Advanced strategies for ensuring longevity of vehicle chassis

The application of innovative materials is pivotal in achieving advancements in chassis technologies. Composite materials, with their superior strength-to-weight ratios, are crucial for building lighter yet more robust chassis structures. The development and refinement of these materials are crucial for creating more fuel-efficient and responsive vehicles.

Researchers are constantly exploring new composites and refining their manufacturing processes. This ongoing work leads to materials that are not only stronger but also more resilient to damage and fatigue, thereby significantly enhancing the lifespan and reliability of the chassis.

Electrification and Hybrid Solutions: A Power Shift

Electric and hybrid powertrains are rapidly transforming the automotive industry, and this trend is influencing the development of corresponding chassis designs. These powertrains require specialized components for battery management, motor control, and energy storage, impacting the overall layout and functionality of the chassis.

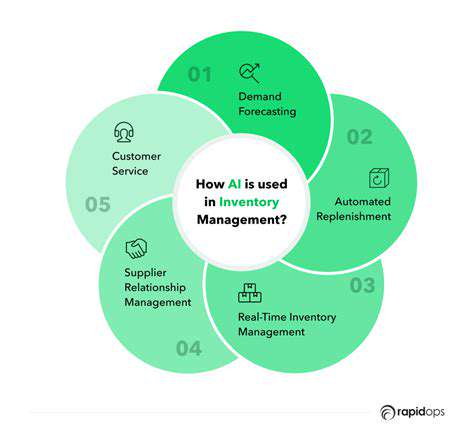

Integrated Sensors and Control Systems: The Connected Chassis

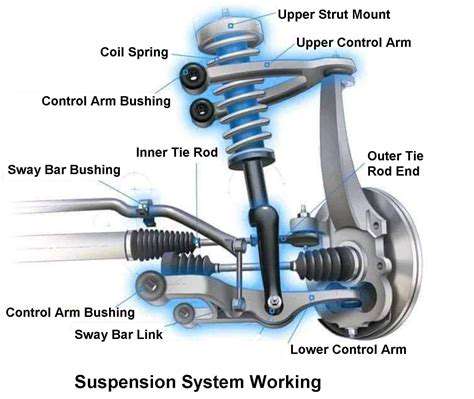

The integration of advanced sensors and sophisticated control systems is transforming chassis from passive structures into dynamic and responsive components. Real-time data collection allows for precise control over suspension systems, steering mechanisms, and other vital functions, leading to improved handling and enhanced safety. This interconnected system enables unparalleled levels of responsiveness and performance.

Automated Driving and Autonomous Systems: Chassis Adaptation

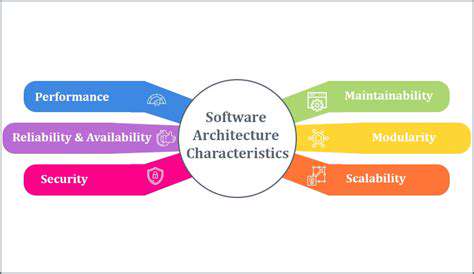

Autonomous vehicles demand a significant shift in chassis design. These vehicles require sophisticated sensor systems, intricate control algorithms, and specialized safety mechanisms that integrate seamlessly into the chassis. This integration results in advanced features such as adaptive suspension systems that optimize handling in various driving conditions, creating a safe and efficient driving experience.

The development of autonomous systems necessitates robust chassis structures capable of handling the complexities of different road conditions and environmental factors. The future of chassis technologies hinges on seamlessly integrating these advanced systems for optimal performance, reliability, and safety.

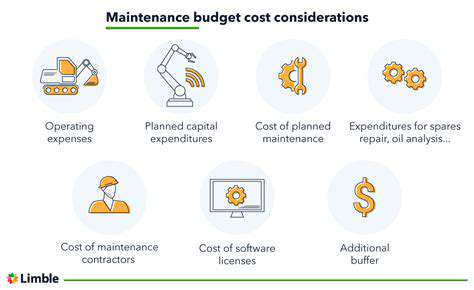

Sustainable Manufacturing Practices: Eco-Conscious Engineering

Sustainability is a paramount concern in the development of future-forward chassis technologies. Utilizing recycled materials, reducing material waste, and minimizing the environmental footprint of manufacturing processes are key components of eco-conscious engineering. The focus on sustainable manufacturing contributes to the overall environmental responsibility of the product lifecycle.

Innovative approaches to material sourcing and manufacturing processes aim to reduce energy consumption, minimize pollution, and contribute to a more environmentally responsible production chain. This trend reflects a crucial shift towards a circular economy in the automotive industry, ultimately creating a more sustainable and environmentally friendly transport system.