The benefits of regular inspections for drive shaft alignment

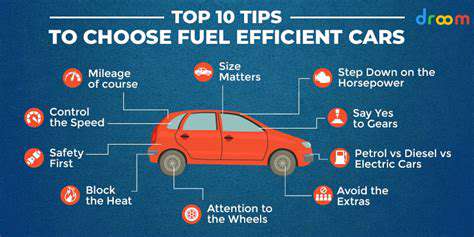

Enhanced Vehicle Efficiency and Fuel Economy

Optimizing Engine Performance

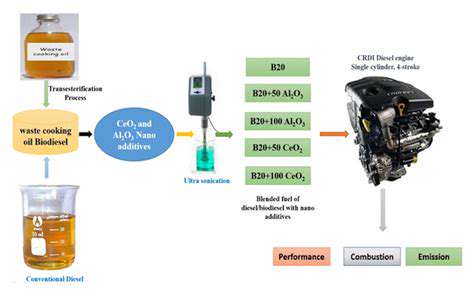

When it comes to squeezing every drop of performance from an engine, the devil's in the details. Precision tuning and hand-picking components like pistons, rods, and cylinder heads can work wonders - cutting friction while boosting power. Today's engines are smarter than ever, using clever tricks like variable valve timing and optimized combustion to deliver both punch and parsimony. The result? You'll visit the pump less often while leaving a smaller environmental footprint.

The brain behind this operation is the engine management system. Constantly crunching numbers, it tweaks fuel delivery and ignition timing on the fly to keep combustion at peak efficiency. With advanced sensors feeding real-time data, these systems make adjustments so precise they'd make a Swiss watch jealous.

Aerodynamic Design Enhancements

Air resistance is the silent thief of fuel economy. Sleek, wind-cheating shapes aren't just about looking fast - they actually make driving more efficient by reducing drag. Every curve of the bodywork, from the front bumper to the roofline, gets scrutinized in the wind tunnel.

Engineers employ clever tricks like strategically placed air deflectors and spoilers. These aren't just for show - they help air flow smoothly around the vehicle, reducing turbulence that can sap efficiency at highway speeds.

Transmission System Refinements

The latest transmission technology reads the road like a seasoned driver. Continuously variable and dual-clutch systems eliminate the jerky gear changes of old, seamlessly finding the perfect ratio for any situation.

The magic happens when the transmission keeps the engine humming in its sweet spot - that Goldilocks zone where power and efficiency perfectly balance. Compared to clunky old automatics or manuals, these modern systems can significantly cut fuel use without sacrificing performance.

Material Selection and Lightweighting

Car manufacturers are going on a diet, swapping heavy steel for featherweight materials like aluminum and carbon fiber. Every pound shaved from the chassis means less energy needed to get moving and stay moving.

This weight loss program isn't about vanity - shedding pounds directly translates to fewer stops at the gas station. Engineers walk a tightrope here, carefully ensuring that lighter doesn't mean weaker when it comes to safety and durability.

Tire Technology Advancements

Modern tires are engineering marvels that do more than just grip the road. Specially formulated compounds and innovative tread patterns minimize rolling resistance - the energy lost as tires deform on the pavement.

These aren't your grandfather's tires - they're precision instruments designed to cheat physics and save fuel with every revolution.

Improved Vehicle Electronics

Today's cars are rolling computers, and their electronic smarts extend to saving fuel. Regenerative braking systems capture energy normally lost as heat during stopping, feeding it back into the electrical system.

It's like getting a partial refund every time you hit the brakes - energy that would've gone to waste instead helps power your next acceleration. Even stability control systems chip in, preventing wasteful wheelspin to keep every drop of fuel working efficiently.

Fuel Economy and Environmental Impact

Better mileage isn't just about saving money - it's about saving the planet too. Every gallon not burned means fewer emissions clouding our skies and warming our climate.

The auto industry's green revolution combines clever engineering with environmental responsibility, proving you don't have to choose between performance and sustainability. These advances are steering us toward cleaner air and a healthier future.

Minimizing Noise and Vibration Issues

Understanding Noise and Vibration Sources

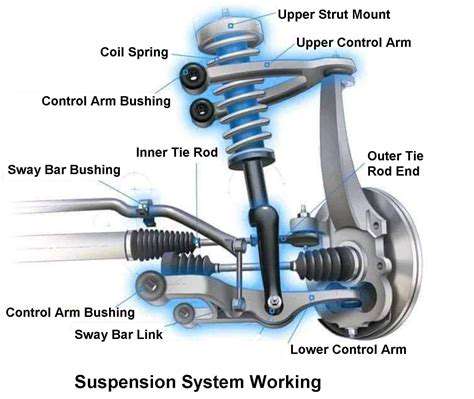

Noise and vibration issues in vehicles can be as complex as a symphony - but not nearly as pleasant. The key to solving them lies in playing detective, tracking down whether the culprit is misaligned parts, worn bearings, or structural resonance.

Environmental factors add another layer to the puzzle. Temperature swings, load changes, and even road conditions can all influence how components behave. Material choices matter too - some metals sing while others stay silent under stress.

The Importance of Early Detection

Catching noise and vibration problems early is like finding a small leak before it floods your basement. Proactive attention prevents minor issues from snowballing into major headaches that can leave you stranded.

Regular check-ups provide valuable insights into component health. Waiting until problems become obvious often means paying dearly in repairs and downtime.

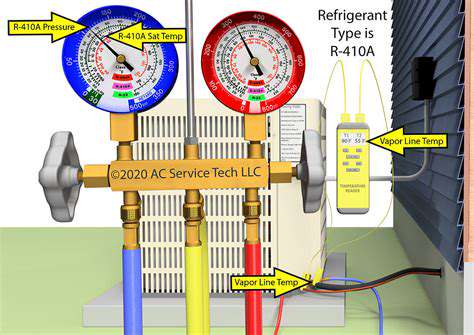

Inspection Techniques for Drive Systems

Diagnosing noise issues requires both art and science. Technicians might start with simple visual checks before breaking out sophisticated tools like vibration analyzers and ultrasonic detectors.

The most effective approach combines multiple methods - like a doctor using both stethoscope and MRI to understand what's happening beneath the surface.

Preventive Maintenance Strategies

An ounce of prevention truly is worth a pound of cure when it comes to noise and vibration. Routine tasks like proper lubrication and alignment can keep components working smoothly for years.

Implementing a scheduled maintenance plan tailored to your vehicle's needs helps avoid the domino effect where one worn part accelerates wear in others.

Impact on System Performance and Safety

Ignoring unusual sounds isn't just annoying - it can be downright dangerous. Excessive vibration can fatigue metal components over time, potentially leading to catastrophic failures.

For operators, constant noise isn't just a nuisance - prolonged exposure can lead to hearing damage and increased stress levels. Keeping things quiet and smooth isn't just about comfort - it's about health and safety too.

Cost Savings Through Proactive Maintenance

While maintenance costs money, neglecting it costs more. Small investments in regular check-ups can prevent massive repair bills down the road.

Well-maintained components last longer, delaying expensive replacements. More importantly, they keep you rolling instead of leaving you waiting for a tow truck.