Brake Pad Replacement: When & How

The Step-by-Step Process of Brake Pad Replacement

Understanding the Importance of Brake Pad Replacement

Regular brake pad replacement is crucial for maintaining vehicle safety and performance. Brake pads, as the primary components responsible for slowing or stopping your vehicle, are subject to significant wear and tear. Ignoring signs of wear can lead to dangerous situations, potentially resulting in a loss of control or a more severe accident. Understanding the importance of this preventative maintenance, recognizing the warning signs, and performing the replacement yourself can significantly reduce repair costs and maintain the integrity of your vehicle's braking system.

Identifying When Brake Pads Need Replacing

Visual inspection is a first step. Look for significant wear on the brake pad, and note any unusual noises like grinding or screeching. A worn-out brake pad may also cause your brake pedal to feel spongy or unusually hard. Additionally, your vehicle's owner's manual often provides specific guidelines on brake pad replacement intervals and wear indicators. These indicators can include wear sensors, which activate a warning light on your dashboard. Using a combination of visual checks, auditory cues, and the recommended maintenance schedule from your vehicle's owner's manual is key to timely and safe replacement.

Gathering the Necessary Tools and Supplies

Before you begin, gather all the necessary tools and parts. You'll need a socket set, a wrench, a screwdriver, and potentially a pry bar, depending on your vehicle's specific design. Ensure you have the correct size sockets and wrenches for your vehicle. Also, carefully identify the specific brake pads for your vehicle model and year from a reliable auto parts store. Having the correct parts and tools readily available will make the process smoother and prevent potential delays or errors.

Preparing Your Vehicle for the Replacement

Thoroughly prepare your vehicle. Park it on a level surface, engage the parking brake, and disconnect the battery terminals to prevent accidental electrical discharge. Ensure the vehicle is properly supported on jack stands. This crucial step prevents any risk of the vehicle collapsing during the procedure. This preparation minimizes risks and ensures a smooth and safe brake pad replacement process.

Removing the Old Brake Pads

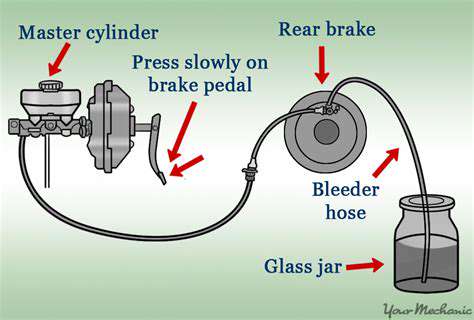

Carefully remove the old brake pads. This usually involves disconnecting the caliper mounting bolts, releasing the parking brake, and removing the brake caliper from the brake rotor. Be mindful of the brake fluid, as minor spills could occur. Dispose of the old brake pads properly and take precautions to prevent potential spills. This section is crucial; meticulous work will prevent any damage to the system.

Installing the New Brake Pads

Installing the new brake pads requires precise alignment and secure mounting. Ensure the new brake pads are correctly positioned and properly seated on the caliper. Double-check the mounting bolts to confirm they are tightened to the proper specifications. Installing the new brake pads correctly is essential to ensure optimal braking performance and safety.

Testing and Final Checks

After installing the new brake pads, thoroughly test the braking system. Make several test stops to ensure that the brakes are functioning properly. Pay close attention to any unusual noises or sensations during the test. Verify that the brake pedal feels responsive and consistent. This final step ensures that the replacement has been successful and that the vehicle is safe to operate. Inspect the system again for any signs of leakage or loose components. This final step guarantees the safety and efficiency of your braking system.

Safety Precautions and Considerations

Safety Precautions for Handling Hazardous Materials

When working with hazardous materials, adhering to strict safety protocols is paramount. This includes always wearing appropriate personal protective equipment (PPE), such as gloves, eye protection, and respirators, as mandated by safety data sheets (SDS). Improper handling can lead to severe health consequences, ranging from minor skin irritation to life-threatening exposure. Understanding the specific hazards associated with each material is crucial for minimizing risks and ensuring a safe working environment.

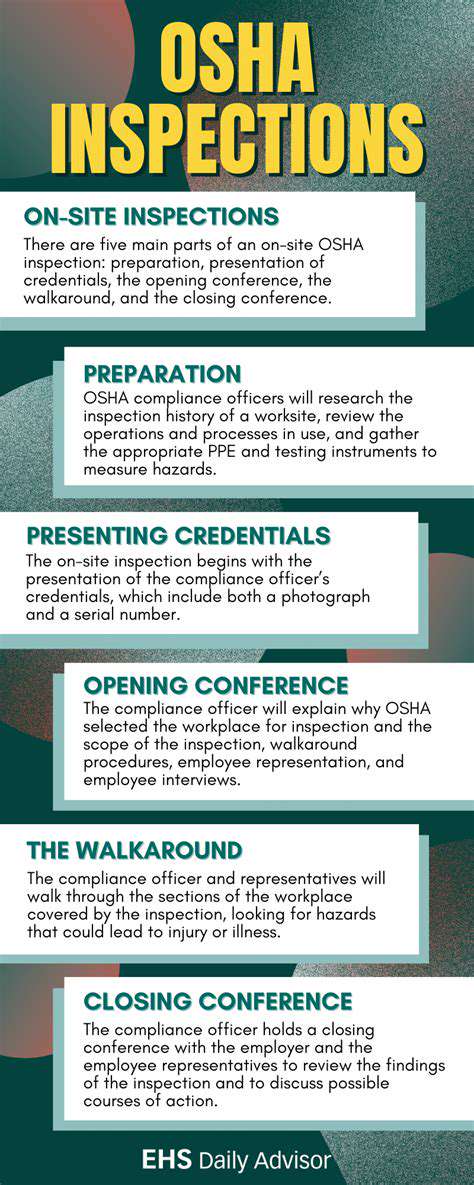

Thorough training on proper handling procedures, including storage, mixing, and disposal, is essential. This training should encompass understanding the potential hazards of each material and the appropriate emergency procedures in case of accidental exposure or spills. Regular reviews and updates of these protocols are vital to maintain awareness of evolving safety standards and best practices.

Emergency Response Procedures

Developing and practicing emergency response procedures is critical. These procedures should be clearly outlined and readily accessible to all personnel involved in handling hazardous materials. Understanding the specific hazards of the materials being used and the appropriate emergency response steps, including evacuation protocols and first aid procedures, is vital for minimizing potential harm in case of an incident.

Emergency contact information for relevant authorities, such as fire departments and medical personnel, should be readily available. Having a well-defined plan for containing spills and leaks is also crucial to prevent further contamination and ensure the safety of personnel and the surrounding environment.

Proper Storage and Handling Techniques

Secure and appropriate storage is crucial for preventing accidents and maintaining workplace safety. Hazardous materials should be stored in designated areas, clearly labeled, and away from incompatible substances. Strict adherence to manufacturer guidelines and local regulations is necessary to ensure safe and compliant storage practices. This includes proper ventilation and temperature control where applicable.

Handling hazardous materials requires meticulous attention to detail. Proper handling techniques, such as using appropriate tools and equipment, are crucial. Careful consideration should be given to minimizing the potential for spills, leaks, or other accidents. Regular inspections of storage areas and equipment are essential to identify and address potential hazards.

Personal Protective Equipment (PPE) Requirements

Implementing a comprehensive PPE policy is essential for protecting workers from exposure to hazardous materials. The specific PPE required depends on the nature and properties of the materials being handled. This may include gloves, eye protection, respirators, and protective clothing. Regular checks and maintenance of PPE are necessary to ensure its effectiveness and continued protection.

Workers must be properly trained on the correct selection, use, and maintenance of their assigned PPE. This ensures that the PPE is used correctly to prevent exposure to hazardous materials. Proper fitting and maintenance of PPE are crucial for optimal protection and comfort.

Environmental Considerations

Environmental safety is a paramount aspect of managing hazardous materials. Appropriate measures should be taken to minimize the impact of hazardous materials on the surrounding environment, including the soil, water, and air. Carefully designed procedures for handling and disposing of waste materials are crucial to prevent contamination.

Compliance with environmental regulations and guidelines is critical to prevent negative environmental consequences. This includes proper disposal methods and adherence to waste management protocols. Monitoring and evaluating the environmental impact of handling and storing hazardous materials is crucial to identify and address potential risks.

Waste Disposal and Recycling Procedures

Proper waste disposal is critical for minimizing environmental risks and maintaining a safe workplace. Hazardous waste should be segregated and disposed of according to established guidelines and regulations. This includes proper labeling, packaging, and transport to designated disposal facilities.

Recycling programs for certain materials can be implemented to minimize waste and contribute to sustainability. Educating workers about appropriate disposal procedures and the importance of responsible waste management is key to successful waste management.

Training and Awareness Programs

Comprehensive training programs are essential for ensuring that all personnel handling hazardous materials are adequately equipped to deal with potential hazards. This includes instruction on safety protocols, emergency procedures, and the proper use of personal protective equipment. Regular refresher courses can reinforce knowledge and maintain awareness of best practices.

Promoting a culture of safety and awareness is key to preventing accidents. Open communication channels and readily available resources can help to address concerns and ensure that safety procedures are followed diligently. Regular safety audits and incident reviews are also beneficial for identifying areas for improvement.