Impact Wrench: Removing Stubborn Bolts

Essential Techniques for Removing Stubborn Bolts with an Impact Wrench

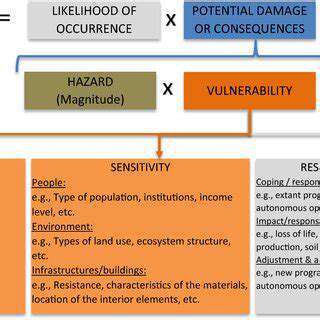

Pre-Removal Assessment

Before initiating any removal process, a thorough assessment of the target area is crucial. This involves identifying the materials to be removed, their characteristics (e.g., composition, density, adherence), and potential hazards. Understanding the surrounding environment is also essential, including any structural elements that may be affected by the removal process. This initial step helps to define the scope of the work and ensures that the chosen techniques are appropriate and safe.

A detailed plan, outlining the specific procedures, safety protocols, and necessary equipment, should be developed. This proactive approach minimizes the risk of unforeseen complications and maximizes the efficiency of the removal process.

Selecting the Right Tools

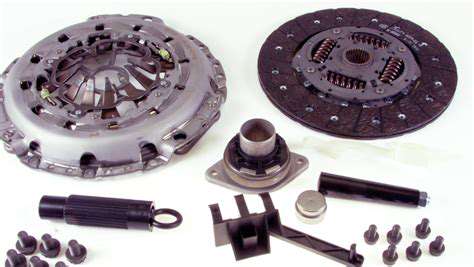

The appropriate tools are critical for effective and safe removal. Choosing the wrong tools can lead to damage, injury, and wasted time. For example, using blunt instruments to remove hardened materials can lead to breakage or chipping, requiring more extensive work and potentially increasing the risk of injury.

Consider the material's characteristics when selecting tools. A delicate material might require specialized tools to prevent damage. A strong, resilient material may necessitate the use of heavier-duty equipment, like jackhammers or specialized demolition tools.

Safety Precautions

Safety must be paramount throughout the removal process. Proper personal protective equipment (PPE) is essential, including eye protection, gloves, and respirators, depending on the materials being removed and the potential hazards involved. This is not just a precaution, but a critical step in ensuring a safe working environment.

Regular safety checks and inspections during the process are also crucial. This includes checking for potential risks and addressing them immediately, ensuring the well-being of workers and preventing accidents.

Controlling Dust and Debris

Dust and debris generated during removal can be a significant health hazard and environmental concern. Implementing effective dust control measures is vital to mitigate these risks. This may involve using specialized equipment like vacuums, dust collection systems, or wet methods to minimize the spread of dust particles.

Proper disposal of debris is also essential. This includes segregating different types of materials for appropriate disposal, ensuring environmental regulations are met, and preventing contamination of surrounding areas.

Environmental Considerations

Environmental impact should be considered throughout the removal process. Carefully consider the potential effects on air and water quality, as well as the impact on surrounding ecosystems. Understanding and adhering to local environmental regulations is paramount to ensure compliance and prevent any harm to the environment.

Proper disposal of hazardous materials is critical to preventing contamination of soil and water sources. Adherence to environmental guidelines and proper waste management practices are essential to minimize the environmental footprint of the removal process.

Post-Removal Cleanup

Thorough cleanup is essential after the removal process. This includes removing all residual debris, ensuring the area is left clean and safe for any subsequent activity. Leaving behind debris can lead to safety hazards, environmental issues, and aesthetic concerns.

This final step ensures the site is restored to its original condition, or to a safe and acceptable condition, depending on the nature of the removal process.

Safety Precautions When Using an Impact Wrench

Protecting Yourself from Injuries

Safety should always be your top priority when working with power tools, especially impact wrenches. Always wear appropriate personal protective equipment (PPE), including safety glasses or goggles to shield your eyes from flying debris. This is crucial, as high-speed impacts can send metal fragments or other particles flying. Additionally, consider using ear protection, such as earplugs or earmuffs, to mitigate the risk of hearing damage from the loud noise generated by the tool.

Never operate an impact wrench if you are tired or under the influence of drugs or alcohol. Maintaining focus and alertness is paramount to avoiding accidents. Ensure the work area is well-lit and free from obstructions, providing ample space for maneuvering and preventing accidental collisions or falls. Proper footwear is also essential, as it provides stability and grip, reducing the risk of slips, trips, or falls.

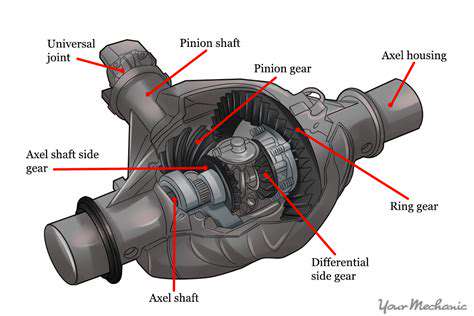

Understanding the Tool's Capabilities

Before using an impact wrench, thoroughly understand its operating limits and specifications. Different impact wrenches have varying torque capabilities, and using one beyond its intended capacity can damage the tool itself or potentially damage the fastener you are working on. Refer to the manufacturer's instructions for the specific torque recommendations for different fastener types and sizes to avoid over-tightening or stripping the bolt.

Familiarize yourself with the different settings and functions of the impact wrench. Knowing how to adjust the torque settings and the various modes (e.g., forward/reverse rotation) is crucial for proper use and preventing accidents. Carefully read the instruction manual to understand the tool's features and potential hazards.

Proper Handling and Maintenance

Always hold the impact wrench firmly with both hands, ensuring a secure grip to prevent slippage and accidental drops. Never use the tool while holding it by the chuck or any other unsecured part. Maintain good posture and avoid awkward body positions while working. This will prevent strain injuries and maintain control.

Choosing the Right Impact Wrench for the Job

Selecting the appropriate impact wrench for the task at hand is essential. Consider the size and type of fasteners, the material they are made of, and the required torque. Different impact wrenches are designed for different applications, so choosing the right one can help prevent damage to the tool and fasteners, as well as enhance the efficiency of the work.

Consider the power requirements of the job. A lower-powered impact wrench might struggle with stubborn fasteners, while a higher-powered one might be overkill and unnecessary. Selecting the right tool ensures efficiency and safety.

Working Safely in the Environment

Ensure the work area is clear of obstructions and well-ventilated. This prevents accidents and promotes a safe working environment. If working in a confined space, ensure adequate ventilation to prevent the buildup of harmful fumes or dust from the work area.

Consider the presence of electrical hazards. If working in areas with exposed wiring or electrical components, take precautions to avoid electrical shocks or other potential hazards. Always use the impact wrench on a stable surface to avoid accidental movement or tipping over.