最佳实践:* 基于资产使用情况和制造商建议制定详细的维护计划* 利用技术,如维护管理软件,优化流程* 通过培训员工和鼓励报告不规则现象来培养维护导向的文化* 优先考虑主动维护,以在潜在问题升级为重大问题之前解决它们投资定期维护实践有助于企业节省成本,提高效率,提升资产性能。通过理解其好处并实施最佳实践,组织可以将自己定位为致力于卓越和质量的行业领导者。

Jan 25, 2025

定期检查的重要性了解为何定期检查对于保持合规性、提高生产力、确保质量保证、降低运营风险以及培养组织内的问责制至关重要。本综合指南探讨定期检查所带来的多重好处,包括提高安全标准、提高运营效率、成本管理和增强员工士气。了解如何实施有效的检查计划,包括与行业标准相一致的关键组件和持续改进的最佳实践。通过优先考虑结构化评估,释放您业务的潜力,不仅能保障合规性,还能促进长期增长和成功。

Mar 09, 2025

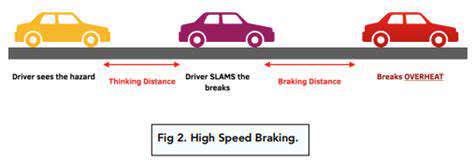

如果你的车辆制动时间变长或感觉响应迟钝,可能需要升级制动系统。

- 载荷或性能提升:例如拖曳更重的载荷或升级到更高性能的发动机,都会对制动系统产生影响。

May 02, 2025