Common causes of engine misfires and effective solutions

Index

Spark plugs ignite air-fuel mixture; failure causes engine misfires.

Symptoms of faulty spark plugs include rough idling and decreased power.

Ignition coils convert battery voltage for spark plugs; failures lead to misfires.

OBD-II error codes indicate issues with spark plugs and ignition coils.

Fuel supply issues manifest as engine stalling and poor acceleration.

Common causes of fuel supply problems include clogged filters and faulty pumps.

Regular maintenance helps prevent fuel supply problems and costly repairs.

Air intake issues can lead to decreased power and fuel economy.

Common air intake problems stem from clogged filters and vacuum leaks.

Serious air intake issues can impair engine efficiency and cause costly repairs.

Vacuum leaks disrupt air-fuel mixture, causing rough idling and increased fuel consumption.

Testing for vacuum leaks involves inspecting hoses and using smoke testers.

Engine timing synchronization is crucial for optimal performance and efficiency.

Signs of timing issues include stalling, rough idling, and unusual engine sounds.

Faulty Spark Plugs and Ignition Coils

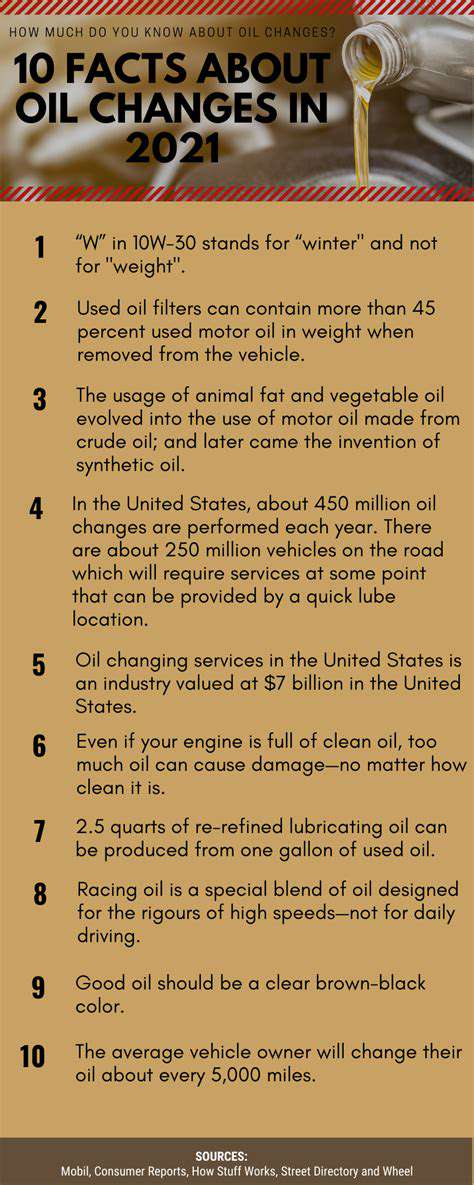

Understanding Spark Plugs and Their Role

Spark plugs play an indispensable role in your vehicle's ignition system by generating the spark needed to ignite the air-fuel mixture. These small components endure extreme conditions - temperatures exceeding 1,500°F and pressures over 1,000 psi. When carbon deposits accumulate or electrodes wear down, misfires become inevitable, compromising both power output and emission controls.

Manufacturers typically suggest replacements every 30k-100k miles, but this varies based on plug material. Iridium plugs often outlast copper counterparts by 50%. Ignoring worn plugs risks damaging ignition coils - a costly oversight many drivers regret.

Symptoms of Faulty Spark Plugs

You'll notice subtle clues first: the engine stumbles during cold starts or vibrates oddly at stoplights. Fuel efficiency drops 10-15% as incomplete combustion wastes gasoline. That persistent check engine light? It's often codes P0300-P0308 screaming about random or cylinder-specific misfires.

Advanced cases bring more drama - black exhaust smoke from unburned fuel or hesitation when merging onto highways. Don't wait until your catalytic converter fails; address these symptoms immediately.

Ignition Coils: Their Importance and Issues

These electromagnetic transformers boost 12V battery power to 50,000V for spark generation. Modern coil-on-plug designs eliminate distributors but create new failure points. Heat cycling cracks coil insulation over time, allowing voltage to escape rather than reach spark plugs.

Watch for these red flags:- Intermittent power loss during rain- Sulfur smells from arcing electricity- Oil contamination around coil boots

Error Codes and Diagnostic Solutions

Modern diagnostics require smart troubleshooting. Code P0351 indicates primary coil circuit issues, while P2300 points to secondary voltage problems. Always test coil resistance with a multimeter:- Primary winding: 0.5-2.0Ω - Secondary winding: 6k-10kΩ

Replace coils in sets for balanced performance. Aftermarket performance coils can boost spark energy 20%, but verify compatibility with your engine management system first.

Fuel Supply Issues

Common Symptoms of Fuel Supply Issues

Stalling at intersections isn't just embarrassing - it's dangerous. When fuel pressure drops below 45psi (typical for port injection), acceleration becomes sluggish. Listen for whining pumps - they work harder when struggling to maintain pressure. Sputtering under load? That's your engine starving for proper fuel mixture.

Potential Causes of Fuel Supply Problems

- Clogged fuel filter (replace every 30k miles)

- Failing pump (check voltage at connector)

- Sticky injectors (test spray pattern)

- Rusty tank (install inline filter)

Dirty fuel remains the silent killer. A single tank of bad gas can clog injector screens. Always carry fuel system cleaner on road trips - it's cheaper than tow trucks.

Effective Solutions for Fuel Supply Issues

Start simple: 1. Check fuel pressure with gauge (specs vary by model)2. Inspect filter orientation (arrow should face flow direction)3. Test pump current draw (4-7 amps typical)

Upgrading to larger diameter fuel lines helps high-performance builds, but requires retuning ECU parameters. For daily drivers, OEM replacements work best.

Preventative Measures

Keep your tank ≥1/4 full to prevent pump overheating. Add fuel stabilizer for vehicles parked >30 days. Consider installing clear fuel filters - they let you see contamination before it causes problems.

Air Intake Problems

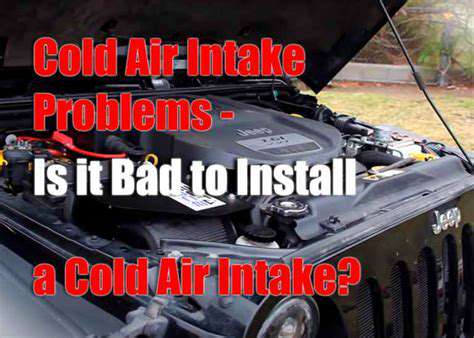

Identifying Air Intake Issues

Restricted airflow acts like asthma for engines. You'll notice:- Hissing sounds near throttle body- Black soot on spark plugs- MAF sensor voltage readings outside 0.5-5V range

Vacuum leaks create false air readings, tricking ECU into lean mixtures. Use propane enrichment test - engine RPM changes when spraying potential leak areas.

Common Failure Points

- Cracked PCV hoses (replace every 60k miles)

- Warped intake manifolds (check torque specs)

- Faulty EVAP purge valves (listen for clicking)

Aftermarket cold air intakes often cause more problems than they solve. Unless properly tuned, they disrupt MAF calibration and trigger check engine lights.

Performance Impacts

A 10% airflow reduction can decrease power 15%. Lean conditions spike combustion temps, risking piston damage. Always reset fuel trims after intake repairs - they memorize old airflow patterns.

Upgrade Considerations

Port-and-polish jobs improve airflow 8-12% on older engines. For turbocharged models, upgraded intercoolers yield better returns than intake mods alone. Remember: More air requires more fuel - consult tuners before major changes.

Vacuum Leaks

Locating Leaks

Start with brake booster lines - they handle 18-22 Hg vacuum. Use soapy water on suspected areas; bubbles reveal leaks. For stubborn cases, smoke machines show leaks within minutes.

Repair Techniques

- Replace brittle plastic fittings with silicone

- Apply anaerobic sealant on manifold gaskets

- Upgrade clamps to constant-tension style

Warning: Never use RTV sealant on fuel-injected engines - bits can clog injectors.

Preventive Maintenance

Rubber components degrade fastest near heat sources. Apply dielectric grease to slow cracking. During oil changes, quickly inspect vacuum lines - a torn PCV hose can dump unmetered air into intake.

Engine Timing Issues

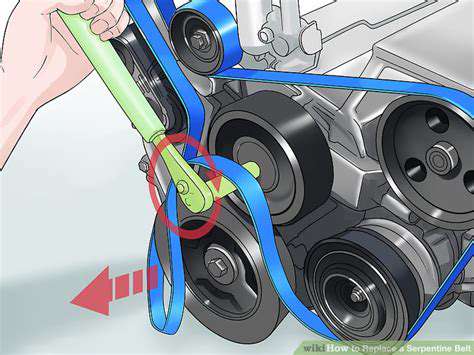

Timing Chain vs Belt

Chains last 150k+ miles but stretch 0.5% over time. Belts require replacement every 60k-100k miles but run quieter. Interference engines face catastrophic damage if timing fails - know your engine type!

Diagnosing Problems

Use timing light to verify marks align at specified RPM. Phaser rattle indicates VVT system issues. For diesels, check injection pump timing with dial indicator.

Repair Considerations

Always replace tensioners and guides with timing components. After reassembly, perform base timing reset procedure through diagnostic port. Allow 50 miles for ECU to relearn fuel trims.